Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

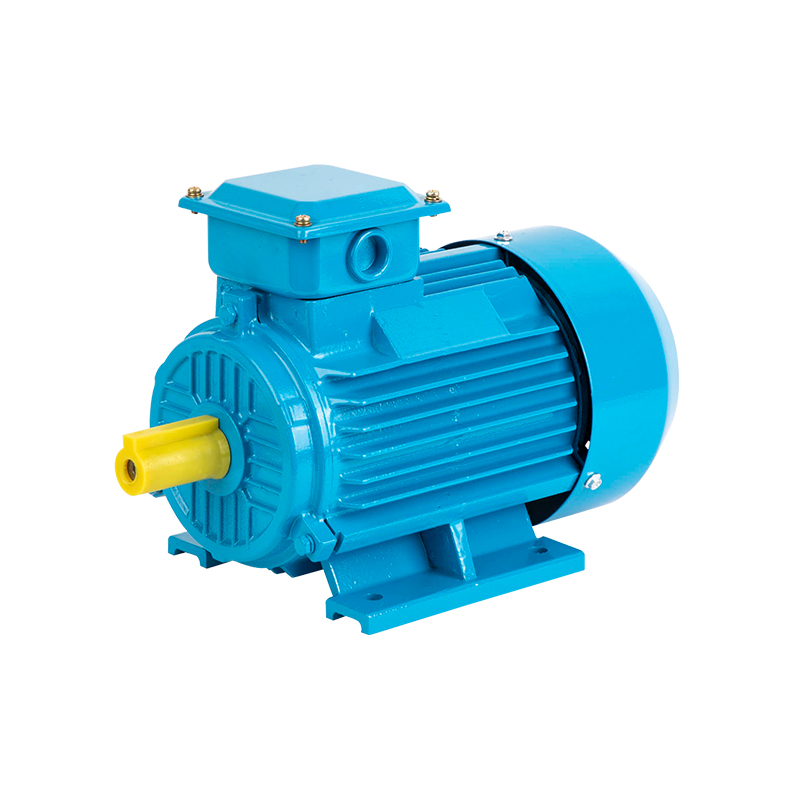

In the evolving landscape of industrial motors, the aluminum shell three-phase asynchronous motor stands out as a pivotal development that has transformed a wide range of industries. Known for its durability, efficiency, and lightweight construction, the aluminum shell three-phase asynchronous motor has become a staple in applications where reliability and performance are paramount. This article delves into the latest innovations, market trends, and future prospects of these motors, highlighting their role in the energy-efficient and cost-effective operation of industrial machinery.

