What Makes a High-Quality Meat Grinder Motor Essential for Industrial Use?

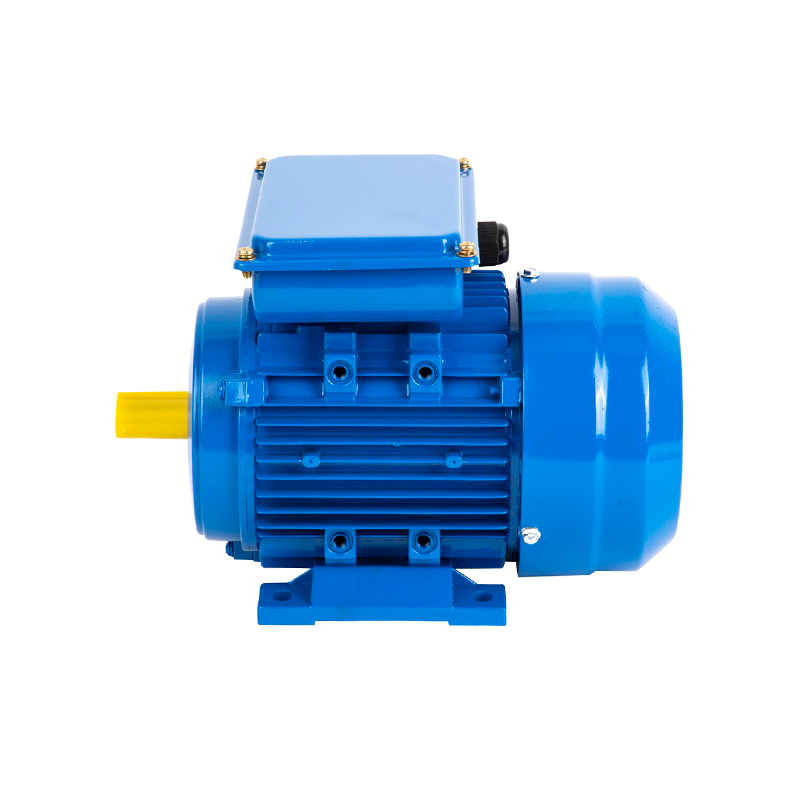

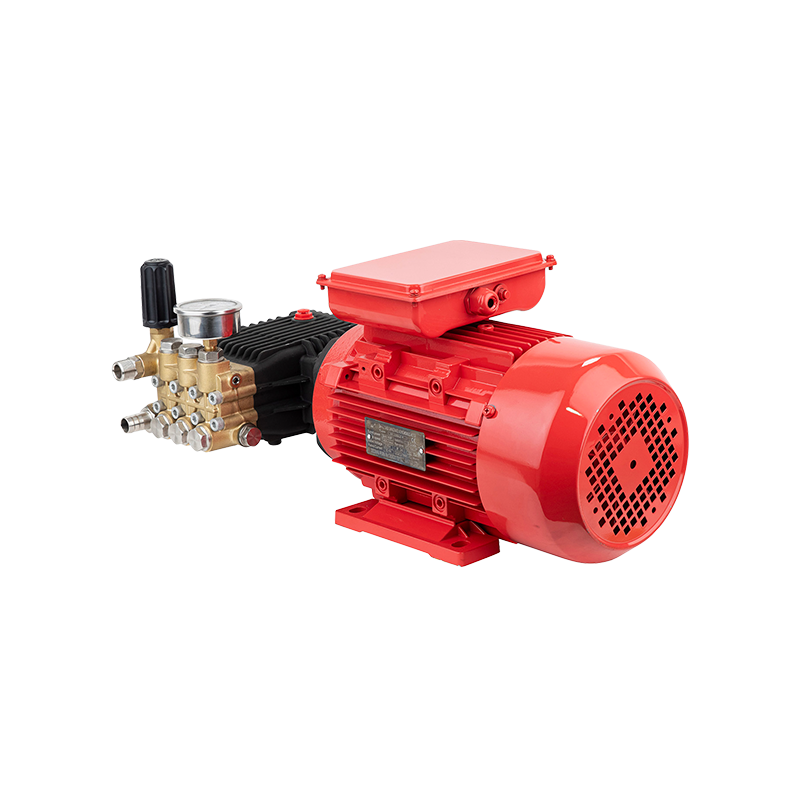

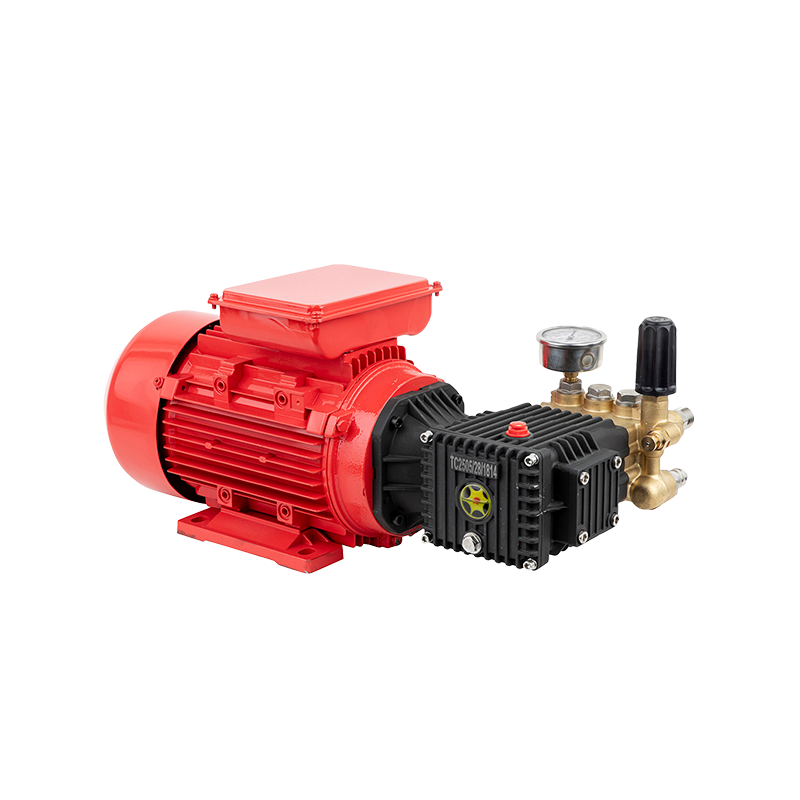

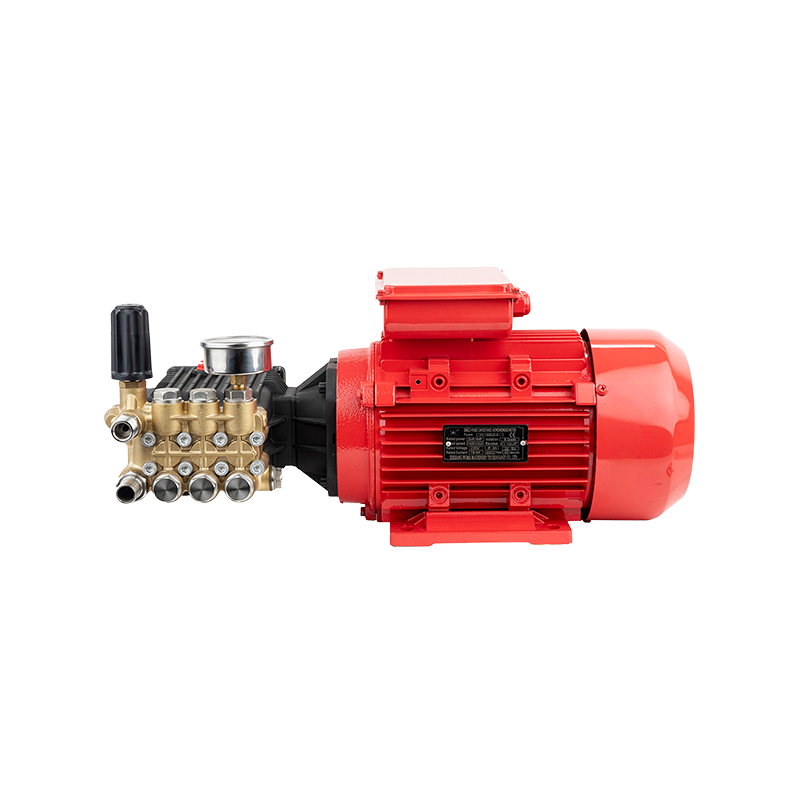

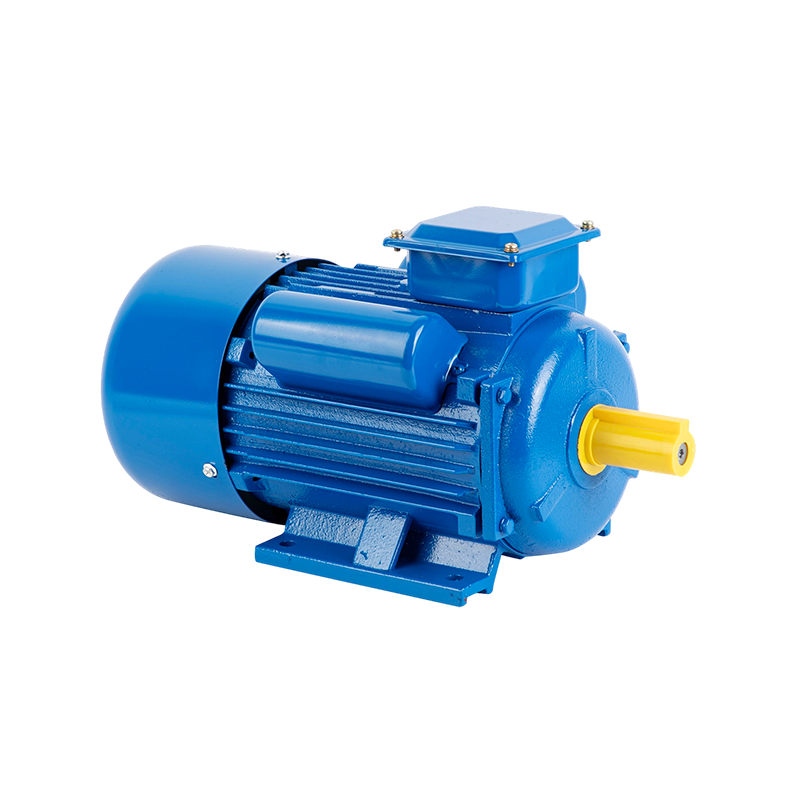

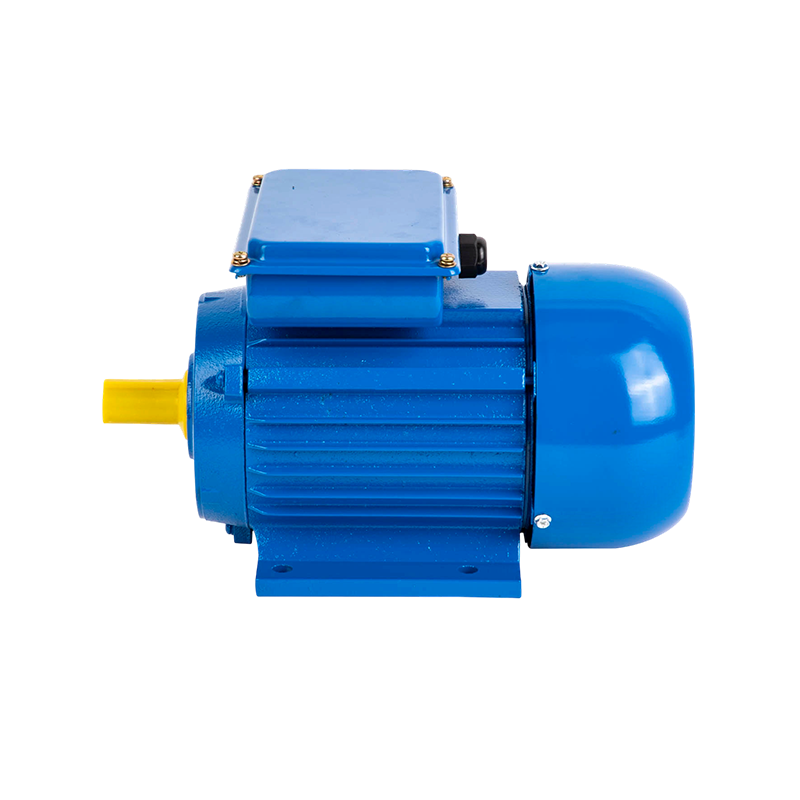

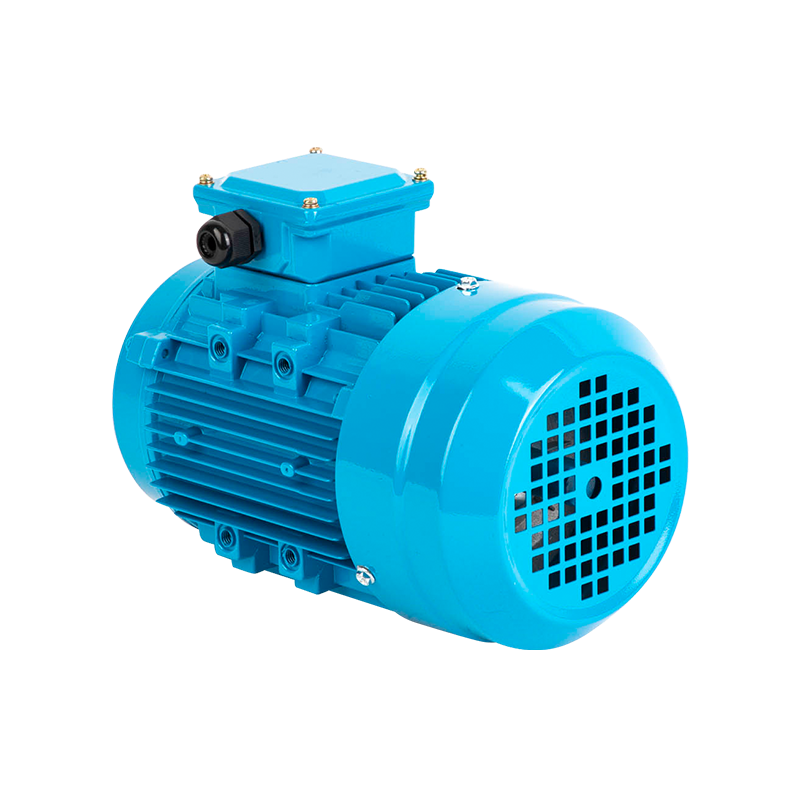

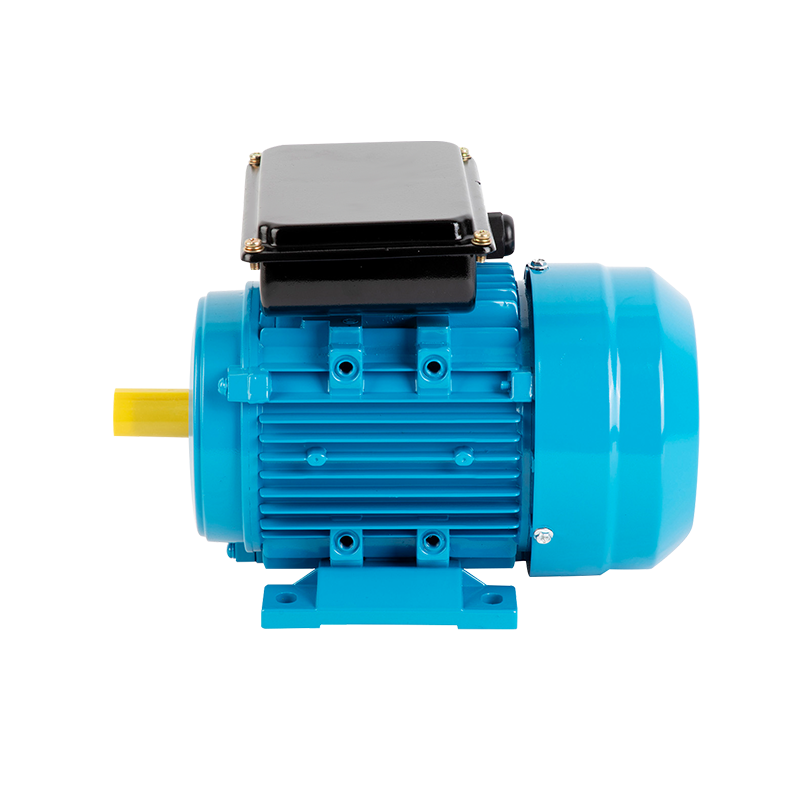

