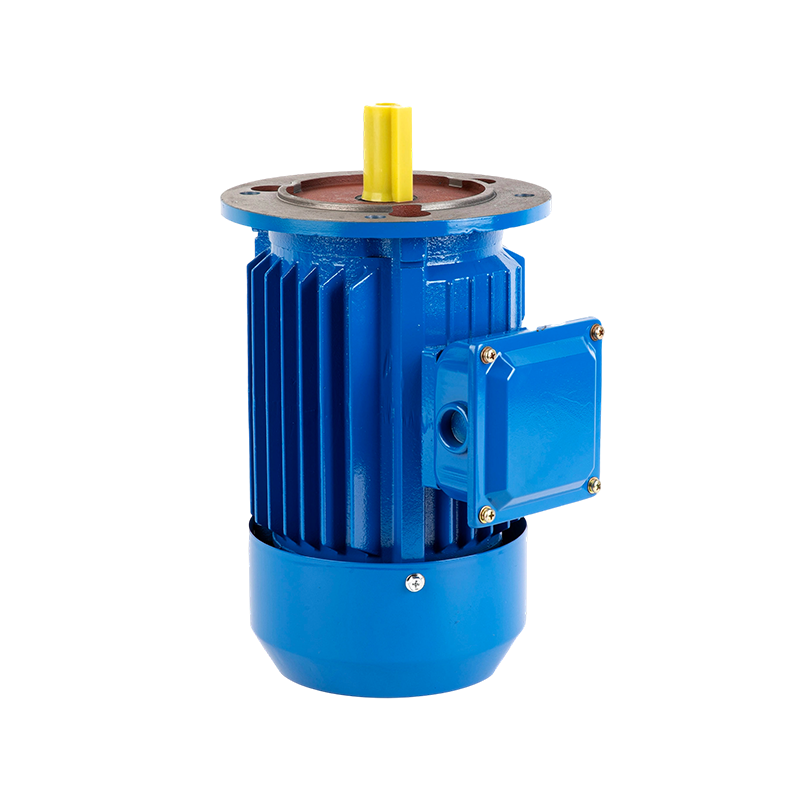

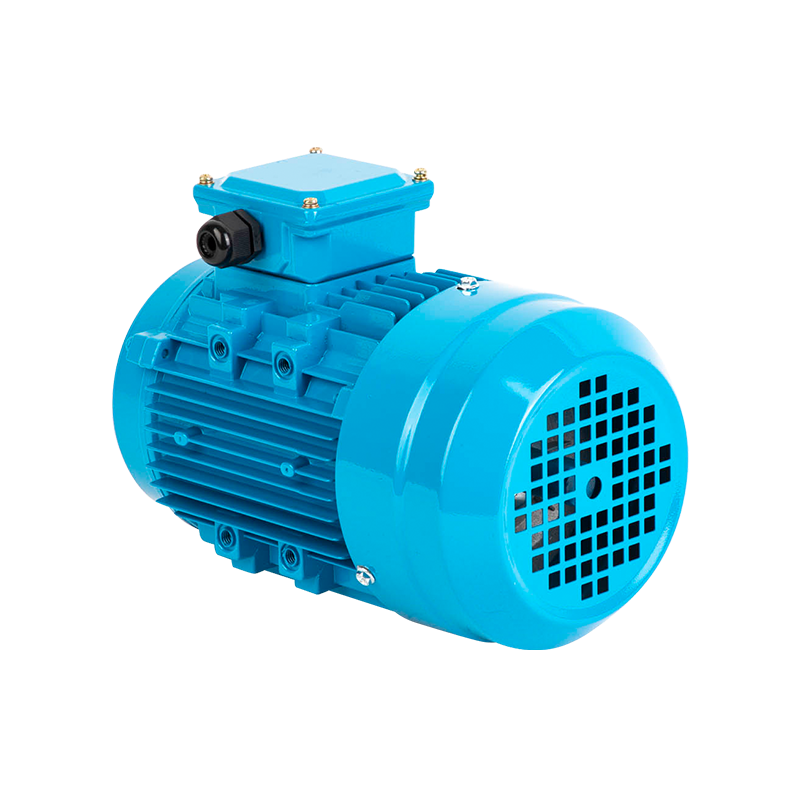

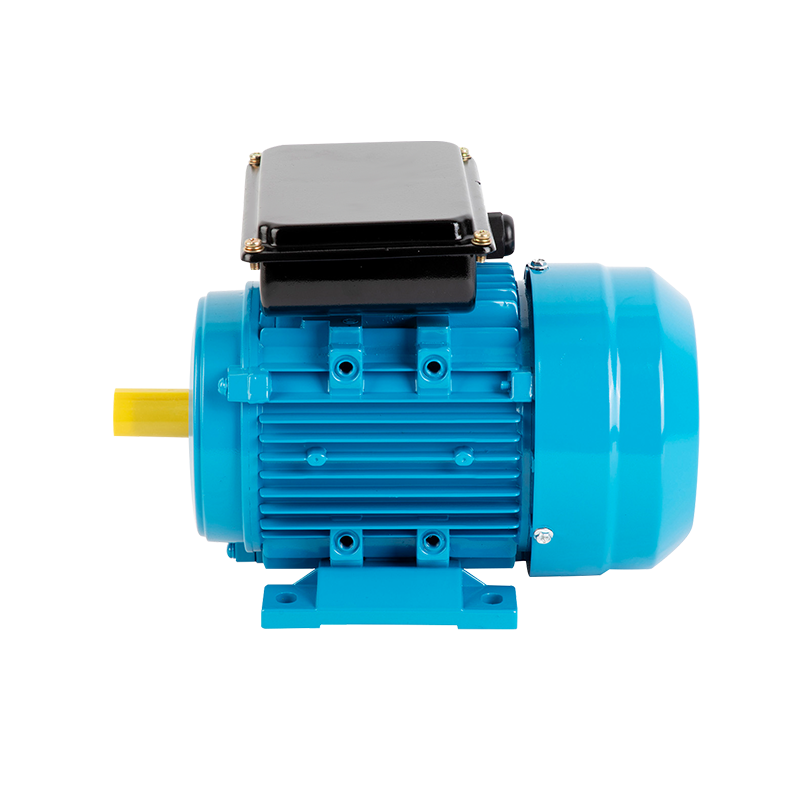

What Is a B3 Electric Motor?

