Automation Equipment Motor: Driving Modern Manufacturing

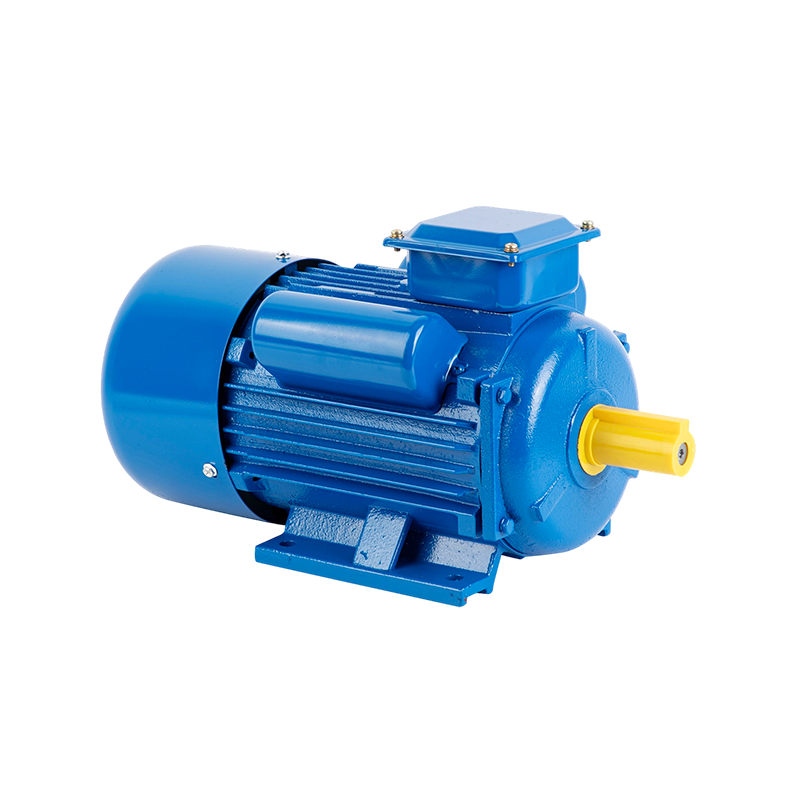

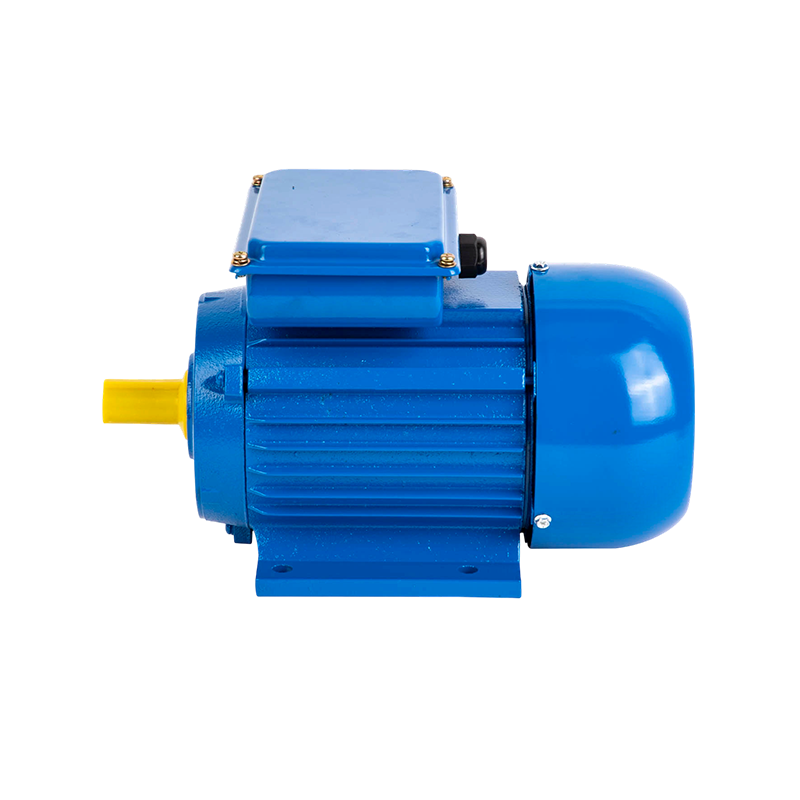

In today's rapidly evolving production landscape, the Automation Equipment Motor has become a cornerstone of efficiency and reliability. These motors are specially designed to power automated systems such as robotic arms, conveyors, packaging machines, and CNC equipment. Unlike conventional motors, automation equipment motors are engineered with high precision, consistent torque output, and low vibration characteristics, ensuring smooth operation in sensitive production environments.

