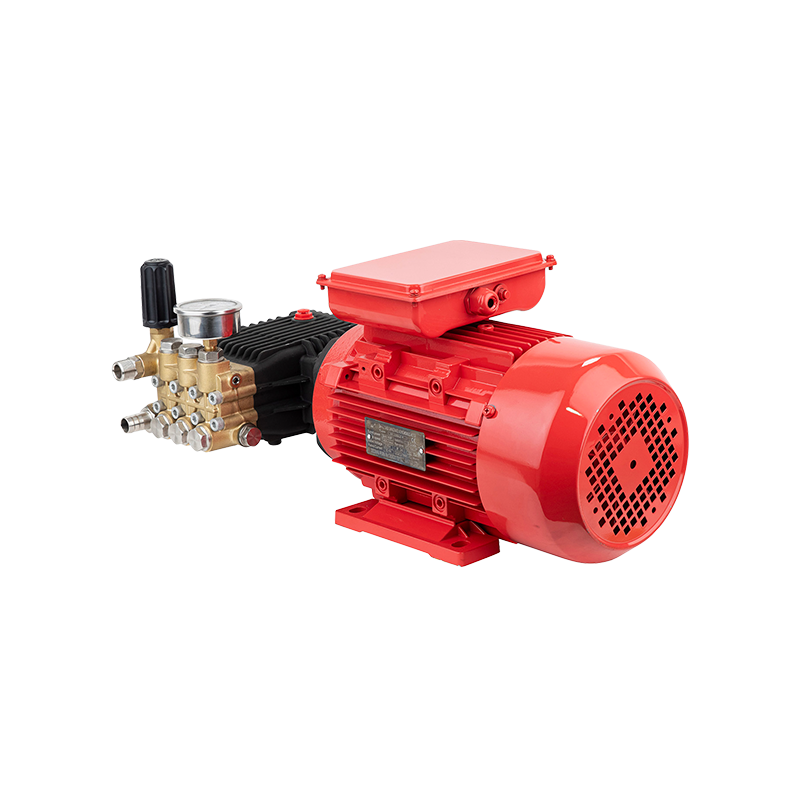

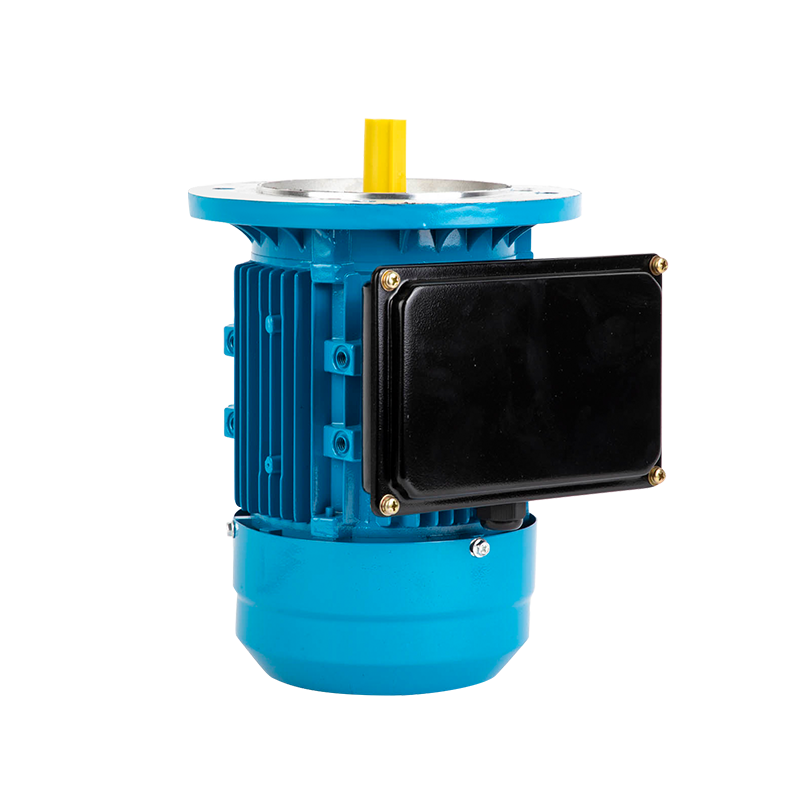

1. What is a Long Shaft Pump Motor and why is it used?

A Long Shaft Pump Motor is specifically engineered to drive pumps where the impeller or pumping mechanism is positioned at a considerable depth or distance from the motor itself. This design is common in water treatment plants, irrigation systems, and deep well applications. The extended shaft allows the motor to transmit power directly without the need for complex transmission systems.

