User Questions and Manufacturer Insights on Heat Shrinking Machine Motors

1. What makes the Heat Shrinking Machine Double Value Capacitor Asynchronous Motor different from standard motors?

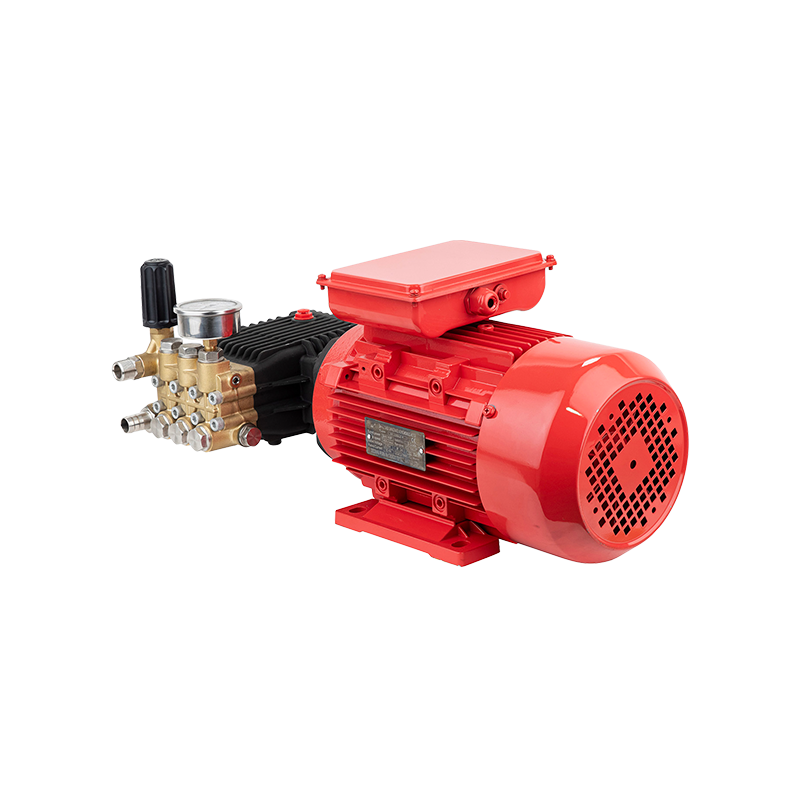

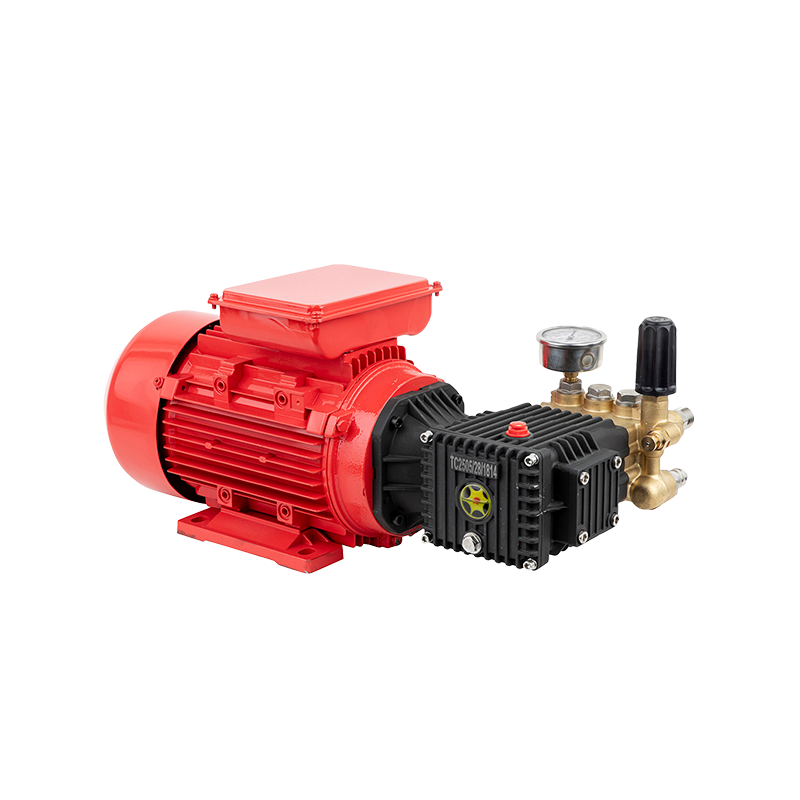