From a manufacturer's perspective, producing motors for automation equipment requires strict quality control and advanced production lines. By utilizing CNC machining, precision winding technologies, and automated testing systems, manufacturers guarantee motors that deliver accuracy and long service life. For buyers, this translates into reduced downtime, higher production throughput, and lower total cost of ownership.

Automation Control Motor: Precision and Adaptability

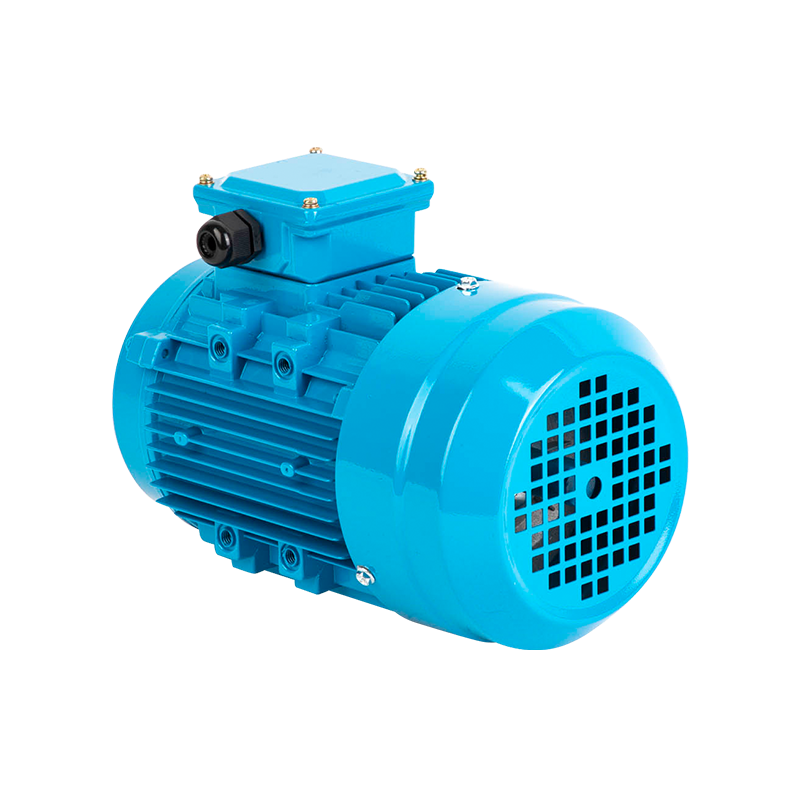

The Automation Control Motor plays a critical role in systems that require constant adjustment and responsive feedback. Paired with controllers, sensors, and variable frequency drives, these motors allow precise speed regulation, torque control, and synchronization with other equipment. They are widely applied in packaging machinery, textile production, printing systems, and assembly lines, where even small deviations can impact quality and efficiency.

From the manufacturing side, the advantage lies in flexible product design. Suppliers often offer a range of motor types—AC, DC, servo, and stepper—adapted for automation control tasks. The emphasis is on high-efficiency windings, advanced insulation, and compatibility with intelligent controllers. By delivering motors that can easily integrate with programmable logic controllers (PLCs) and industrial IoT platforms, manufacturers provide future-ready solutions that align with the ongoing shift toward smart factories.

