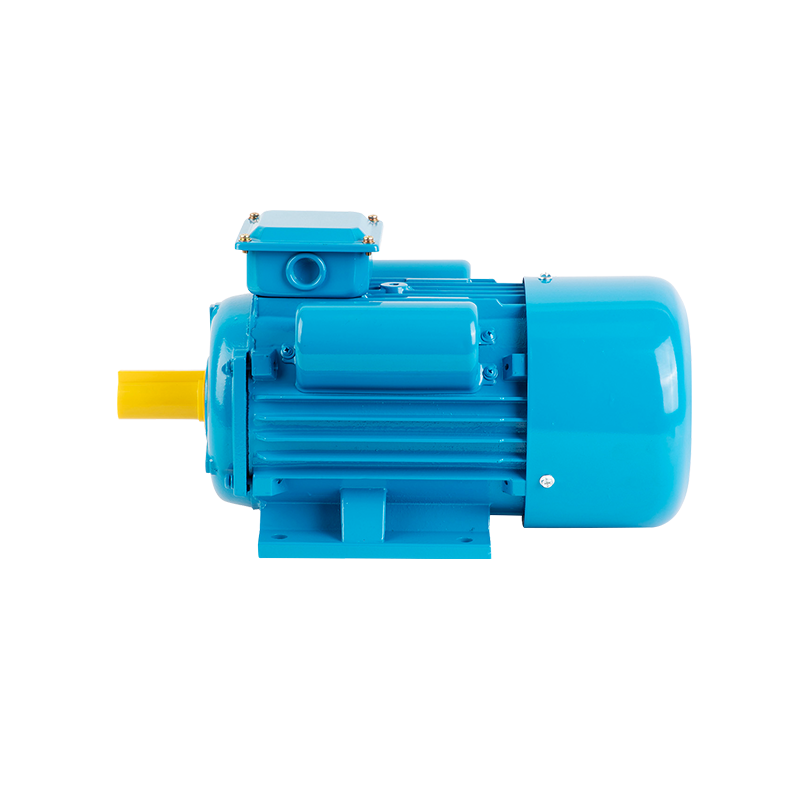

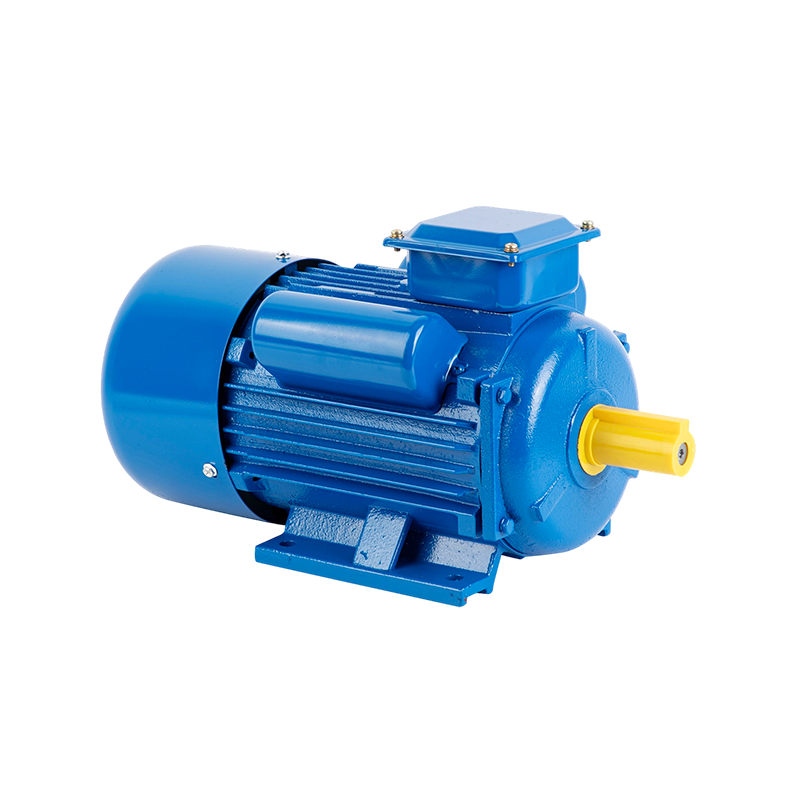

Overview of Industrial Grinder Motors

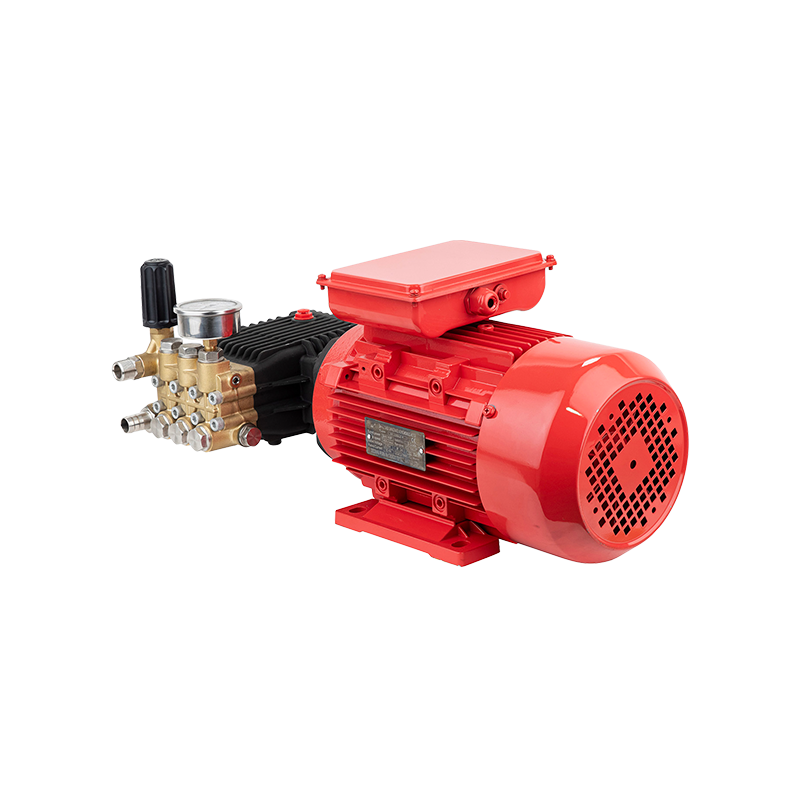

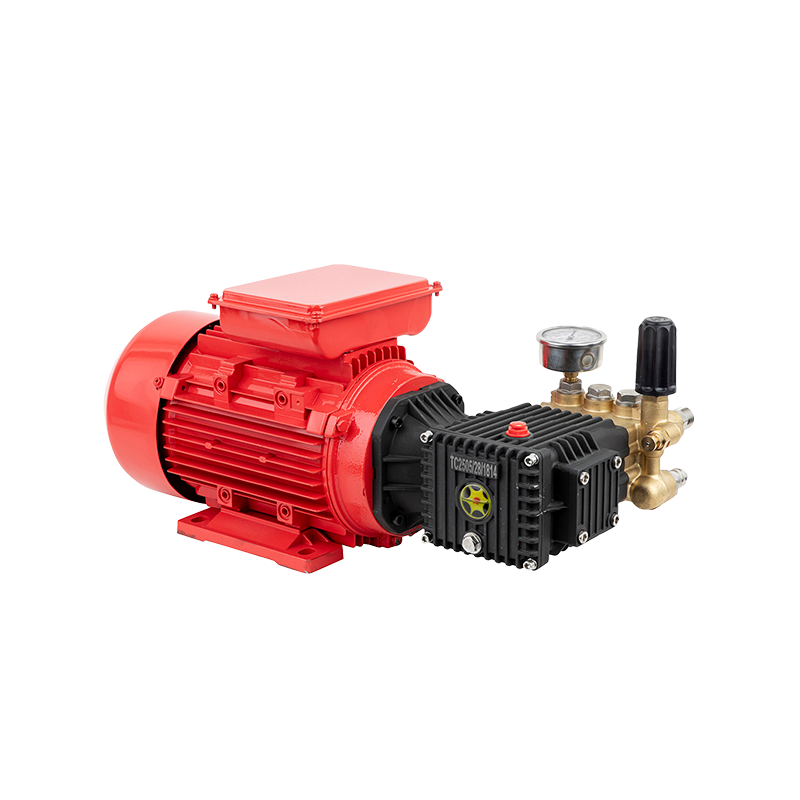

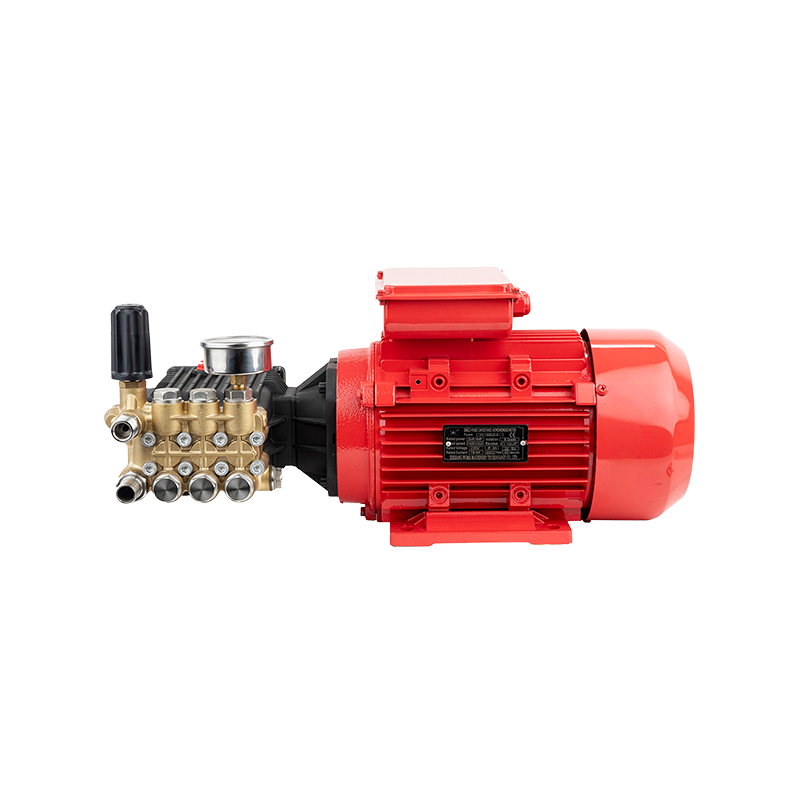

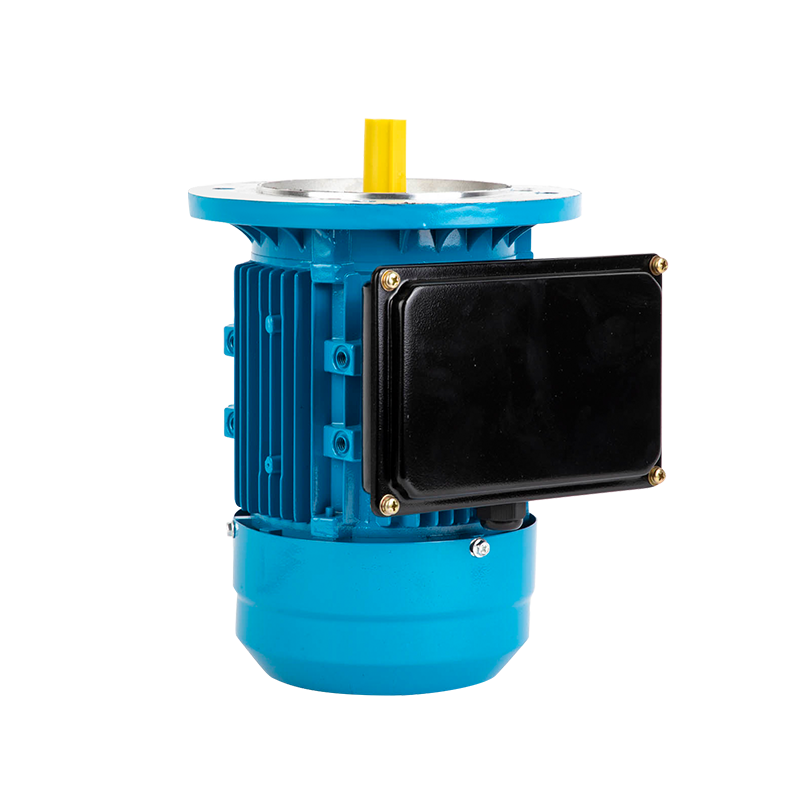

Industrial grinder motors are a critical component in modern manufacturing and processing facilities. Designed to deliver consistent power, reliability, and durability, these motors are specifically engineered to drive heavy-duty grinders used in metal, wood, and plastic processing. The industrial grinder motor provides the necessary torque and speed to handle continuous operation while minimizing downtime, ensuring that production lines remain efficient and productive. Manufacturers increasingly rely on these motors to enhance the performance of grinding equipment, reduce maintenance costs, and extend operational life.

The Role of Double Capacitor Motors

A double capacitor motor, also known as a dual capacitor motor, incorporates two capacitors – a start capacitor and a run capacitor – to optimize motor performance. The start capacitor provides a high starting torque, allowing the grinder motor to overcome initial load resistance. Meanwhile, the run capacitor maintains efficient operation at continuous speeds, reducing energy consumption and stabilizing torque output. For applications like industrial grinders, where frequent starts and stops are required, the double capacitor motor design ensures smooth operation and protects the motor from overheating or excessive wear.

Advantages of Grinder Motor Capacitors

The grinder motor capacitor plays a vital role in controlling current and voltage for good motor function. By storing and releasing energy efficiently, the capacitor improves motor efficiency, prevents voltage drops, and supports high starting torque. This results in a more reliable grinder operation, especially in environments with fluctuating power supply. Capacitors also contribute to noise reduction and vibration control, improving the overall working environment and extending the lifespan of the grinder motor.