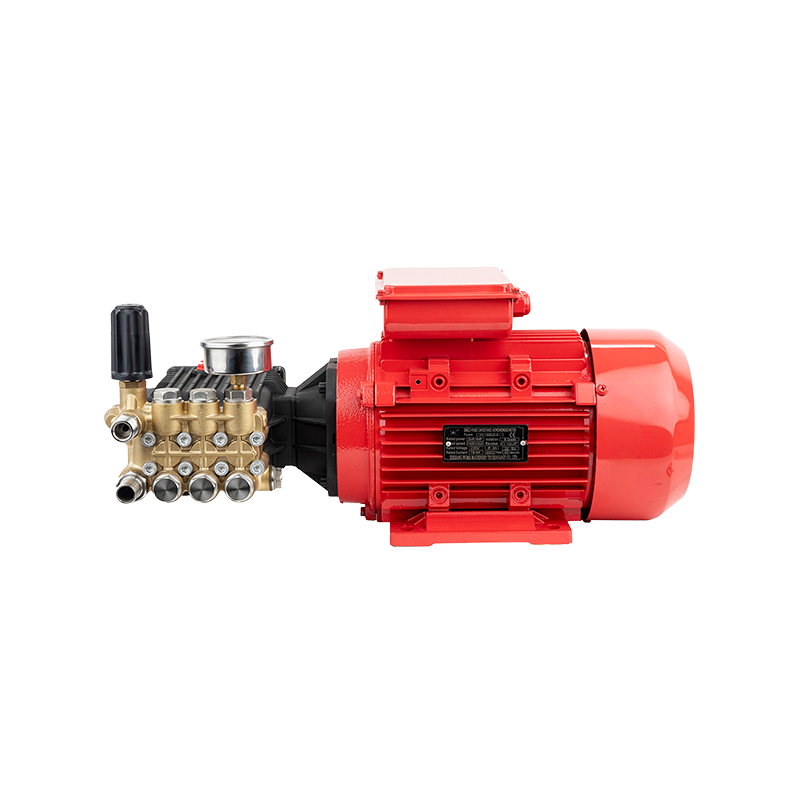

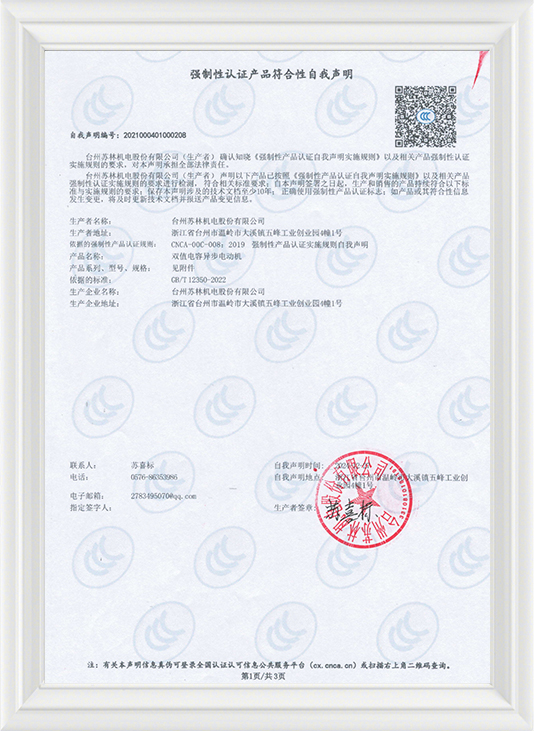

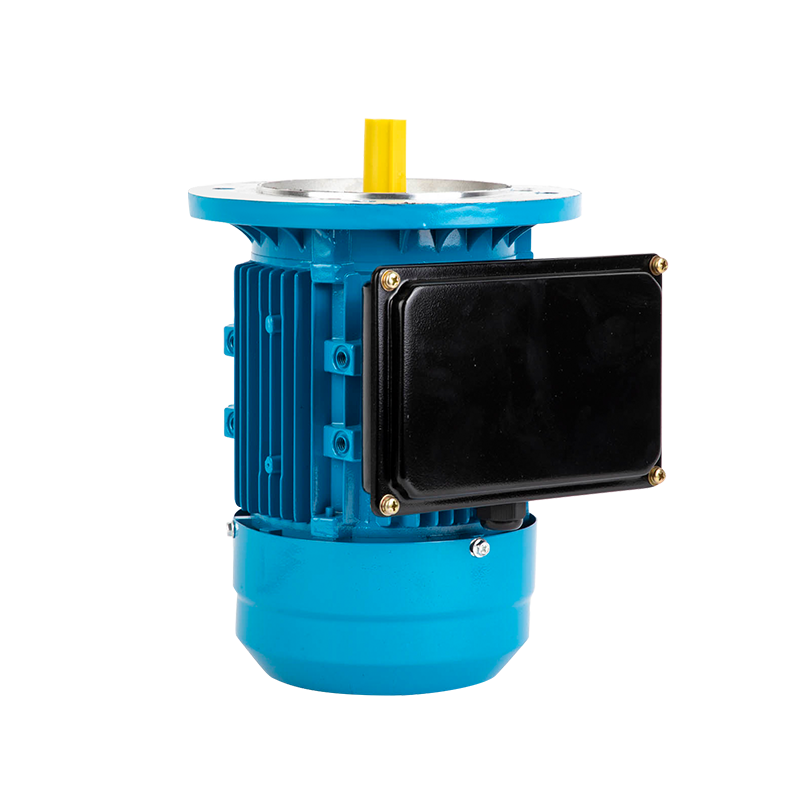

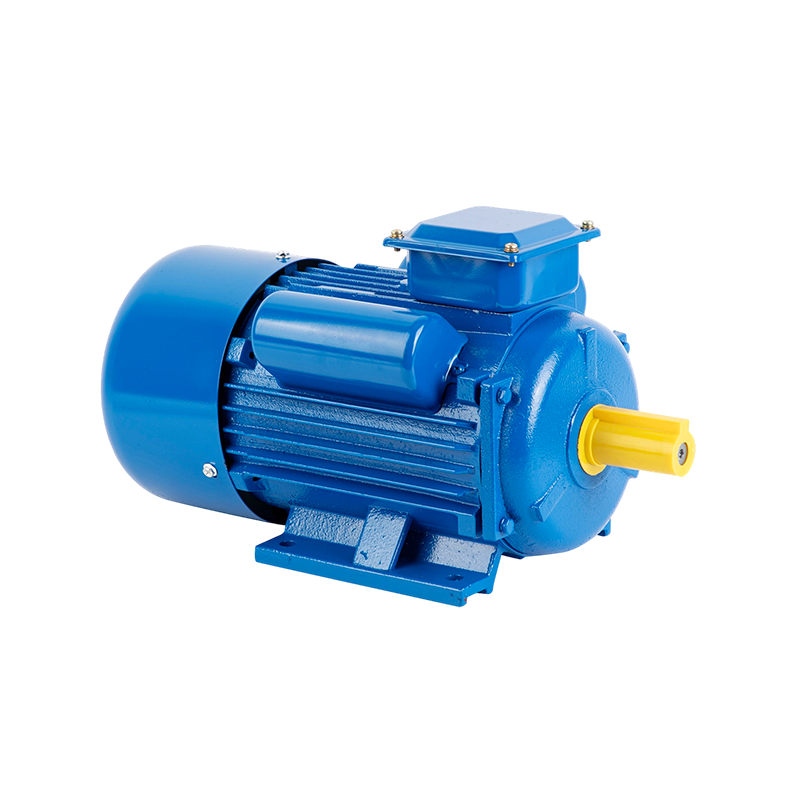

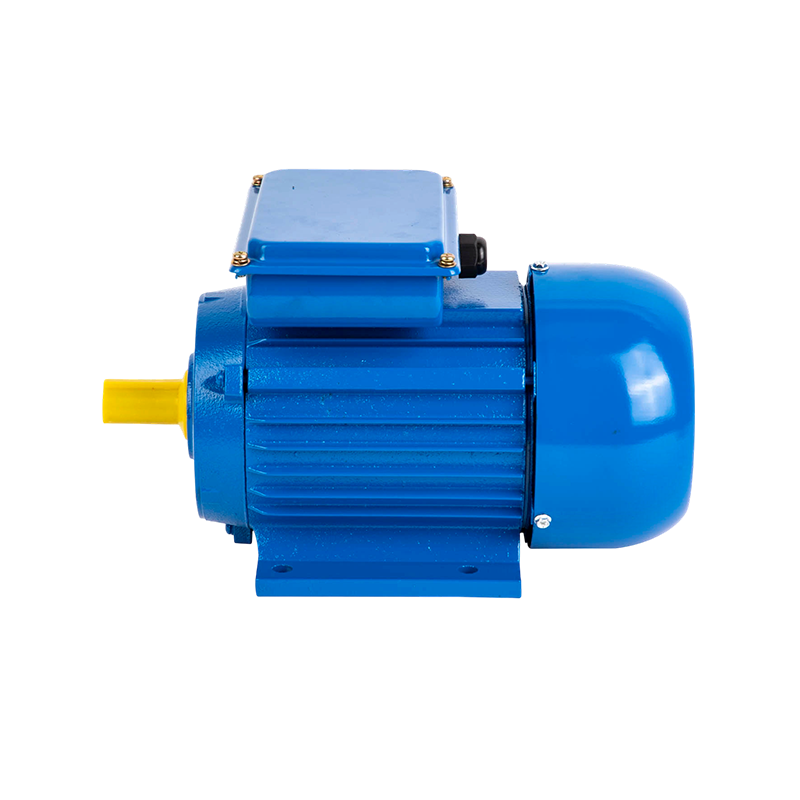

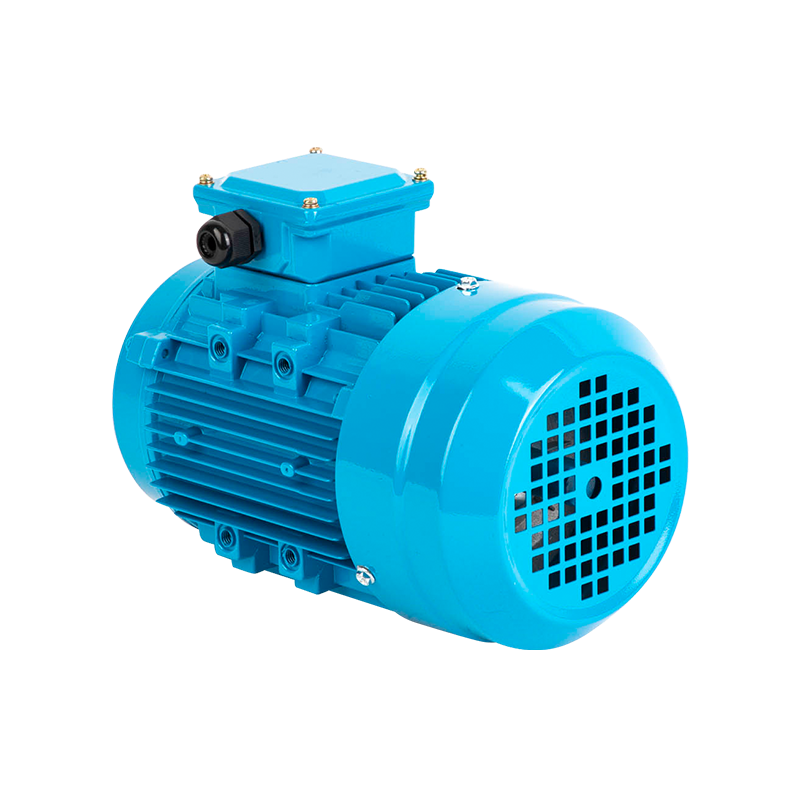

