Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

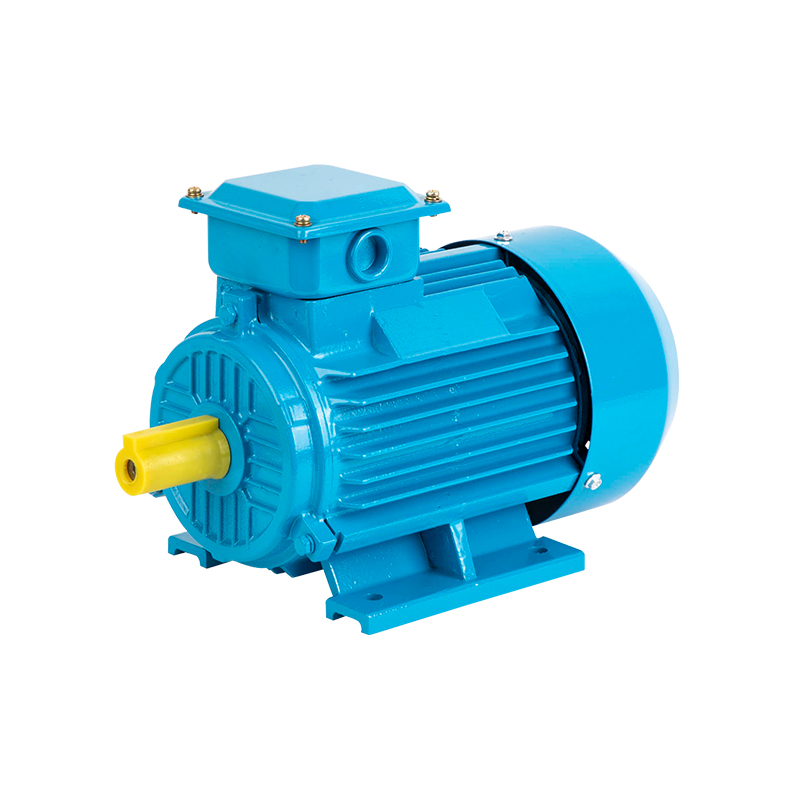

As industries continue to evolve, the demand for energy-efficient and high-performance electrical motors has never been greater. Among the various types of motors, the capacitor run asynchronous motor stands out due to its unique design that enhances operational efficiency and reliability. These motors, which use a capacitor for continuous operation, have become a staple in a wide range of industrial, commercial, and residential applications. In this article, we will explore the key advantages, technical specifications, and diverse applications of capacitor run asynchronous motors, as well as their role in the future of industrial motor technology.

Understanding the Capacitor Run Asynchronous Motor

A capacitor run asynchronous motor, also known as a capacitor-run induction motor, is an induction motor that employs a capacitor in the circuit to improve its efficiency during continuous operation. Unlike a capacitor start motor, where the capacitor is used solely for starting, a capacitor run motor maintains the capacitor in the circuit throughout the motor's operation. This design helps to increase the power factor and improve the overall efficiency of the motor by creating a more stable and consistent phase difference between the current and voltage.

In a typical asynchronous motor, the rotor is induced by a rotating magnetic field generated by the stator, causing it to turn. However, the efficiency of the motor can be limited due to the phase difference between the current and the voltage. The capacitor helps to address this issue by providing an additional phase shift, which improves the motor’s performance, reduces power loss, and increases torque. As a result, capacitor run asynchronous motors are capable of achieving better operational efficiency and delivering reliable performance across various applications.