In industrial food processing, the motor is the heart of any meat grinder. A reliable Meat Grinder Motor ensures consistent torque, smooth operation, and long-lasting performance under heavy workloads. At our manufacturing facility, we focus on building Double Value Capacitor Asynchronous Motors that can handle prolonged operation without overheating or loss of efficiency. These motors are engineered to maintain good speed and power, allowing large-scale meat grinders to operate efficiently, whether in butcheries, food factories, or commercial kitchens.

How Does an Electric Motor Improve the Efficiency of Meat Grinders?

An Electric Motor for Meat Grinder offers precision, energy efficiency, and reliable performance compared to manual or low-quality alternatives. Our motors are designed to deliver high torque even at low speeds, ensuring meat is processed uniformly without straining the motor. The integration of double value capacitors enhances starting torque and operational stability, allowing industrial meat grinders to handle tougher cuts of meat with minimal vibration. This translates into higher productivity, reduced downtime, and lower maintenance costs for operators.

What Are the Advantages of a Double Value Capacitor Asynchronous Motor in Meat Grinders?

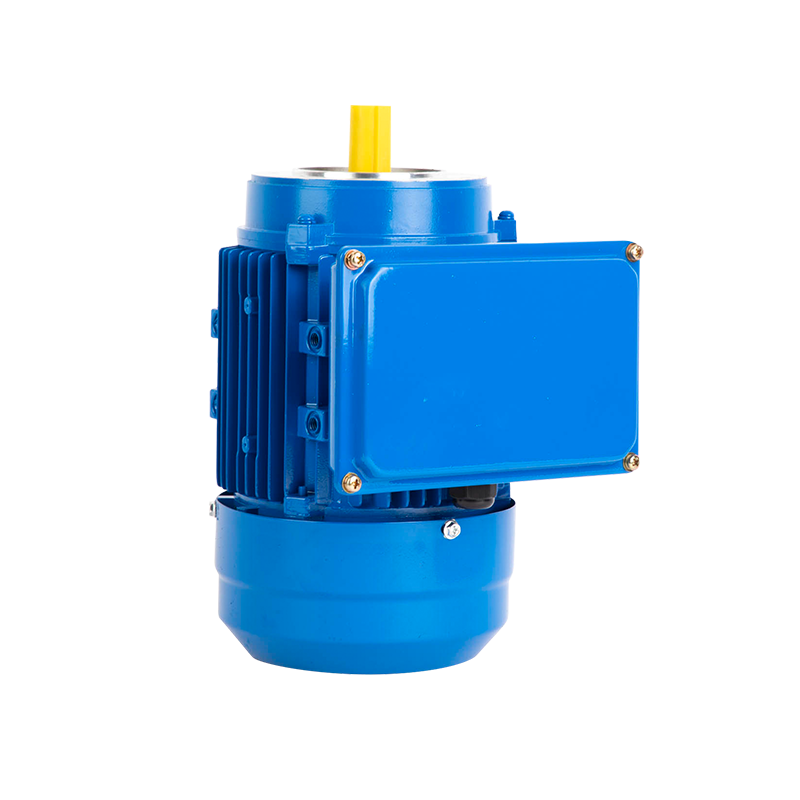

The Double Value Capacitor Asynchronous Motor is particularly suitable for heavy-duty industrial grinders. Unlike standard single-capacitor motors, our design ensures smoother acceleration, higher starting torque, and reduced current surges, protecting both the motor and the connected machinery. This type of motor can maintain a stable operational speed even under fluctuating loads, which is essential in meat processing lines where consistency directly impacts product quality. By investing in this motor type, businesses gain durability, efficiency, and energy savings.

How Does the Motor Design Enhance Durability and Longevity?