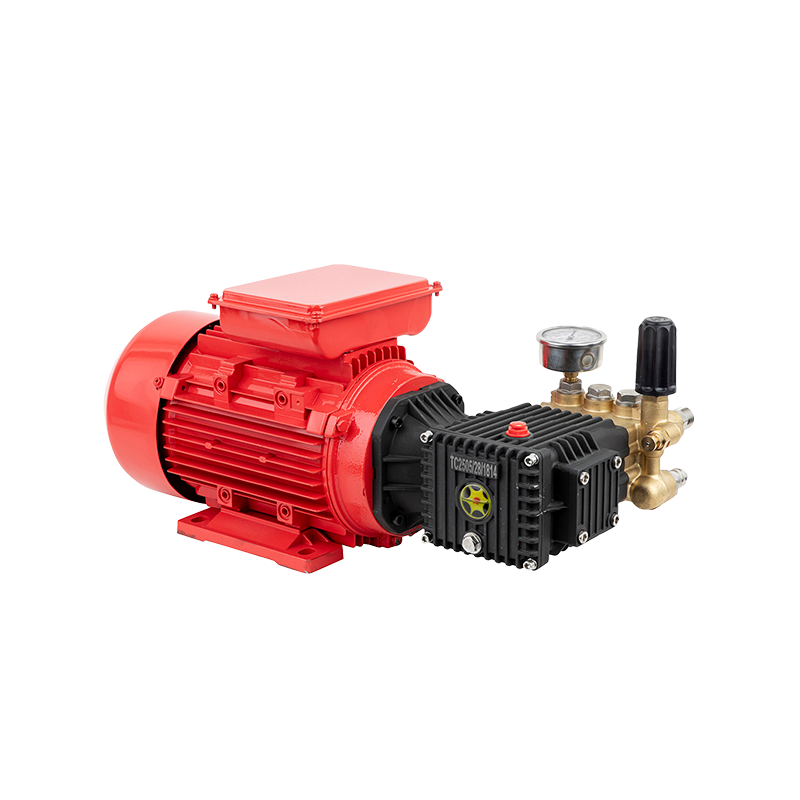

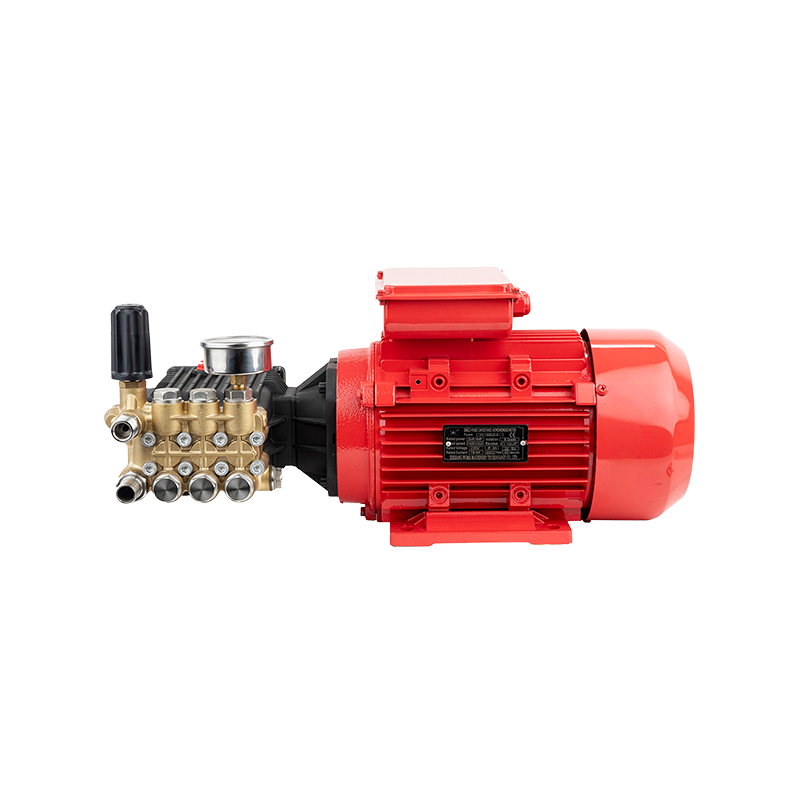

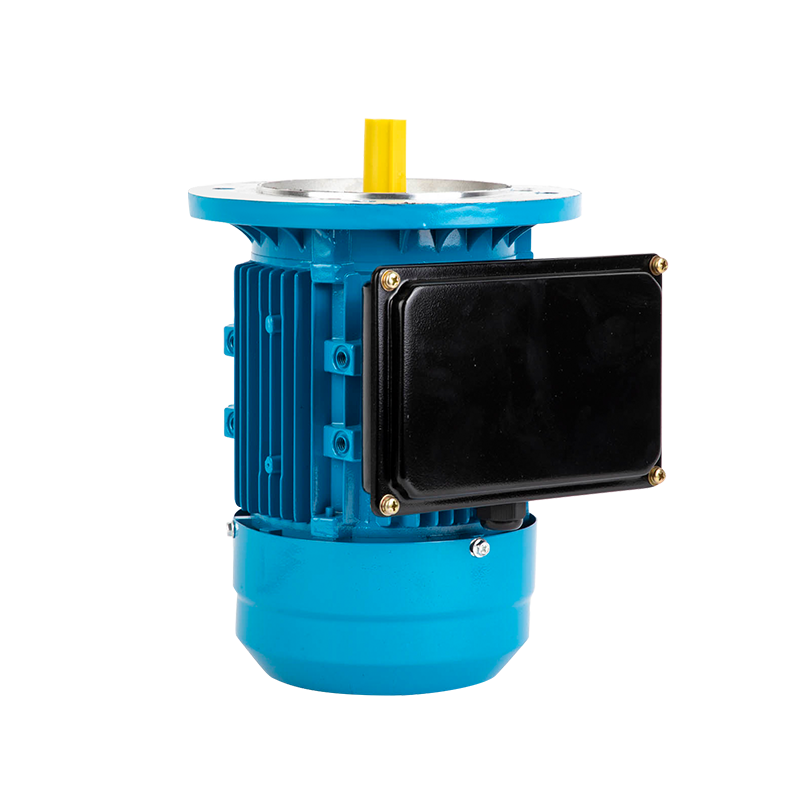

Asynchronous Motor Drive: Reliability at Scale

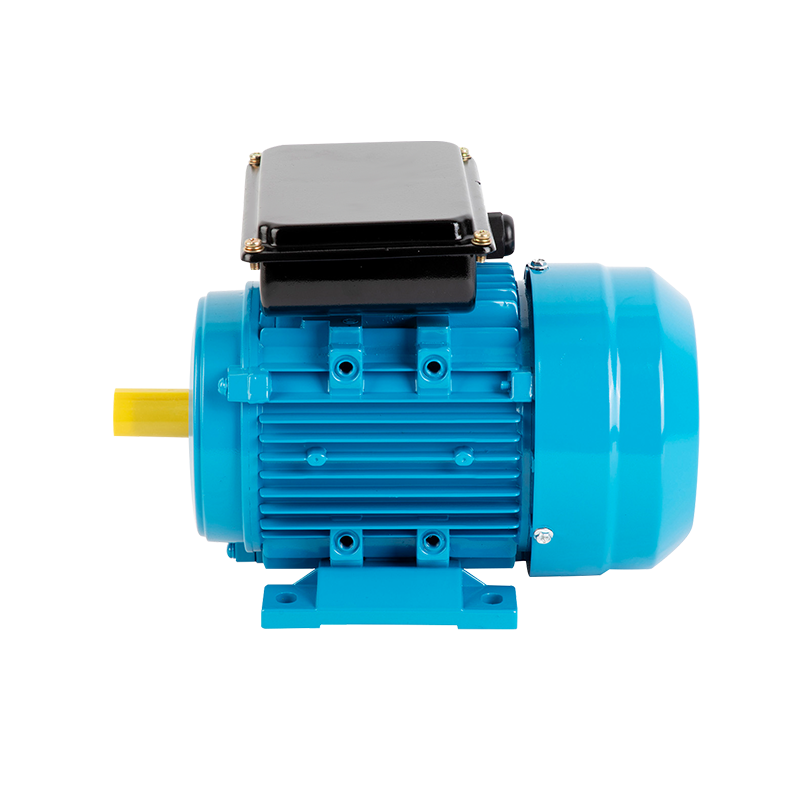

The Asynchronous Motor Drive, commonly known as the induction motor system, remains widely adopted drive solution across global industries. It offers an ideal balance between performance and affordability. These drives are valued for their rugged construction, low maintenance requirements, and adaptability to different voltage and frequency standards.