From a manufacturer's perspective, long shaft pump motors are built with reinforced bearings, high-grade steel shafts, and precise alignment systems to ensure smooth operation even under continuous heavy loads. Buyers choose them because they reduce mechanical complexity, improve reliability, and lower long-term maintenance costs.

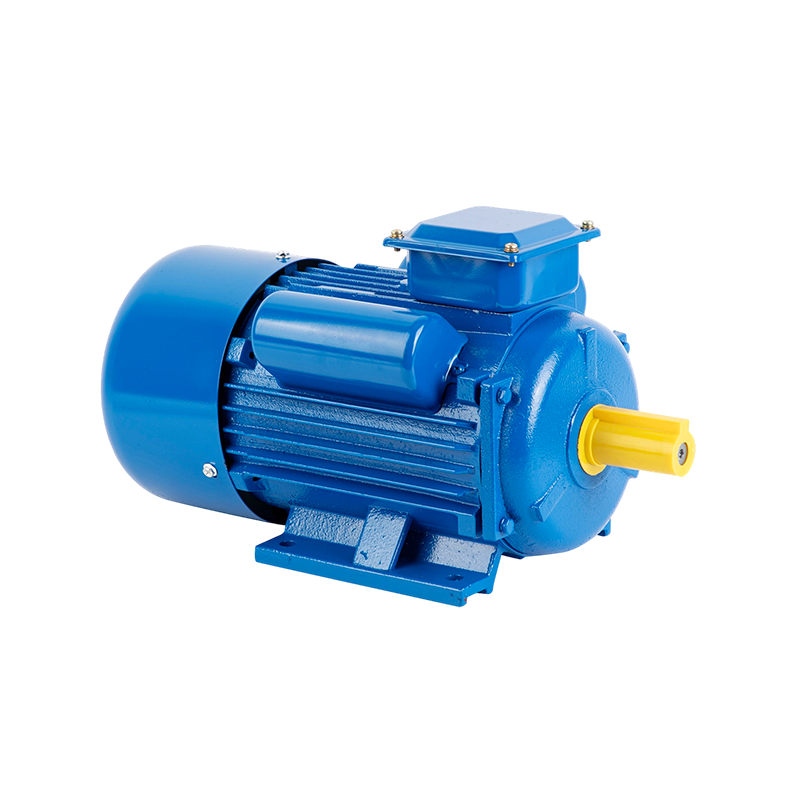

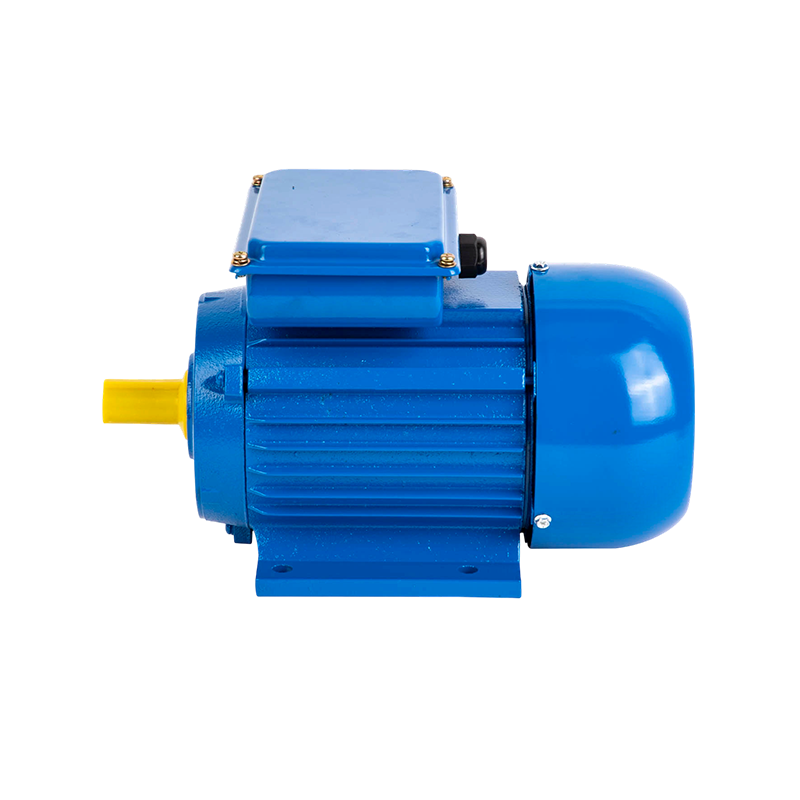