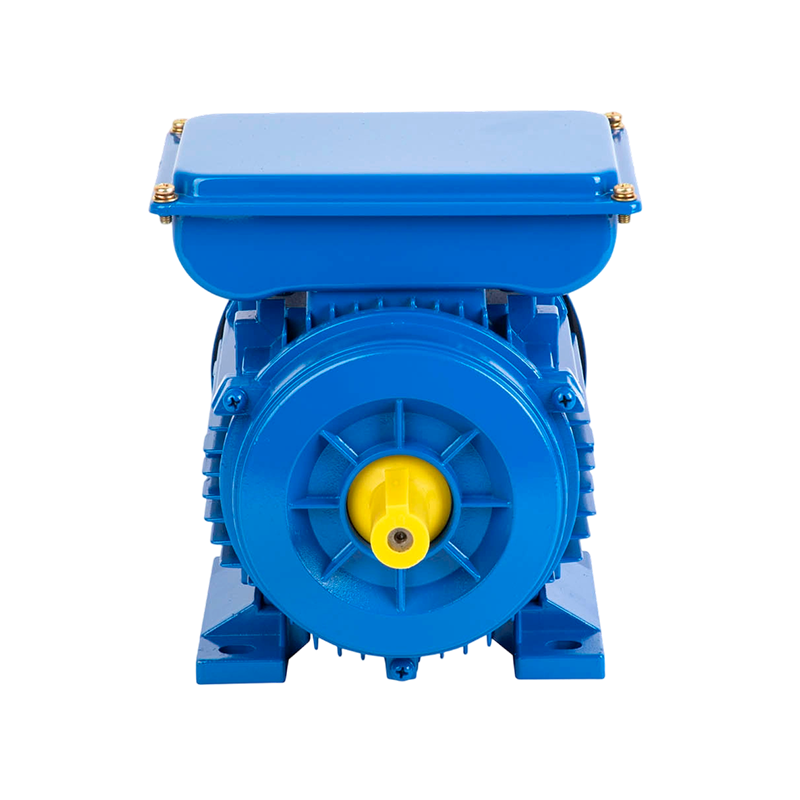

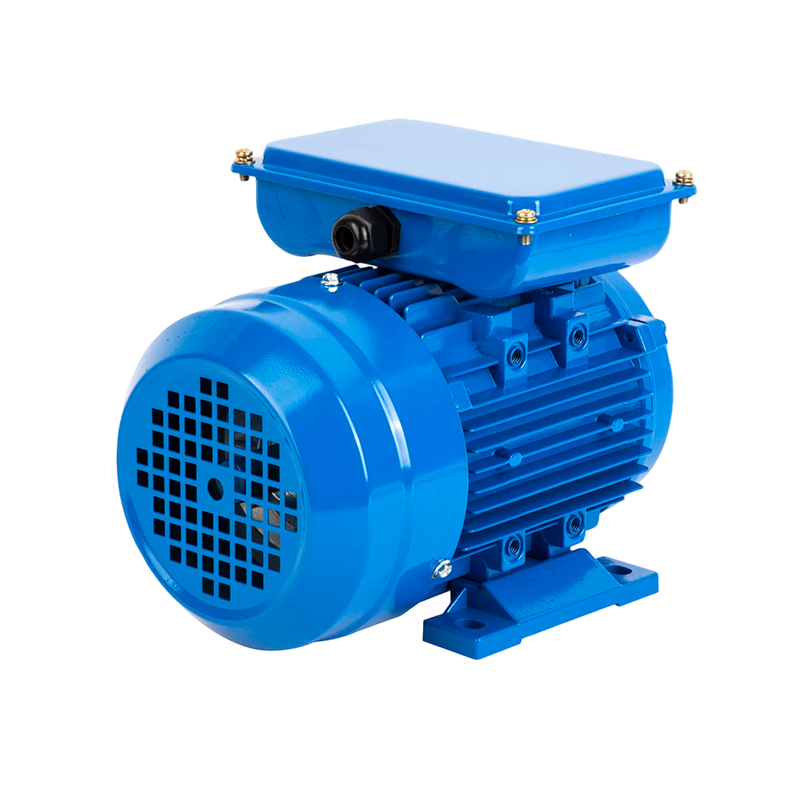

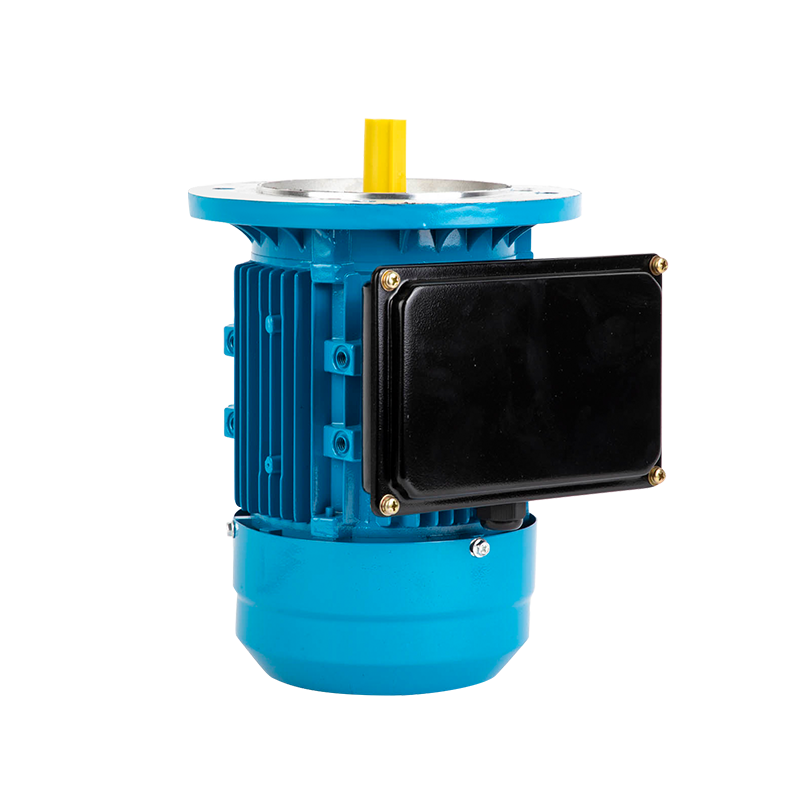

Durability is key for Industrial Meat Grinder applications. Our motors are built with high-grade materials for both the rotor and stator, ensuring resistance to mechanical wear and heat. Advanced cooling designs, including strategically placed ventilation slots, minimize heat buildup and extend motor life. Additionally, precision-balanced rotors reduce vibration, lowering mechanical stress and contributing to quieter operation. This careful engineering ensures that even in continuous, high-demand environments, the motor maintains peak performance.

Can This Motor Handle High-Volume Meat Processing Operations?

Absolutely. Our Electric Motor for Meat Grinder is designed for high-volume operations. With good torque characteristics and robust capacitor-enhanced starting capability, it can process large batches of meat efficiently. Industrial users often report faster production cycles and reduced operational interruptions, thanks to the motor's ability to sustain heavy workloads without overheating. This is particularly valuable in meat processing plants or large commercial kitchens where downtime can significantly affect productivity and profits.

What Applications Are Suited for This Motor Type?

