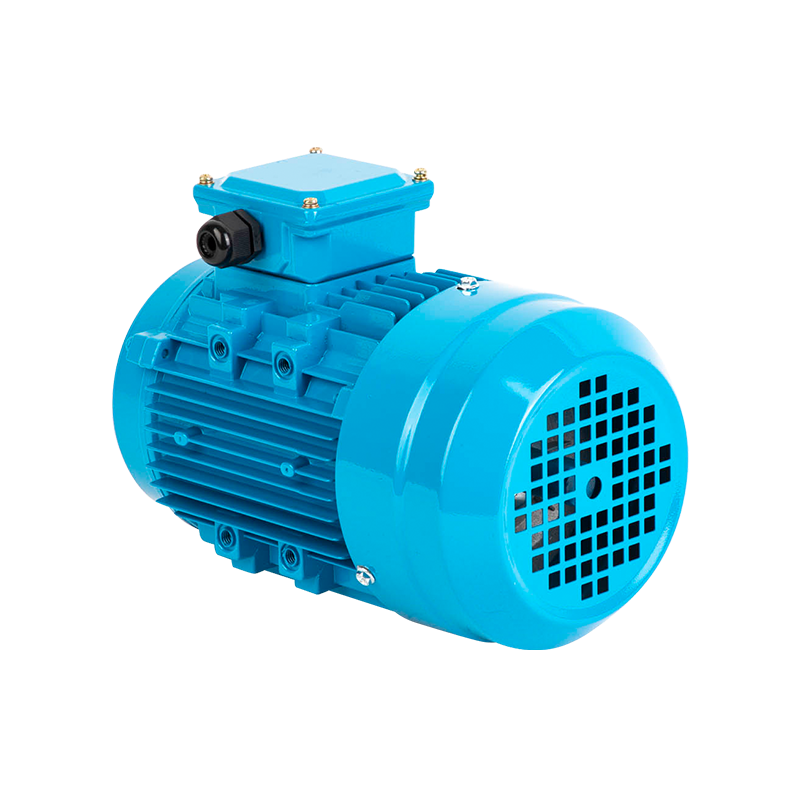

High Speed High Torque Motor: Balancing Power and Precision

A High Speed High Torque Motor is designed to deliver the special combination of rapid rotation and strong torque output. Traditionally, motors are optimized for either speed or torque, but advanced engineering now allows the balance of both. From a manufacturer's standpoint, these motors are built with enhanced rotor designs, precision bearings, and advanced insulation systems to withstand the mechanical stress of high-speed operations.

Industries such as robotics, CNC machinery, textile manufacturing, and packaging systems benefit greatly from these motors. For example, in robotic arms, the ability to maintain torque even at high speeds ensures precise movement without losing stability. In CNC machines, it enables smooth cutting and drilling across a wide range of materials.

One of the greatest advantages manufacturers highlight is energy efficiency under load. By maintaining torque stability, high speed high torque motors reduce wasted energy, ensuring both productivity and cost savings.