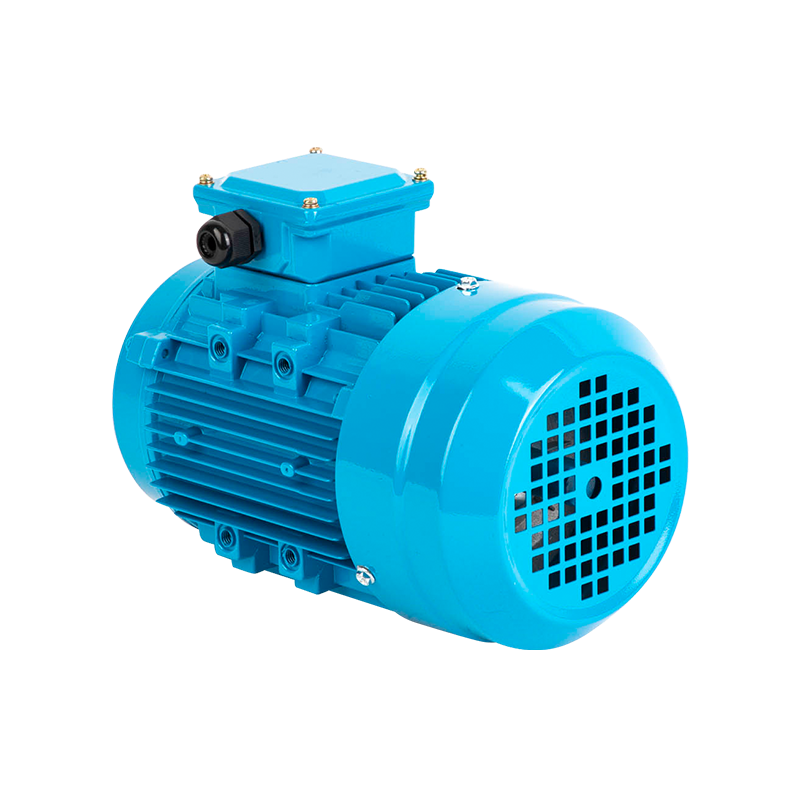

Applications in Industrial Settings

Industrial grinder motors with double capacitors are widely applied across multiple industries. In metalworking, these motors power bench grinders, surface grinders, and cylindrical grinders. In wood and plastic industries, they are used in high-speed grinders for shaping, sanding, and finishing operations. The combination of high torque and stable speed makes these motors ideal for precision grinding tasks that require consistent quality. Additionally, their robust construction allows them to operate in demanding environments, including workshops with high dust levels, heat, and vibration.

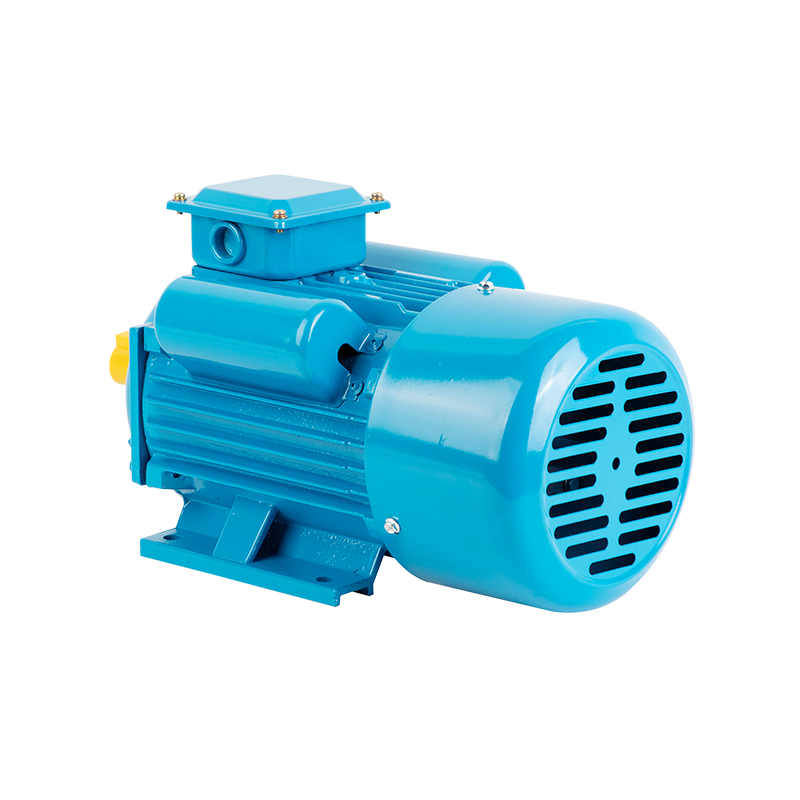

Energy Efficiency and Performance

One of the standout features of industrial grinder motors equipped with dual capacitors is their energy efficiency. Compared to standard single-phase motors, the double capacitor design reduces energy losses and enhances power factor, translating into lower electricity costs. By maintaining good current flow during operation, these motors also reduce mechanical stress on the grinder components, lowering maintenance requirements and increasing service life. The result is a motor that not only performs reliably but also contributes to sustainable production practices.