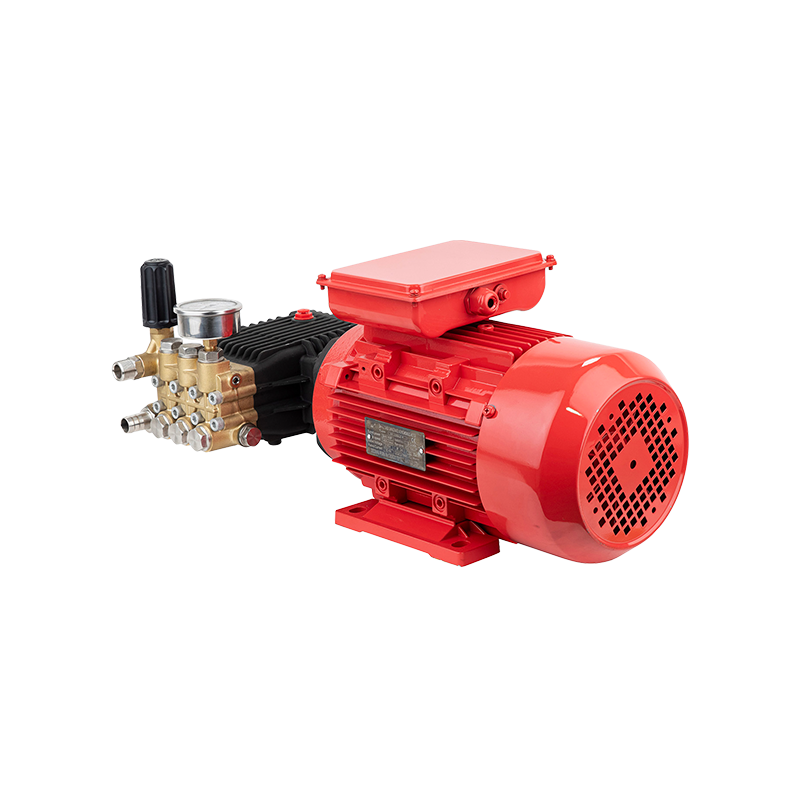

When combined with automation systems, the asynchronous motor drive delivers stable torque and efficient energy usage, even under fluctuating loads. This makes them particularly suitable for fans, pumps, conveyors, compressors, and other continuous-duty applications.

Manufacturers highlight their strength in producing high-efficiency asynchronous motor drives (IE2, IE3, and IE4 efficiency classes) that meet international energy regulations. By investing in advanced winding machines, vacuum pressure impregnation for insulation, and automated balancing systems, they ensure each motor drive achieves outstanding reliability and reduced energy consumption.

Manufacturer's Production Advantages

When presenting Automation Equipment Motors, Automation Control Motors, and Asynchronous Motor Drives, professional manufacturers emphasize their competitive edge:

- Advanced Manufacturing Technology – Modern facilities are equipped with CNC centers, robotic winding stations, and automatic testing rigs to guarantee precision in every stage of production.

- Material advanced – High-grade silicon steel, copper windings, and heat-resistant insulation ensure motors can withstand demanding operating conditions.

- Energy Efficiency Compliance – Motors are designed in line with IE3/IE4 international efficiency standards, helping buyers achieve lower energy costs and sustainability goals.

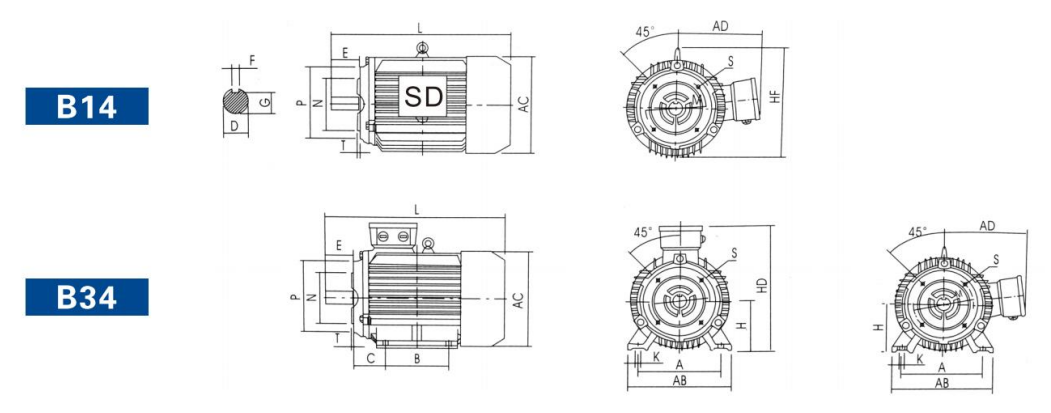

- Customization Services – OEM and ODM options allow shaft dimensions, mounting types, enclosures, and voltage ratings to be tailored to specific applications.