These motors are versatile and fit a wide range of meat processing equipment. They power commercial and industrial meat grinders, mixers, and mincers used in butcher shops, food production factories, and meat packaging lines. The stable performance and high torque make them ideal for grinding all types of meat, including tougher cuts, without compromising product quality. In addition, the asynchronous motor design is compatible with various voltage configurations and industrial safety standards, making it adaptable to different factory environments.

How Does Our Manufacturing Expertise Ensure Quality and Consistency?

As a manufacturer, we control every step of production to ensure meat grinder motors meet rigorous quality standards. Each motor undergoes extensive testing for efficiency, torque stability, and temperature tolerance. We optimize winding techniques, capacitor selection, and rotor design to improve energy efficiency and minimize mechanical wear. Our focus on precision engineering and quality control ensures that every motor leaving the factory delivers long-lasting, reliable performance suitable for demanding industrial applications.

Why Choose Our Industrial Meat Grinder Motors?

Choosing our motors means investing in reliable performance, energy efficiency, and longevity. Our Meat Grinder Mixer Double Value Capacitor Asynchronous Motor provides industrial users with higher productivity, reduced maintenance, and consistent operational stability. By combining advanced motor technology with rigorous manufacturing standards, we offer a solution that meets the expectations of professional meat processors worldwide.