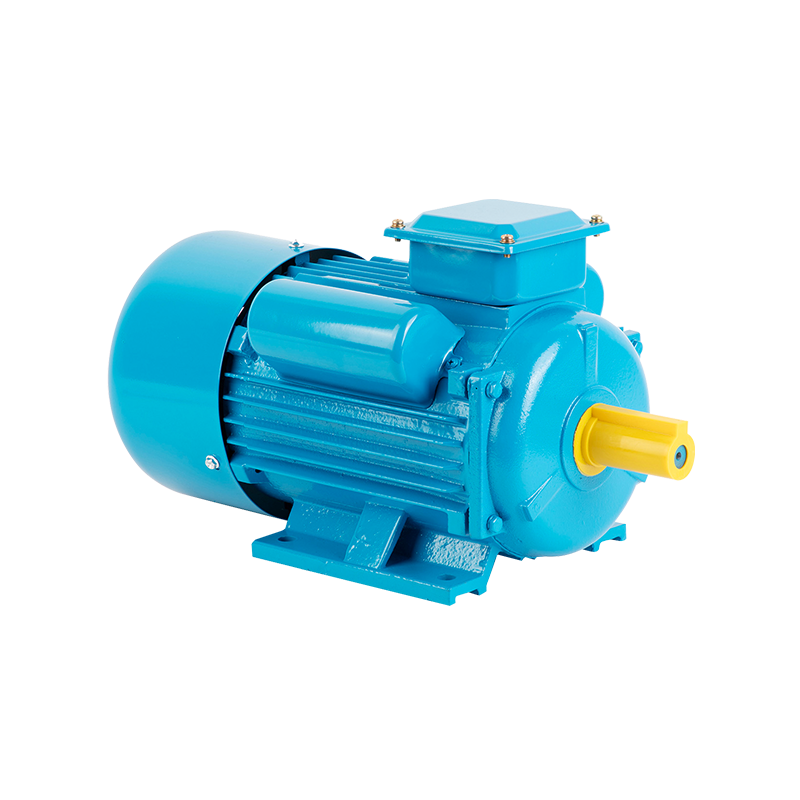

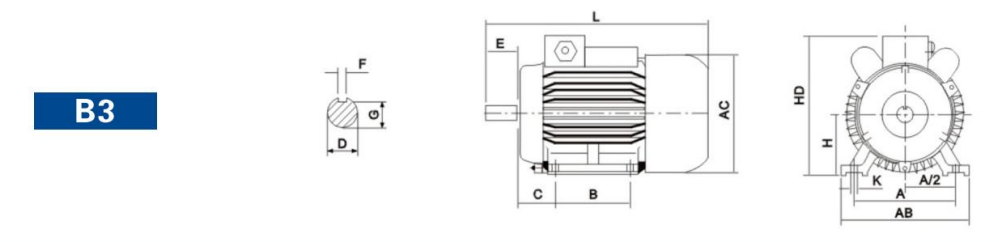

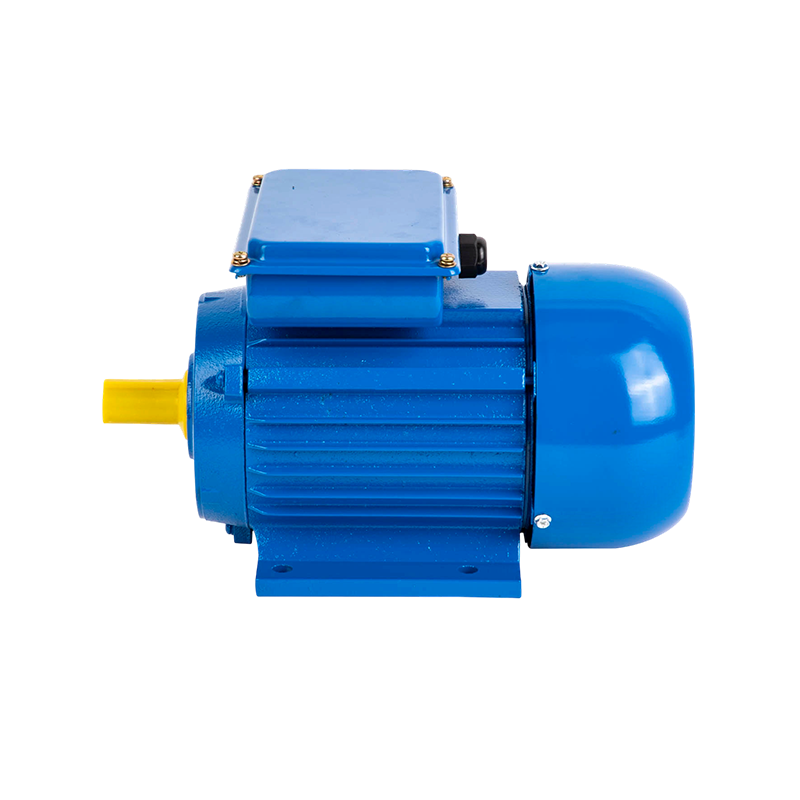

Customization and Manufacturer Advantages

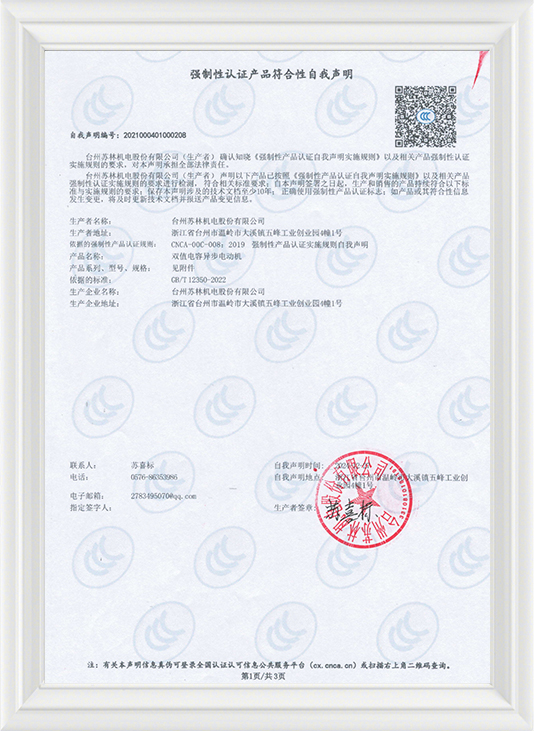

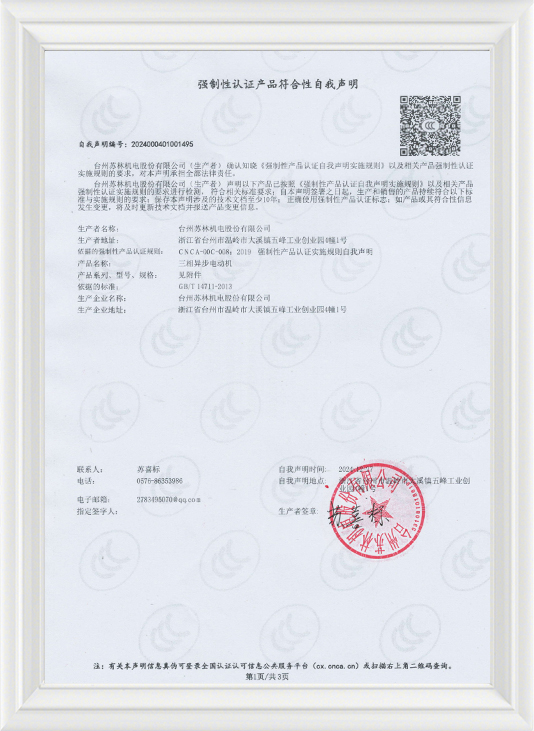

professional manufacturers offer customization options for grinder motors, including variable shaft lengths, mounting configurations, and power ratings. This allows businesses to select a motor tailored to their specific grinding equipment and operational demands. From a manufacturer's perspective, producing high-quality double capacitor motors requires advanced engineering, precision assembly, and rigorous quality control. These capabilities enable the production of motors that consistently meet performance standards while providing long-term reliability to industrial customers.