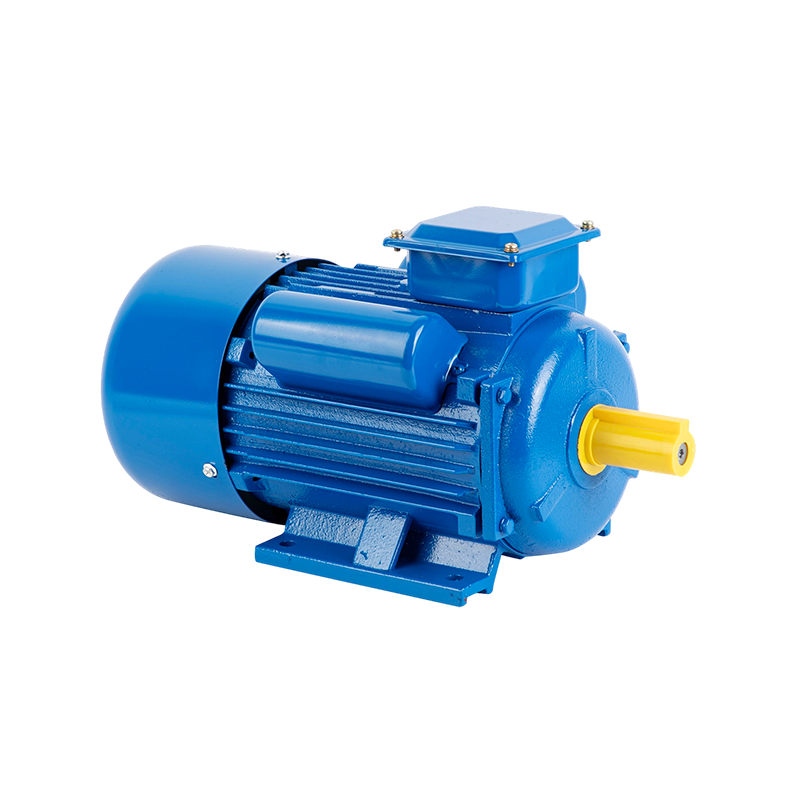

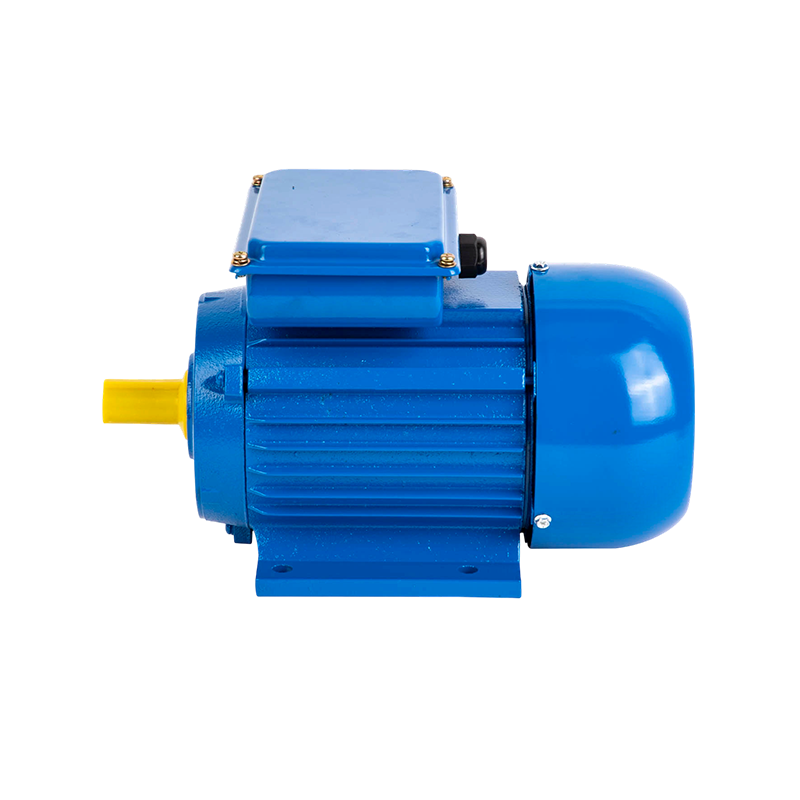

High Speed 3 Phase Motor: Industrial Backbone for Heavy Applications

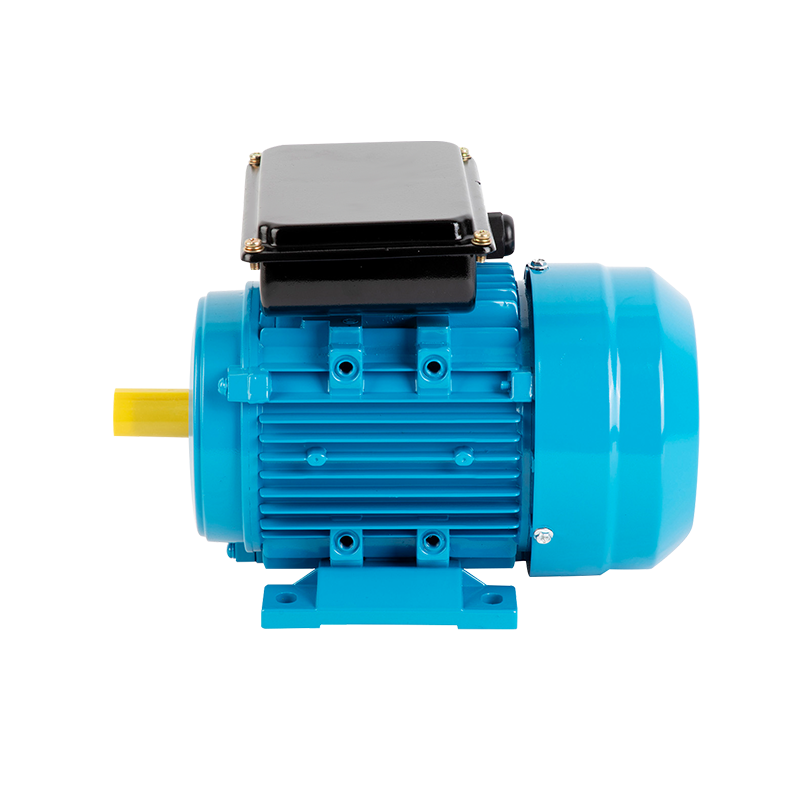

The High Speed 3 Phase Motor has long been the backbone of modern industries due to its reliability, robustness, and ability to handle large-scale power demands. Unlike single-phase motors, 3-phase motors provide a smoother power supply, which directly reduces vibrations, heat generation, and maintenance needs.

For industries like pumps, compressors, fans, and conveyor systems, the high speed 3 phase motor is especially valuable. Its balanced performance ensures consistent operation even under continuous heavy loads. From a manufacturer's perspective, producing these motors requires adherence to international efficiency standards (IE2, IE3, and IE4), ensuring buyers receive equipment that meets sustainability and cost-reduction goals.

Another key selling point is scalability. High speed 3 phase motors can be manufactured in a wide range of power ratings, from fractional kilowatts for compact machinery to hundreds of kilowatts for large industrial systems. This makes them attractive for procurement managers seeking standardized yet versatile solutions across multiple facilities.