Understanding Aluminum Shell Three-Phase Asynchronous Motors

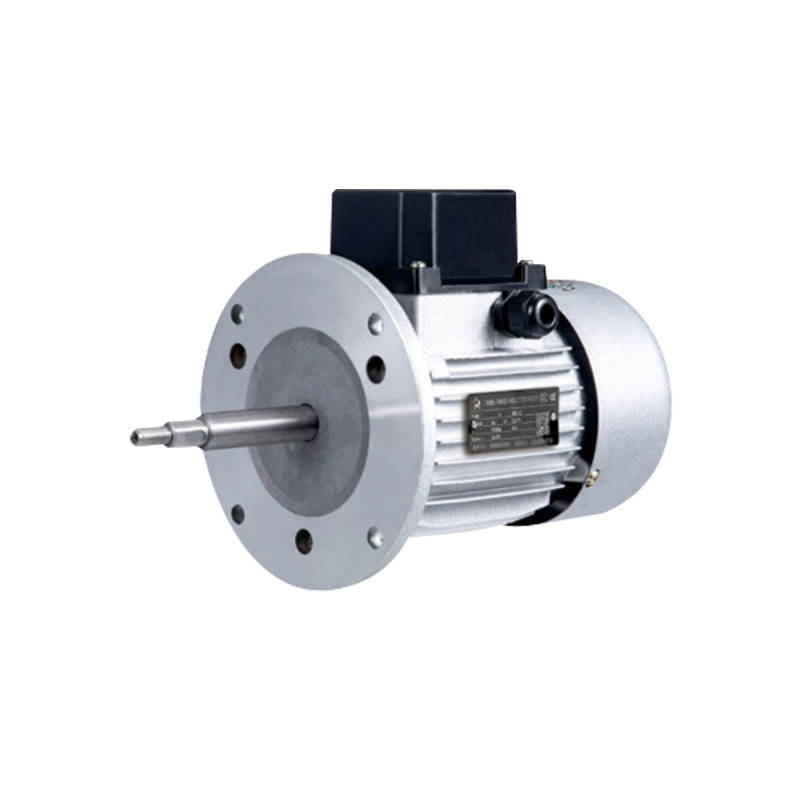

The three-phase asynchronous motor, commonly referred to as an induction motor, is a type of electric motor that operates on alternating current (AC). It is called "asynchronous" because the rotor does not rotate at the same speed as the stator's magnetic field but instead at a slightly lower speed, depending on the load. These motors are widely used in industrial applications due to their simplicity, durability, and relatively low maintenance requirements.