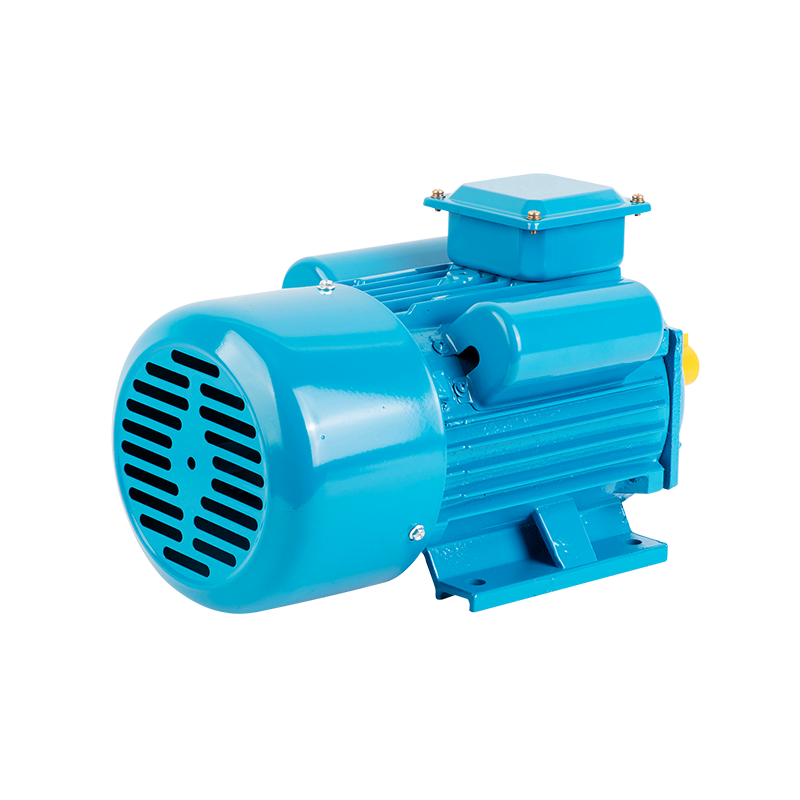

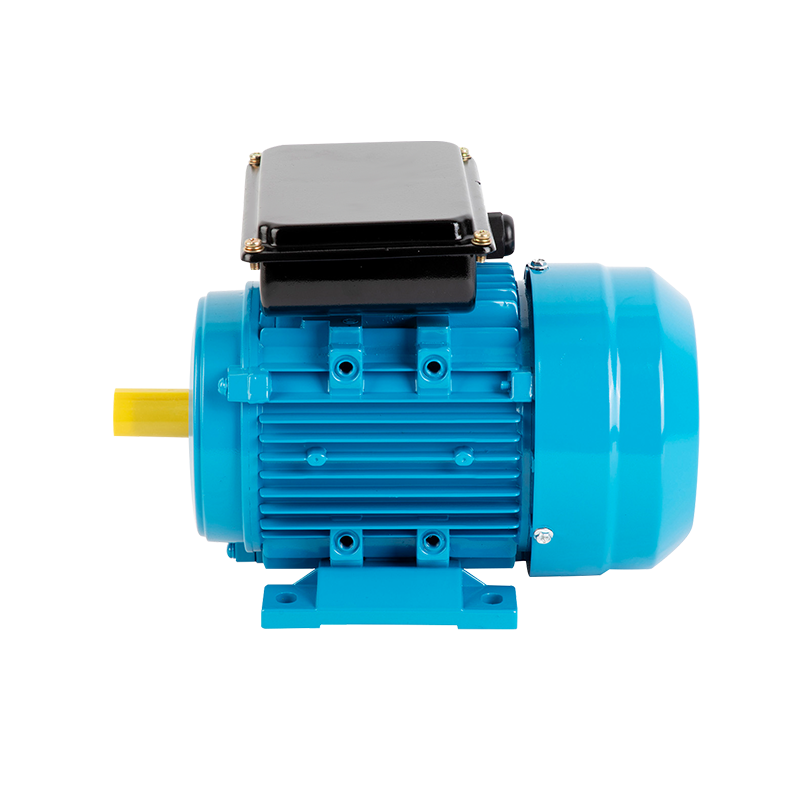

Maintenance and Longevity

Proper maintenance of grinder motors with capacitors ensures long-term performance and reduces the risk of unexpected downtime. Regular inspection of capacitors, motor windings, and bearings can prevent common issues such as overheating, electrical faults, and mechanical wear. Industrial motors with high-quality components are designed to withstand prolonged operational cycles, making them a cost-effective solution for businesses that rely on continuous grinding operations. Manufacturers emphasize the durability and robustness of their motors, ensuring that customers receive a product that supports years of reliable service.