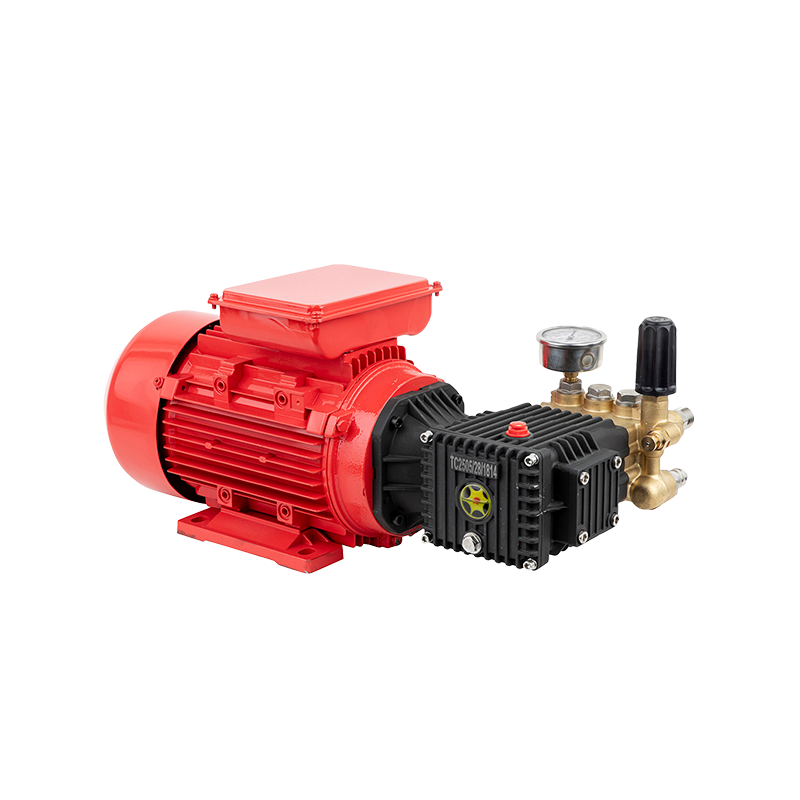

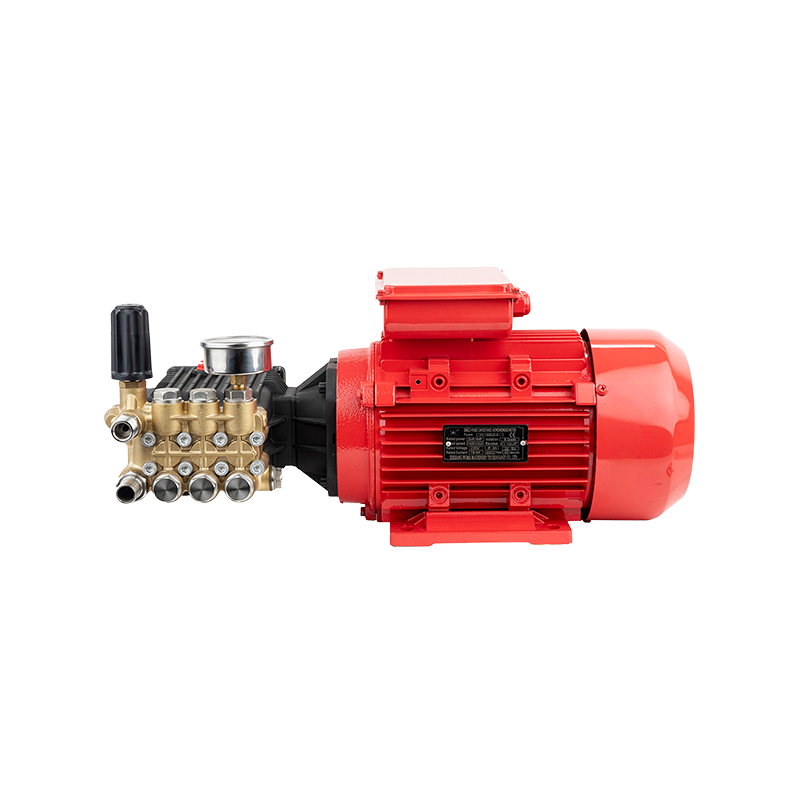

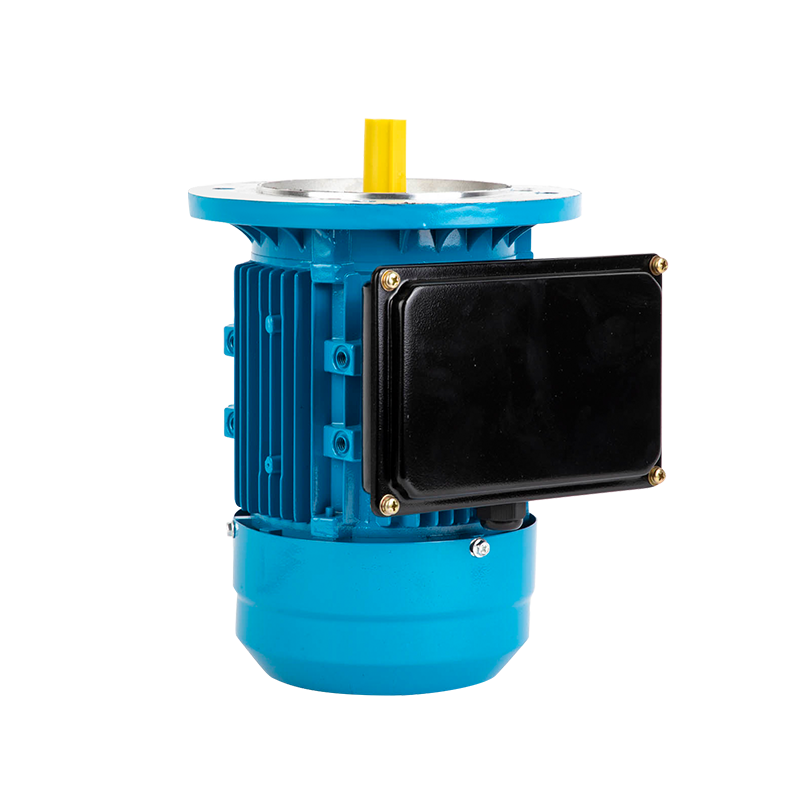

Electric Shaft Motor: Redefining Flexibility and Customization

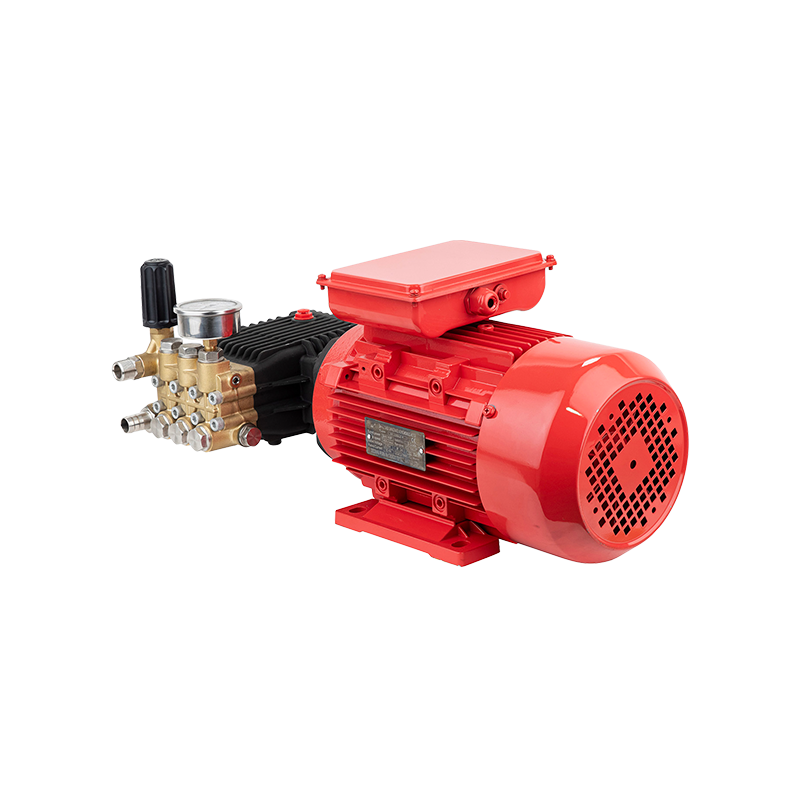

The Electric Shaft Motor is a relatively specialized solution designed for applications that require extended shaft lengths, compact installations, or direct coupling to mechanical systems. Manufacturers develop these motors with longer shaft extensions, reinforced bearings, and custom housing designs to meet unique installation requirements.

Applications include pumps, blowers, conveyor rollers, and textile machines, where direct shaft connection simplifies machine structure and reduces additional transmission components. For buyers, the advantage is reduced system complexity, fewer points of failure, and easier maintenance.