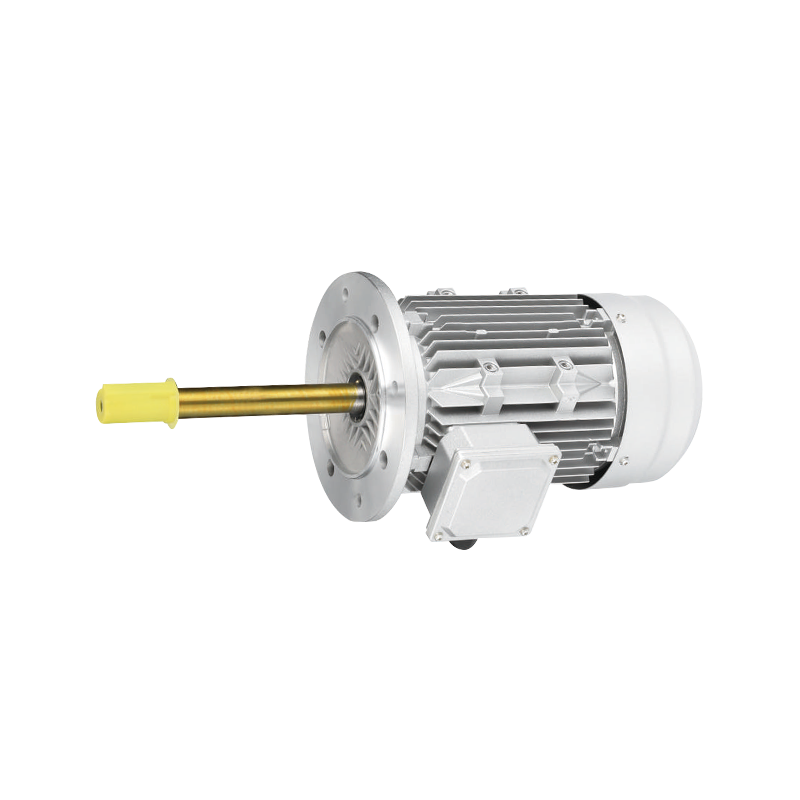

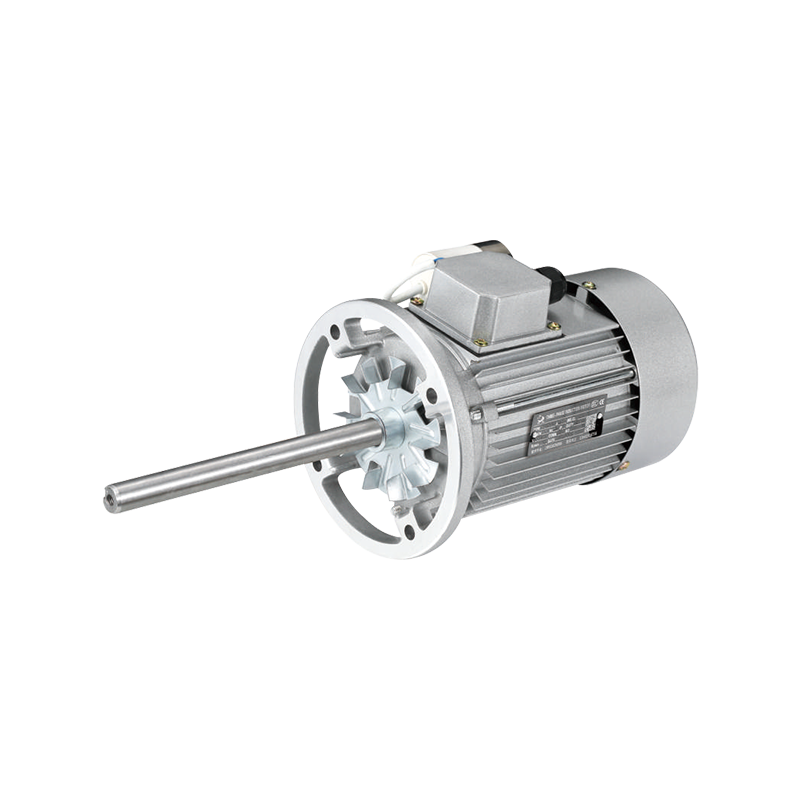

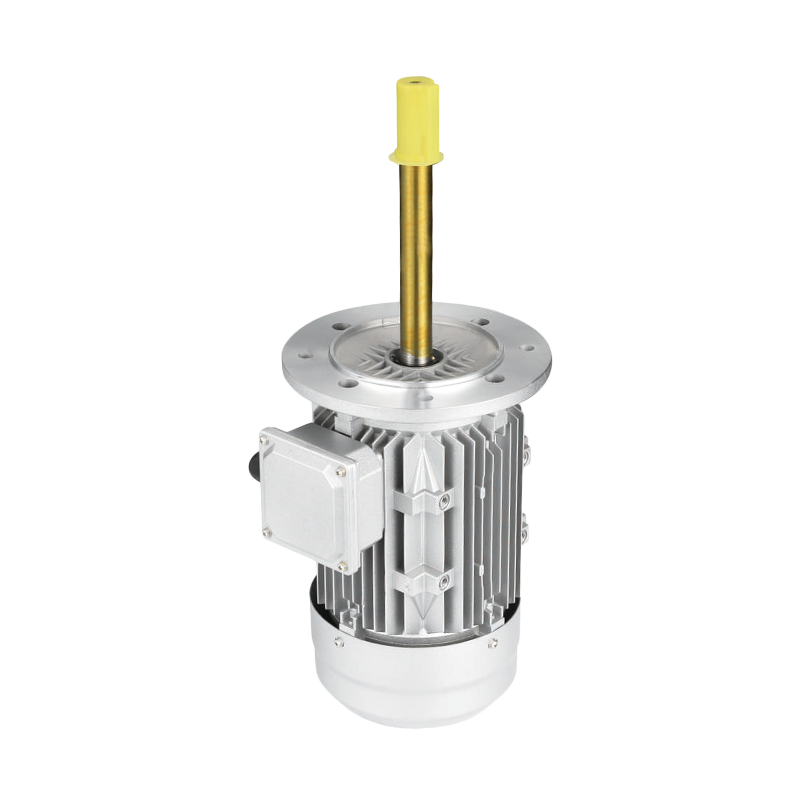

The term "aluminum shell" refers to the motor housing, which is constructed from aluminum. Aluminum is an ideal material for motor casings due to its lightweight properties, heat conductivity, and resistance to corrosion. The aluminum shell also reduces the overall weight of the motor, making it easier to handle and install, which is a crucial advantage in both commercial and industrial settings.