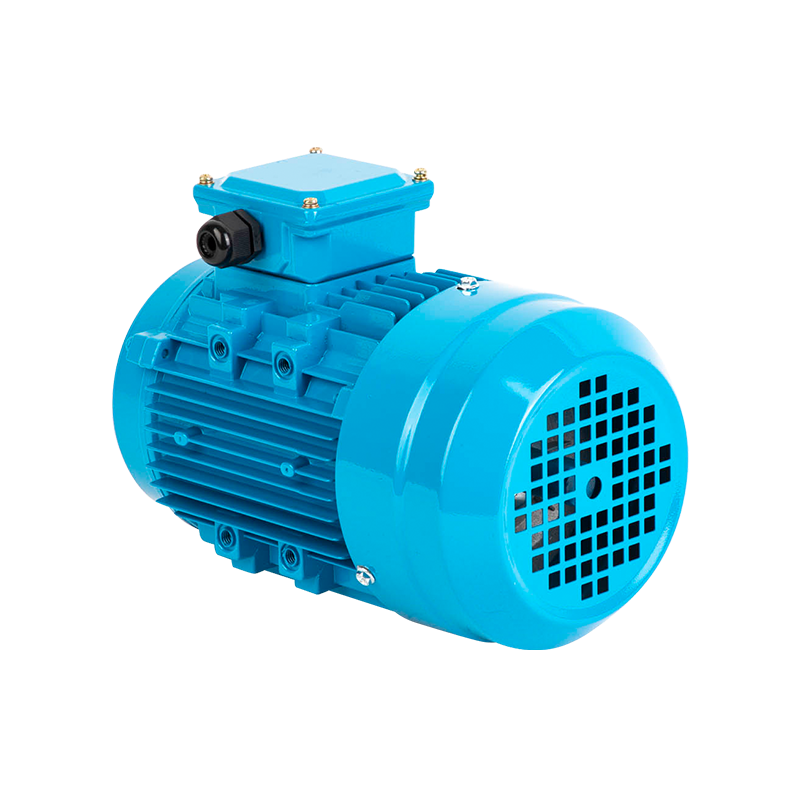

2. How does an Induction Asynchronous Motor differ from other motors?

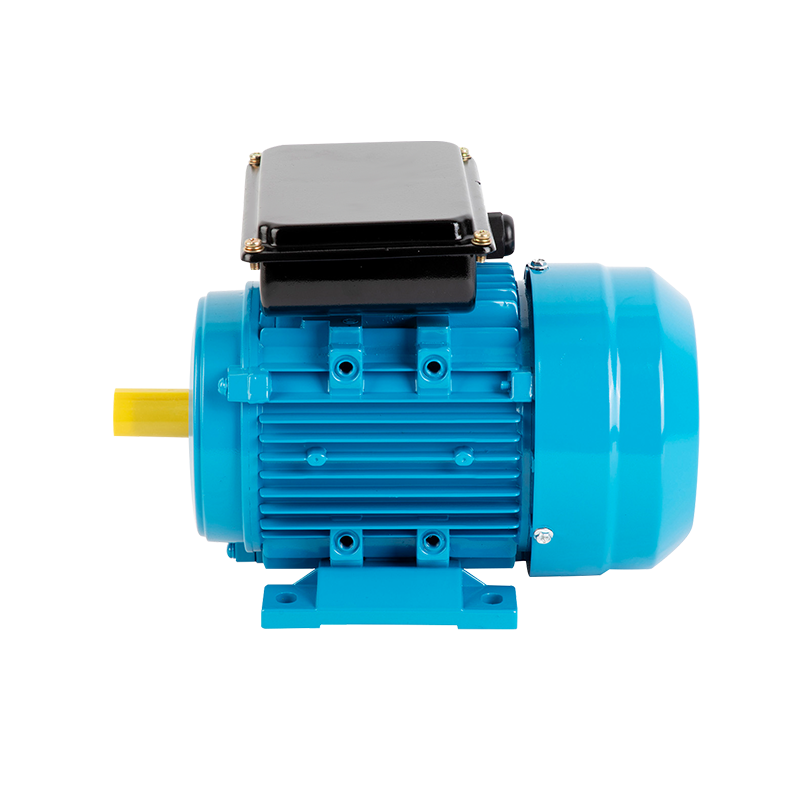

An Induction Asynchronous Motor operates on the principle of electromagnetic induction, where the rotor does not rotate at the exact synchronous speed of the stator's magnetic field. This slight difference, known as slip, enables the motor to generate torque effectively.