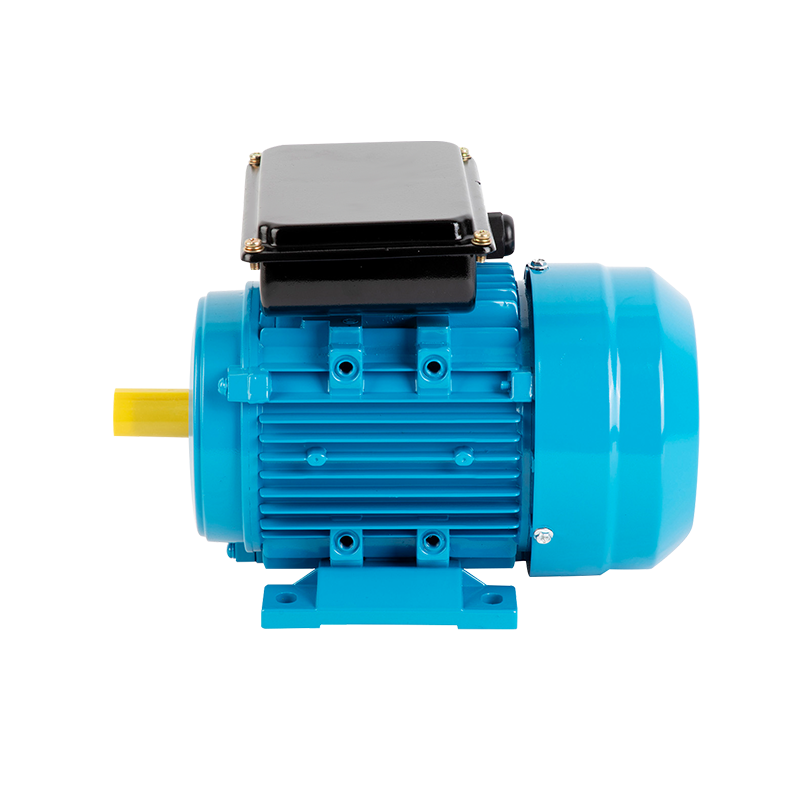

Our Heat Shrinking Machine Double Value Capacitor Asynchronous Motor is specifically engineered for heat shrinking and heat compression applications, delivering outstanding performance compared to standard single-phase motors. The double value capacitor design incorporates both a start capacitor and a run capacitor. The start capacitor generates high starting torque, allowing the motor to overcome initial resistance when the shrinking or compression process begins. The run capacitor ensures smooth, efficient operation during continuous use, maintaining consistent speed and reducing energy losses. This combination results in a motor that is reliable, energy-efficient, and durable for industrial heat shrinking operations.