Advantages of Aluminum Shell Three-Phase Asynchronous Motors

Several key benefits contribute to the growing popularity of aluminum shell three-phase asynchronous motors. These include:

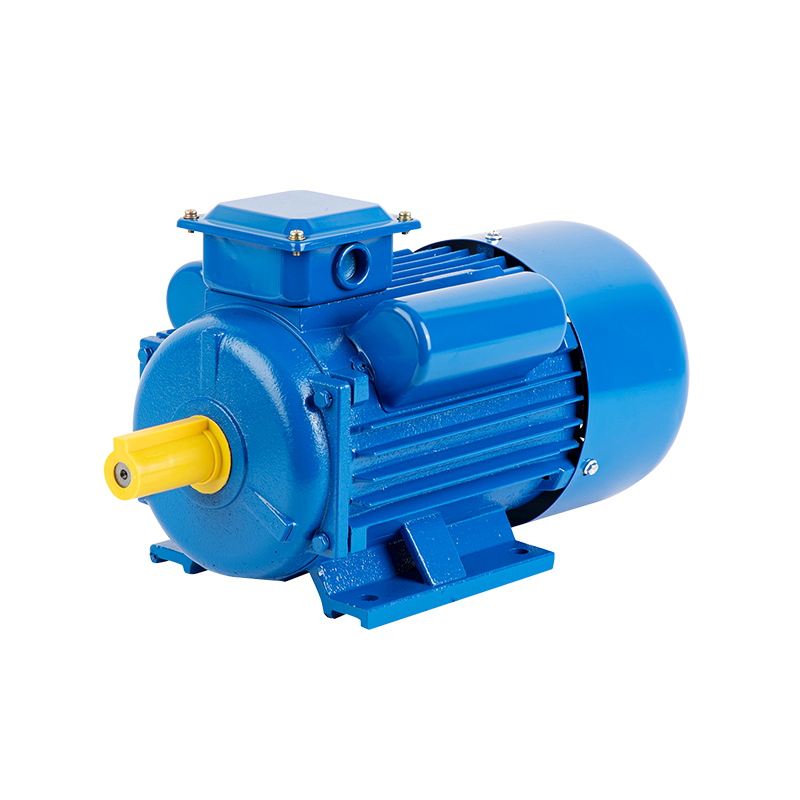

Lightweight and Cost-Effective: Aluminum is a lightweight material that helps reduce the overall weight of the motor, making it easier to transport, install, and maintain. This reduces shipping and installation costs, making these motors a cost-effective option for many applications.

Enhanced Durability and Corrosion Resistance: The aluminum casing provides protection against environmental factors such as moisture and corrosive agents. This makes aluminum shell motors ideal for use in industries like chemicals, food processing, and marine applications, where motors are often exposed to harsh conditions.

Efficient Heat Dissipation: Aluminum is an conductor of heat, ensuring that the motor remains cool during operation. Efficient heat dissipation helps prolong the motor's lifespan and maintain performance, even under heavy loads or extended use.