Compared with synchronous motors, induction asynchronous motors are simpler, more rugged, and more cost-effective. Manufacturers highlight their low maintenance needs, wide availability, and adaptability to different voltages and frequencies, making them one of widely used electric motors globally. They are often paired with long shaft designs when high reliability and stable torque output are required in pumping or conveyor systems.

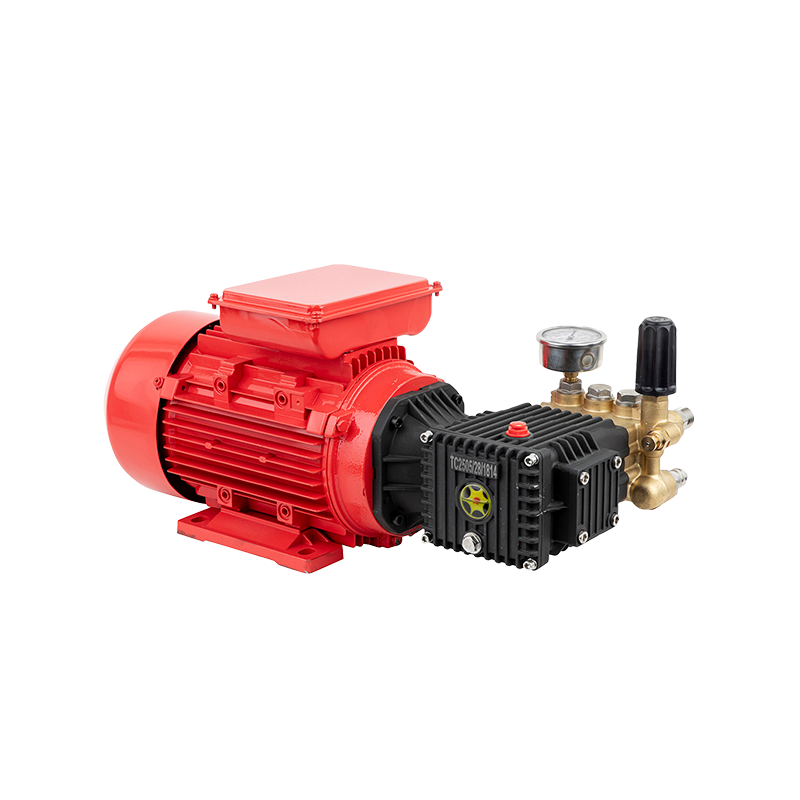

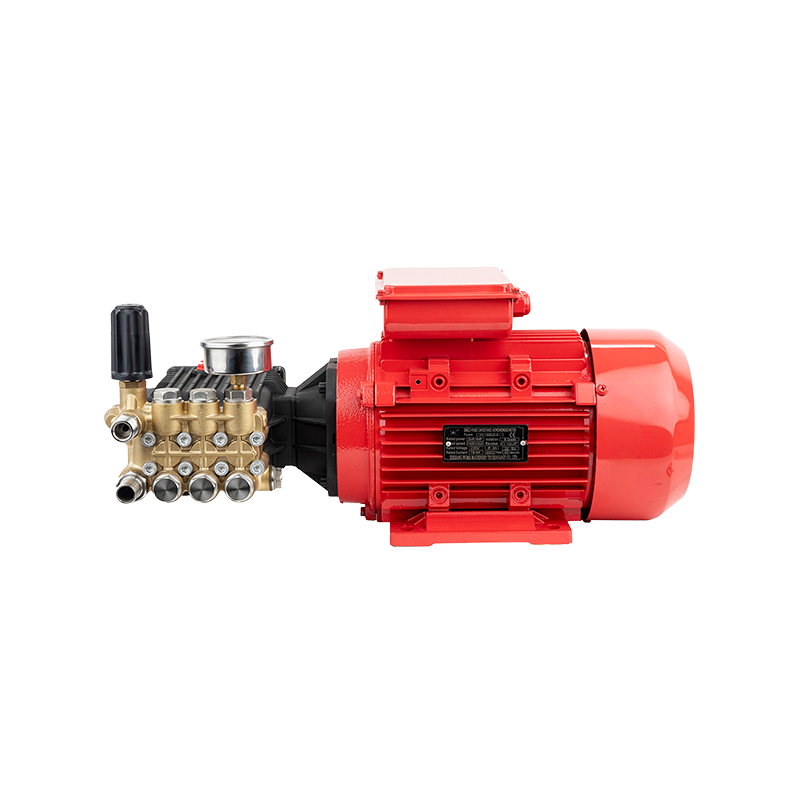

3. What advantages does an Electric Motor With Long Shaft provide?

An Electric Motor With Long Shaft offers unique structural and functional benefits. Instead of requiring couplings or additional transmission parts, the extended shaft directly connects to the driven equipment, minimizing alignment issues.

For industries such as chemical processing, agriculture, mining, and municipal water supply, this translates to:

- Reduced vibration due to fewer moving parts.

- Compact system design, saving space in crowded installations.

- Higher efficiency, since energy is not lost in extra mechanical connections.

From the manufacturer's angle, offering electric motors with long shafts demonstrates flexibility in custom design. Many buyers request specific shaft lengths, special coatings for corrosion resistance, or unique mounting arrangements, and experienced suppliers can meet these requirements efficiently.

4. Why are Long Shaft Pump Motors important for water management systems?

In municipal and agricultural sectors, pumping systems often require motors that can operate deep wells or sub-surface pumps. A Long Shaft Pump Motor ensures continuous and reliable water lifting, even under fluctuating load conditions.

Manufacturers stress the importance of sturdy construction, moisture protection, and thermal resistance in these motors to ensure long life. Procurement managers in water utilities or irrigation projects often prioritize suppliers that can provide bulk, high-reliability motors with warranty support, ensuring uninterrupted operation during peak demand seasons.

5. What should buyers consider when sourcing Induction Asynchronous Motors?

Buyers evaluating induction asynchronous motors should look at:

- Efficiency class (IE2, IE3, or IE4) to meet regulatory and cost-saving goals.

- Voltage and frequency compatibility with local power supply standards.

- Durability of materials (copper windings, silicon steel laminations, and heat-resistant insulation).