2. Can this motor operate under heavy-duty industrial conditions?

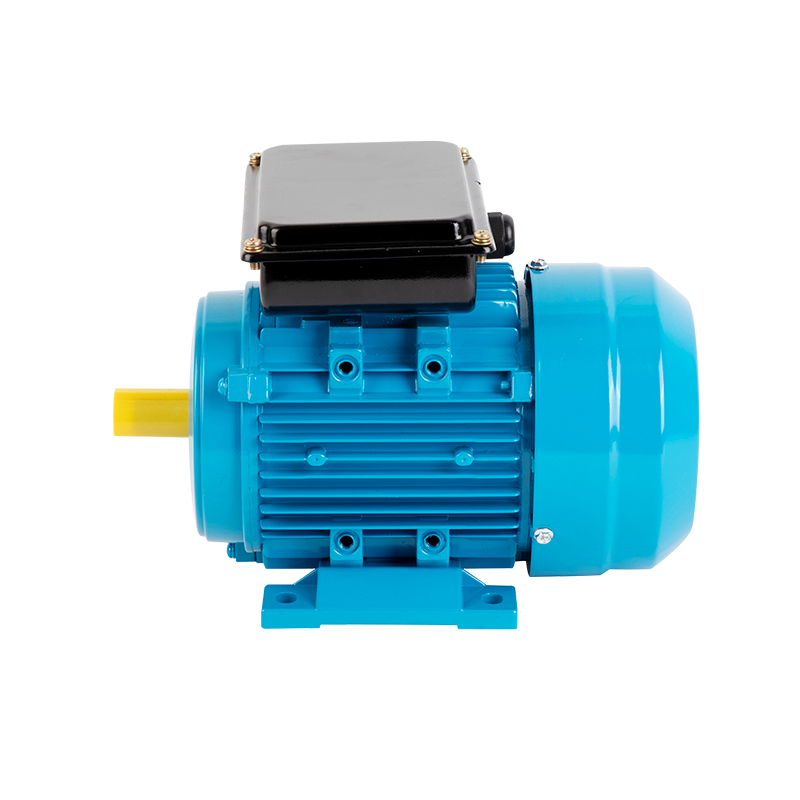

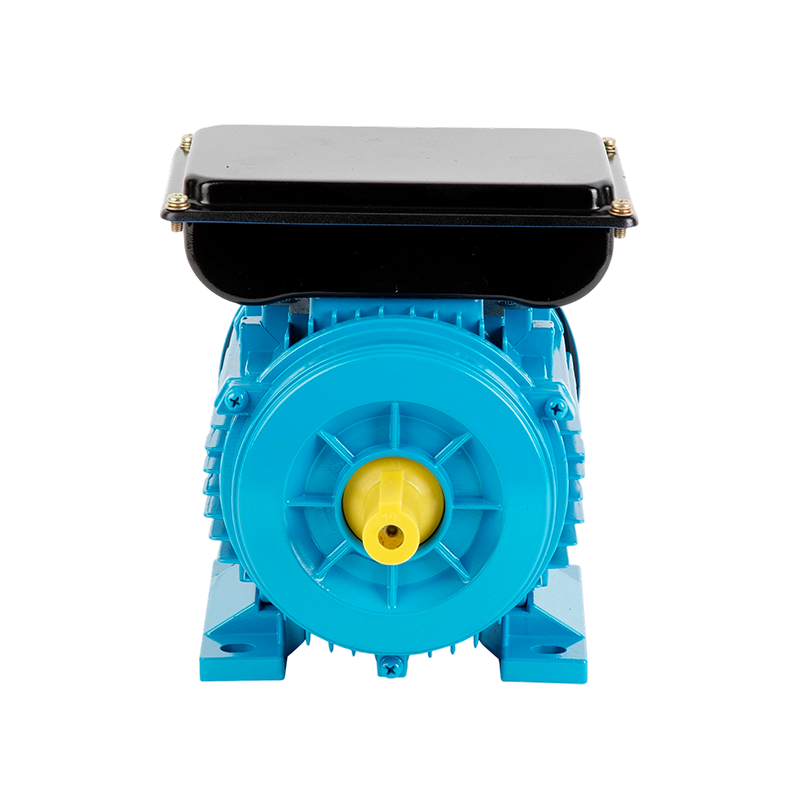

Yes. Our Heat Shrinking Machine Motor is designed to withstand demanding industrial environments. Whether you operate a heat compressor machine or a continuous heat shrinking line, this asynchronous motor can maintain high performance under prolonged workloads. Its robust construction includes high-quality windings, reinforced bearings, and a sturdy housing to resist heat, vibration, and dust. This ensures that production lines remain operational with minimal downtime and low maintenance requirements. Manufacturers who rely on consistent output find this motor ideal for both small-scale workshops and large-scale industrial applications.

3. How energy-efficient is a double value capacitor asynchronous motor?

Energy efficiency is a key advantage of our Shrinking Machine Asynchronous Motor. The double capacitor system optimizes current flow, reducing power consumption and improving power factor. This is particularly important in industrial settings where motors operate for extended periods. By maintaining stable voltage and torque, the motor minimizes energy loss and reduces operational costs. Customers who upgrade to this double capacitor asynchronous motor often notice a measurable decrease in electricity usage, while still benefiting from enhanced performance and longevity.