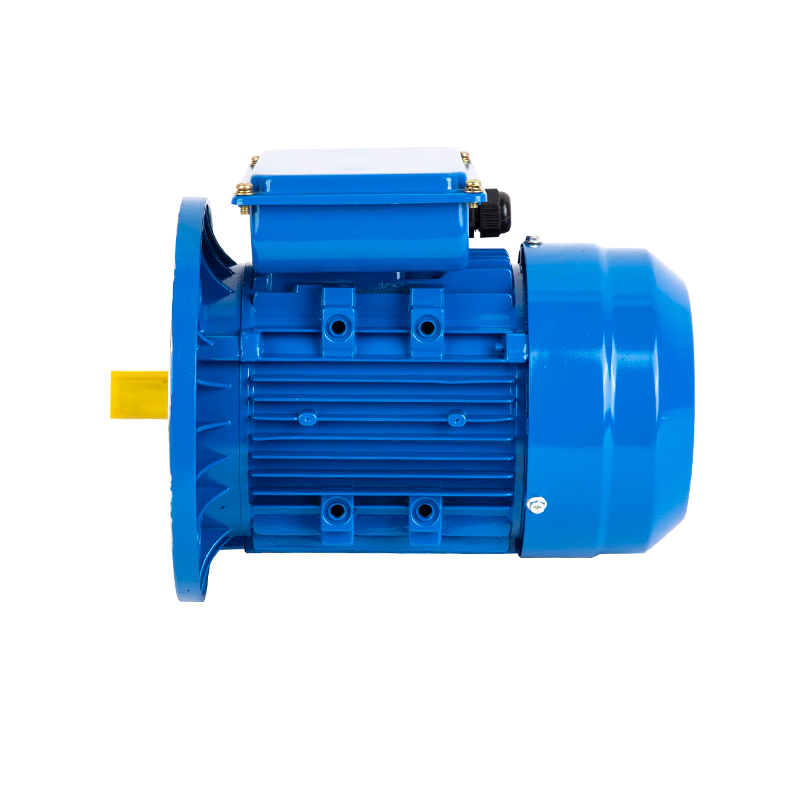

Energy Efficiency: Asynchronous motors, especially those with high-quality aluminum casings, are designed to optimize energy consumption. They are highly efficient, reducing operational costs and contributing to energy savings. As industries increasingly focus on sustainability and energy conservation, these motors have become an attractive option for reducing carbon footprints.

Low Maintenance Requirements: The robust construction of aluminum shell motors and their simple design means that they require minimal maintenance. This makes them ideal for continuous operation in environments where downtime can be costly.

Applications Across Various Industries

The aluminum shell three-phase asynchronous motor is used in a diverse range of industries, thanks to its versatility and reliability. Some of the common applications include:

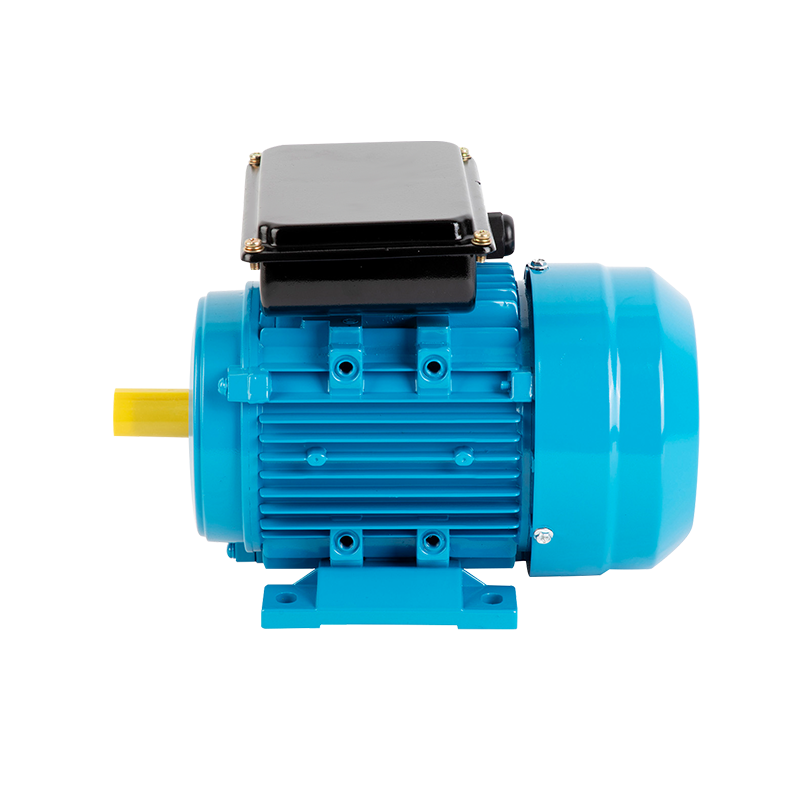

Pumps and Compressors: These motors are often used to drive pumps and compressors in industries such as water treatment, HVAC, and oil and gas. The motor's high torque and efficiency make it ideal for these applications, where continuous operation and energy efficiency are critical.

Conveyors: Aluminum shell motors are widely used to power conveyor belts in manufacturing and logistics. Their lightweight design and ability to handle heavy loads without compromising efficiency make them ideal for transporting materials over long distances.

Fans and Ventilation Systems: In industrial settings, aluminum shell three-phase motors are commonly used to drive fans and ventilation systems, ensuring proper air circulation in factories, warehouses, and other large facilities.

Machine Tools: Many machine tools, such as milling machines, lathes, and grinders, rely on these motors for smooth and precise operation. Their reliability and consistent performance make them a crucial component of manufacturing processes.

Agriculture: In the agricultural sector, these motors power equipment such as irrigation pumps, feed mills, and grain elevators. The durability and energy efficiency of aluminum shell motors are essential for ensuring smooth operations in demanding agricultural environments.