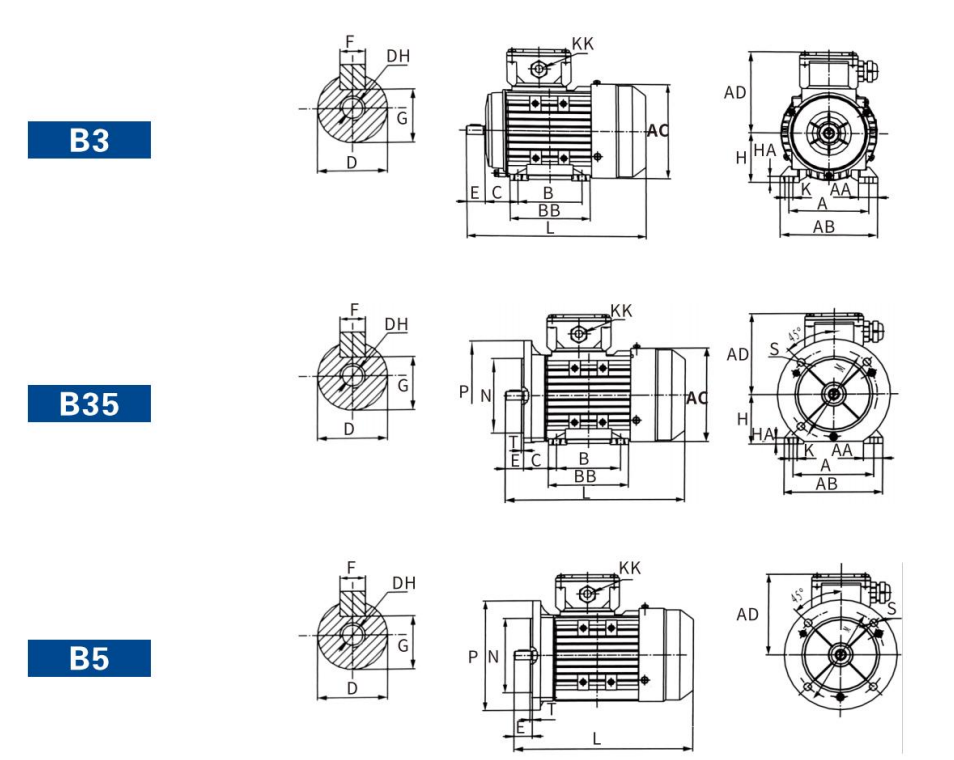

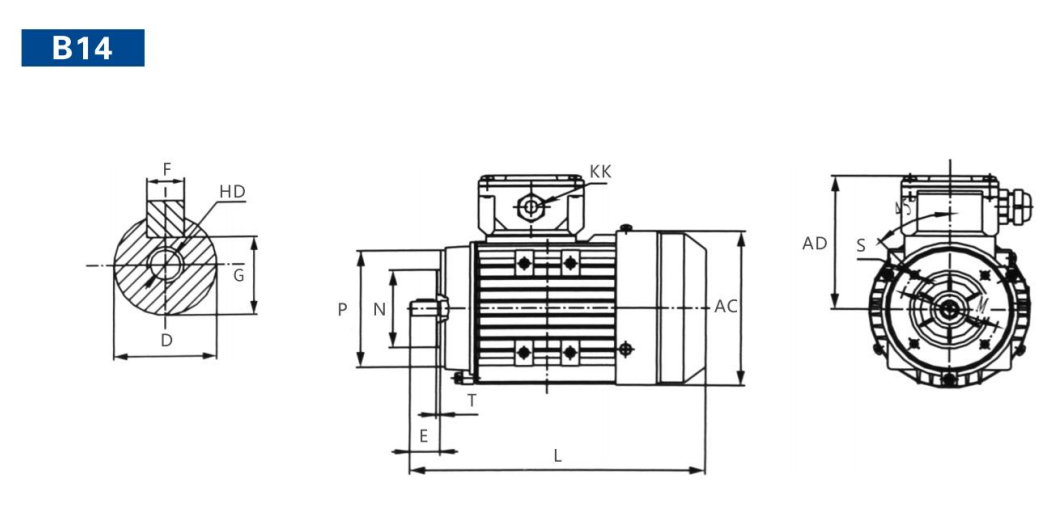

From a factory's standpoint, offering electric shaft motors demonstrates the ability to custom-engineer solutions. Many buyers require OEM or ODM services where shaft length, mounting options, and motor power can be tailored to specific projects. This customization is a major driver for wholesale partnerships, as it allows end-users to optimize equipment design.