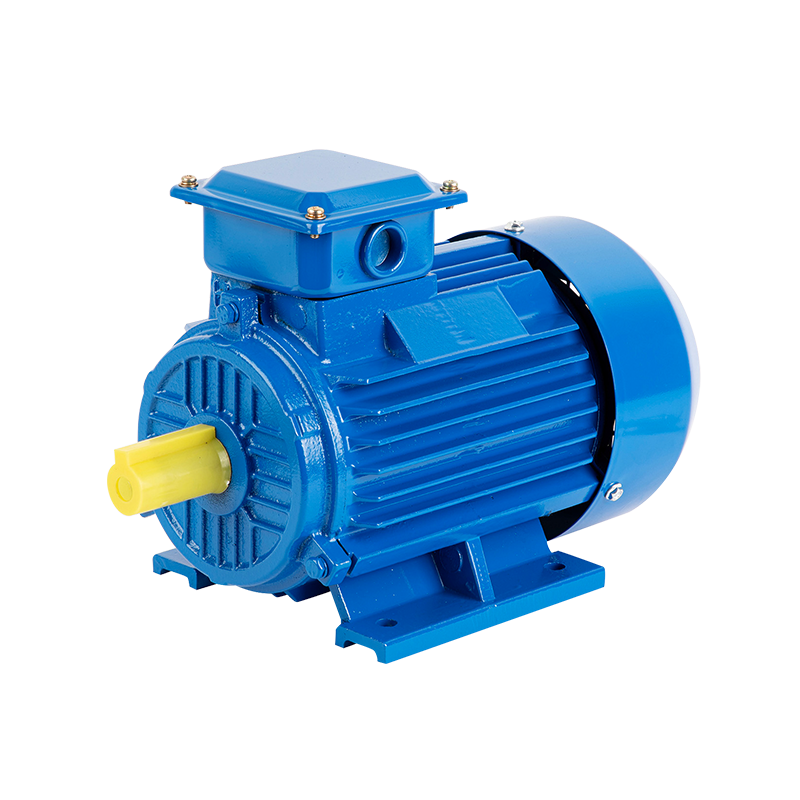

Advantages of Capacitor Run Asynchronous Motors

The use of capacitors in these motors offers several distinct advantages that make them ideal for both industrial and commercial uses. Some of the notable benefits include:

Enhanced Efficiency: One of the key advantages of the capacitor run asynchronous motor is its increased efficiency. The continuous operation of the capacitor reduces energy losses, making the motor more energy-efficient compared to standard induction motors. This efficiency translates into lower operational costs and a reduced carbon footprint for businesses looking to improve sustainability.

Improved Power Factor: The capacitor helps to improve the power factor of the motor, which is a measure of how effectively the electrical power is being used. By correcting the phase difference between the current and the voltage, the motor operates with a higher power factor, to better utilization of the available energy and reduced power wastage.

Stable and Reliable Performance: Capacitor run asynchronous motors offer more stable and consistent performance throughout their operation. The capacitor ensures that the motor runs smoothly, even under varying loads. This reliability is particularly important in applications where consistent operation is crucial, such as in industrial manufacturing processes.

Reduced Vibration and Noise: These motors are typically quieter and less prone to vibrations compared to other types of motors. This feature is particularly valuable in environments where noise reduction is important, such as in residential buildings, hospitals, or commercial spaces.

Compact and Cost-Effective: Capacitor run motors are generally more compact than other motor types, making them easier to integrate into various systems without taking up excessive space. Additionally, the initial cost of these motors is relatively low, while their long-term energy savings and reduced maintenance costs make them a cost-effective option in the long run.

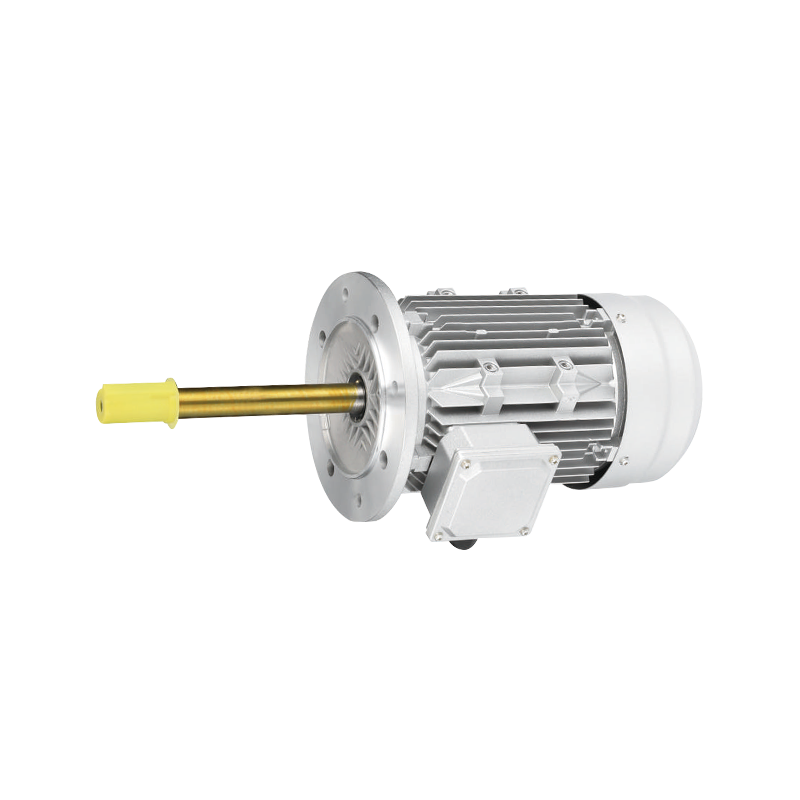

Key Applications of Capacitor Run Asynchronous Motors

The capacitor run asynchronous motor is versatile and can be used across a wide range of industries and applications. Some of the common uses include:

HVAC Systems: These motors are commonly used in heating, ventilation, and air conditioning (HVAC) systems, where reliable and efficient operation is essential. The ability to run smoothly and efficiently under varying load conditions makes them ideal for driving fans, blowers, and compressors in HVAC applications.

Water Pumps: Capacitor run motors are also widely used in water pump systems, both in industrial and residential applications. Their ability to deliver consistent performance under load makes them well-suited for use in irrigation systems, sewage pumps, and water treatment facilities.