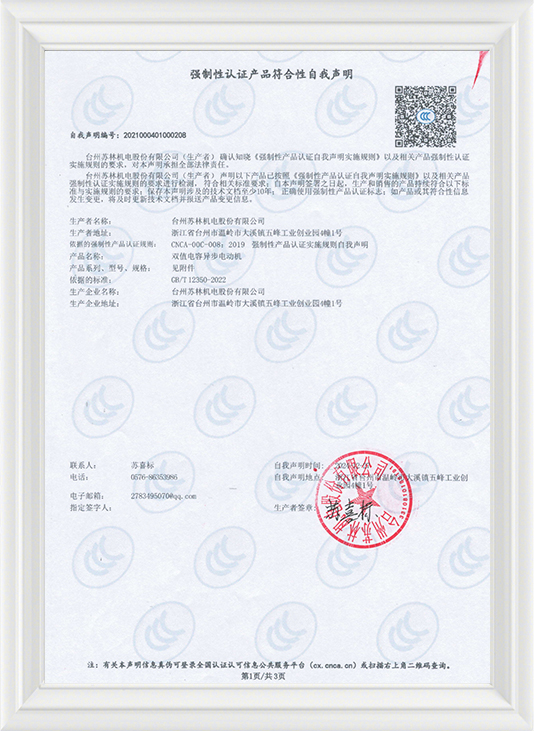

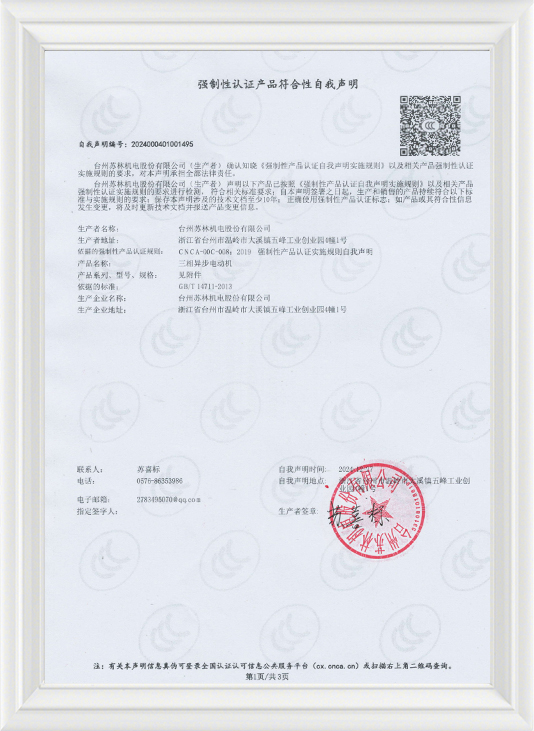

- Manufacturer certifications like ISO, CE, or UL for quality assurance.

For procurement at scale, long-term reliability and after-sales support are just as important as price. professional manufacturers provide OEM/ODM services, spare parts availability, and technical training, which are key advantages for buyers managing large industrial fleets of motors.

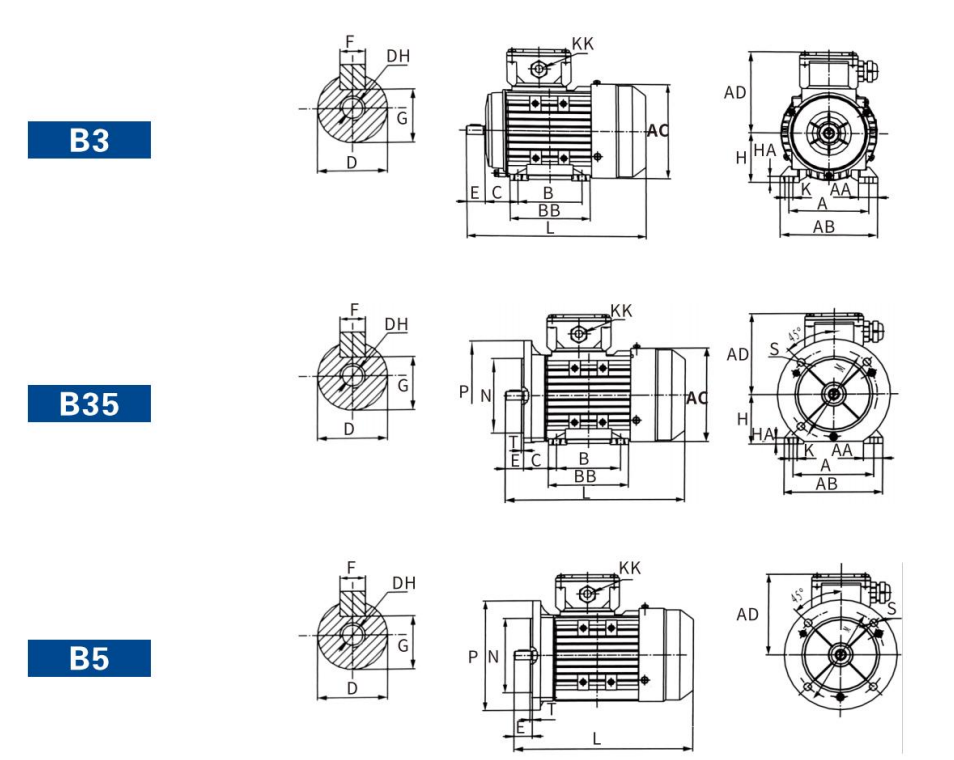

6. Can Electric Motors With Long Shafts be customized?

Yes. One of the main advantages manufacturers highlight is the ability to customize shaft length, motor frame size, mounting options, and protective enclosures to fit specific applications. For example, a buyer in the petrochemical sector may require explosion-proof enclosures, while an agricultural buyer may prioritize moisture-resistant coatings.

This adaptability makes the electric motor with long shaft highly appealing for wholesale buyers seeking tailored solutions for diverse industries.

Manufacturers provide competitive advantages through customization, high-quality materials, and global support, making these motors reliable investments for procurement managers. By focusing on both technical performance and tailored solutions, these motors continue to be in high demand across industries such as water management, agriculture, mining, and manufacturing.