4. Is this motor compatible with different types of heat shrinking machines?

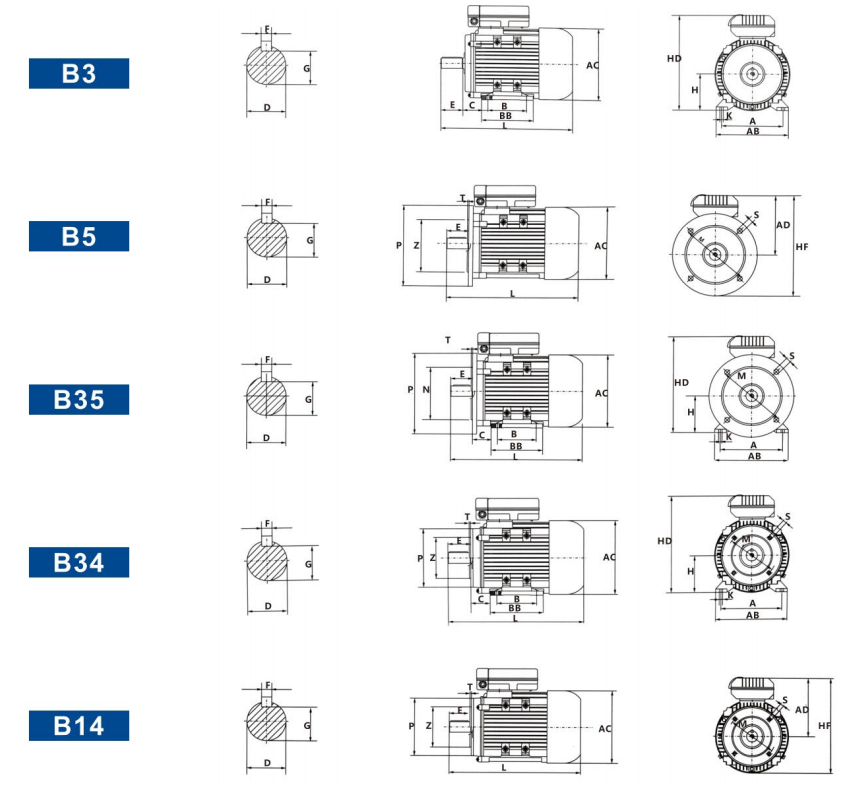

Absolutely. The Heat Shrinking Machine Motor is highly versatile and can be adapted to a wide range of heat shrinking and heat compression equipment. Our motors are available in various power ratings, shaft configurations, and mounting types, allowing easy integration into existing machinery. This flexibility makes it an ideal solution for manufacturers seeking to upgrade or replace their current motor systems without extensive modifications. We also provide technical support to ensure seamless installation and good operation for each application.

5. What maintenance is required to keep the motor running efficiently?

Maintenance for the Heat Shrinking Machine Double Value Capacitor Asynchronous Motor is straightforward, reflecting our manufacturer's focus on reliability. Regular inspections should include checking the capacitors, motor bearings, and windings for wear or overheating. Cleaning dust and debris from the motor housing and ventilation channels helps prevent heat buildup. Additionally, monitoring the motor during startup and continuous operation ensures that torque and speed remain consistent. With routine maintenance, these motors can provide years of stable performance with minimal service interruptions.

6. How does this motor enhance the performance of heat compressor machines?

When integrated into a Heat Compressor Machine Motor setup, the double value capacitor asynchronous motor provides strong starting torque and stable operation, which are critical for precise heat compression processes. Consistent speed ensures uniform heat application, which improves product quality and reduces defects. The motor's ability to maintain efficiency under heavy load conditions also extends the life of the machine, reducing repair costs and increasing overall production reliability. For manufacturers, this translates to higher productivity and lower operational risks.

7. Why should customers choose a double capacitor asynchronous motor over a single capacitor motor?

A single capacitor motor typically provides adequate performance for light-duty applications. However, for industrial heat shrinking and heat compression, the double capacitor asynchronous motor offers outstanding advantages. The start capacitor delivers high torque at startup, while the run capacitor ensures stable, efficient operation under continuous load. This combination prevents motor overheating, reduces wear, and enhances reliability. Manufacturers seeking long-term performance and low maintenance costs prefer double capacitor motors because they deliver consistent results in demanding industrial processes.