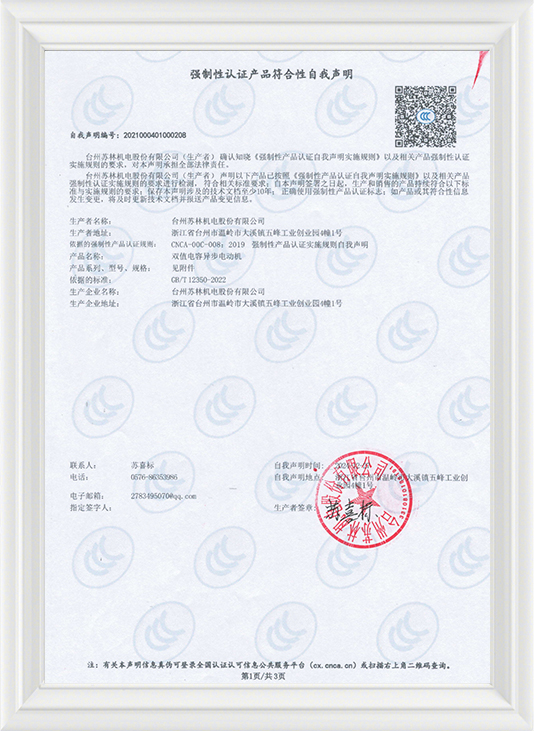

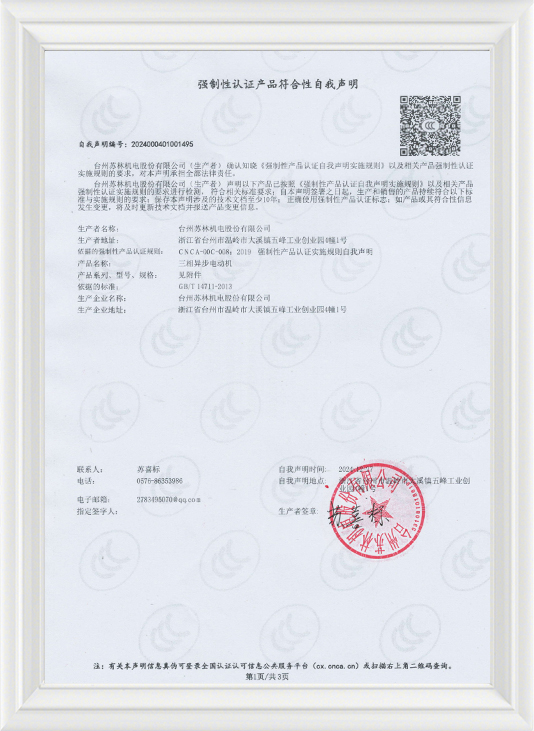

- Global Standards – Motors carry certifications such as CE, ISO, or UL, ensuring international buyers can deploy them confidently.

- After-Sales Support – Dedicated technical teams, spare parts availability, and training programs enhance long-term buyer confidence.

Applications Across Industries

- Manufacturing Automation – robotic arms, CNC machines, and packaging systems.

- Textiles and Printing – precise speed and torque control for fabric processing and printing quality.

- HVAC and Pumps – asynchronous motor drives powering compressors, fans, and circulation systems.

- Logistics – conveyor and sorting systems for warehouses and e-commerce facilities.

By integrating automation equipment motors and automation control motors with asynchronous motor drives, manufacturers help industries achieve higher productivity, reduced waste, and smarter energy usage.

The combination of Automation Equipment Motor, Automation Control Motor, and Asynchronous Motor Drive reflects the growing demand for efficiency, precision, and adaptability in modern industries. From water pumps and conveyors to robotics and smart factories, these motors serve as the backbone of automation.