Manufacturer's Competitive Edge

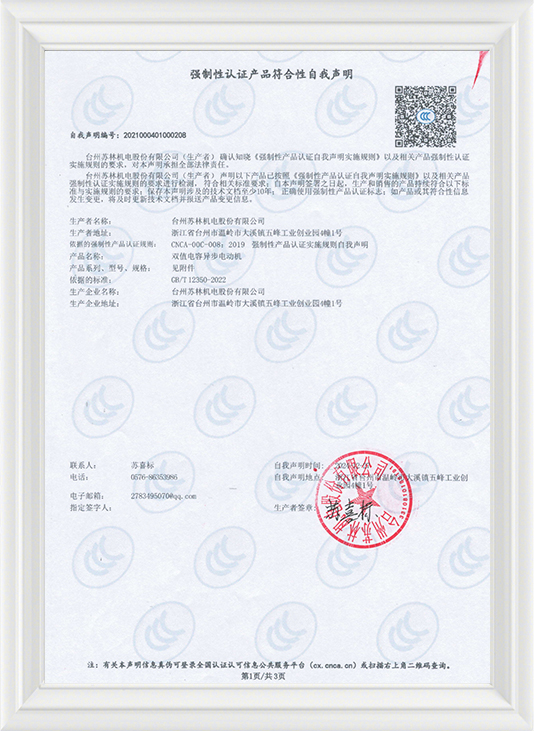

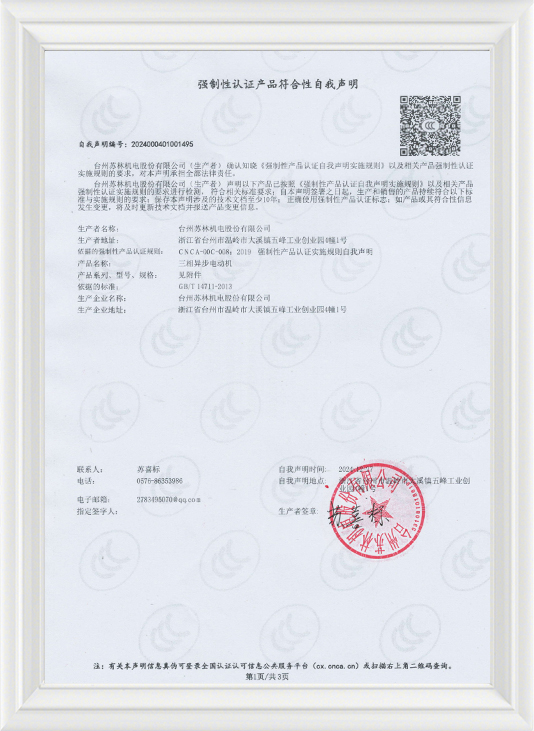

When discussing High Speed High Torque Motors, High Speed 3 Phase Motors, and Electric Shaft Motors, professional manufacturers emphasize several advantages:

- Precision Engineering – Using CNC machining and automated winding ensures consistency and reliability in motor performance.

- Energy Efficiency – Compliance with IE3/IE4 efficiency classes helps reduce operational costs.

- Material Quality – Employing high-grade silicon steel, copper windings, and heat-resistant insulation improves lifespan.

- Customization Services – OEM/ODM options for shaft length, frame size, and voltage/frequency allow adaptation across global markets.

- After-Sales Support – Providing technical consultation, installation guidance, and spare parts availability strengthens buyer confidence.

Market Trends and Buyer Considerations

The global demand for high performance electric motors is being driven by automation, renewable energy projects, and stricter energy efficiency regulations. Buyers considering wholesale orders should evaluate:

- Load requirements (whether speed or torque is the priority).

- Energy efficiency class (higher classes reduce long-term operating costs).

- Application compatibility (shaft design, motor frame, and mounting).

- Manufacturer reputation (certifications, warranty, and global support).

With the right choice, buyers can achieve not only outstanding machine performance but also long-term savings through reduced maintenance and lower energy consumption.

The combination of High Speed High Torque Motors, High Speed 3 Phase Motors, and Electric Shaft Motors highlights how advanced engineering is reshaping the industrial motor sector. These motors offer speed, torque, efficiency, and flexibility, making them indispensable in modern automation and manufacturing.