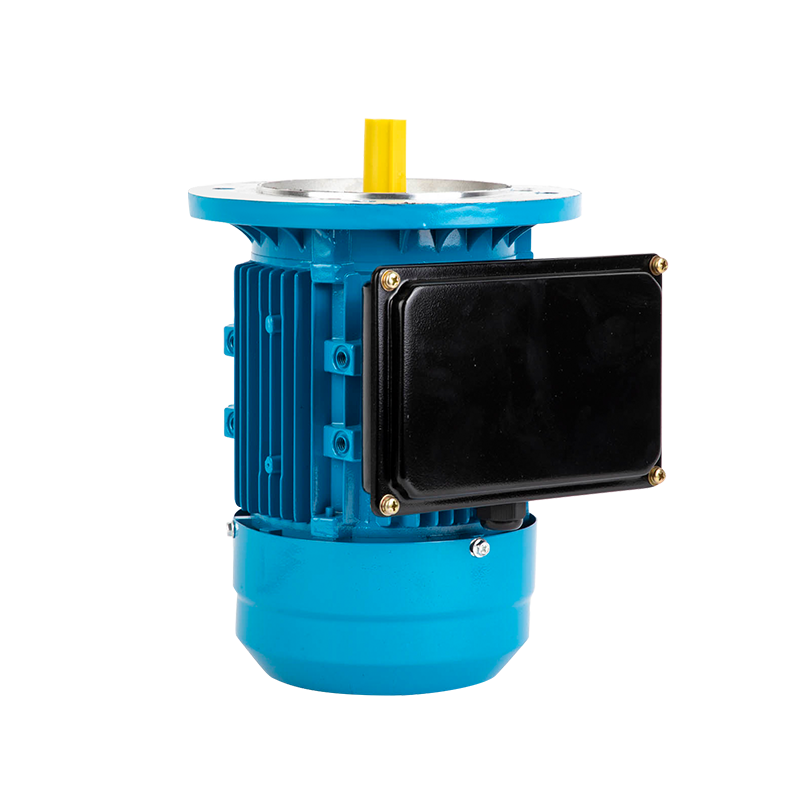

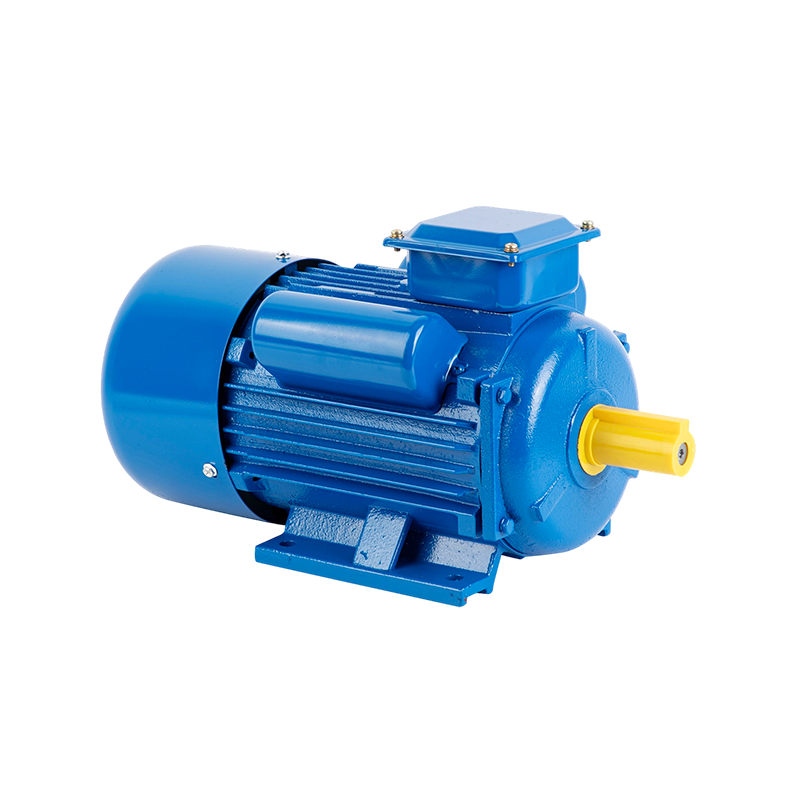

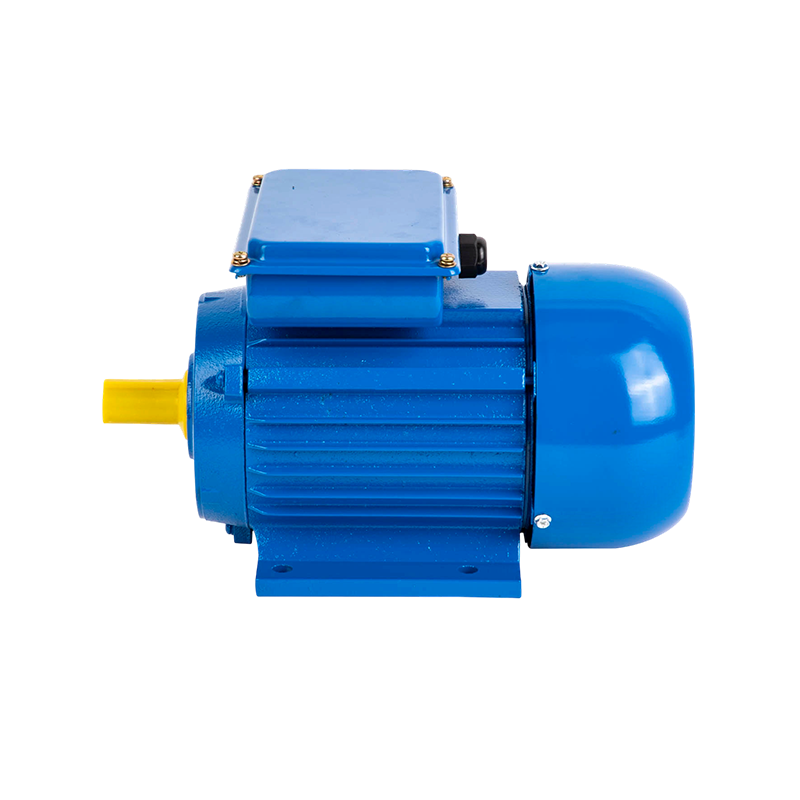

A B3 Electric Motor refers to an electric motor with a specific mounting configuration defined by the International Electrotechnical Commission (IEC). The B3 designation indicates a foot-mounted horizontal motor without a flange. This configuration is one of common and widely used in various industrial applications.

Understanding the Three-Phase B3 Motor

The Three-Phase B3 Motor is an asynchronous (induction) motor powered by a three-phase alternating current (AC). These motors are known for their simplicity, durability, and efficiency, making them suitable for a wide range of applications.

Key Features:

- Power Range: Typically from 0.75 kW to over 315 kW, accommodating various industrial needs.

- Efficiency Classes: Available in IE1, IE2, IE3, and IE4, aligning with international energy efficiency standards.

- Protection Classes: Commonly rated IP55, providing protection against dust and water ingress.

- Cooling Methods: Often utilize IC411 (totally enclosed fan-cooled) systems to maintain good operating temperatures.

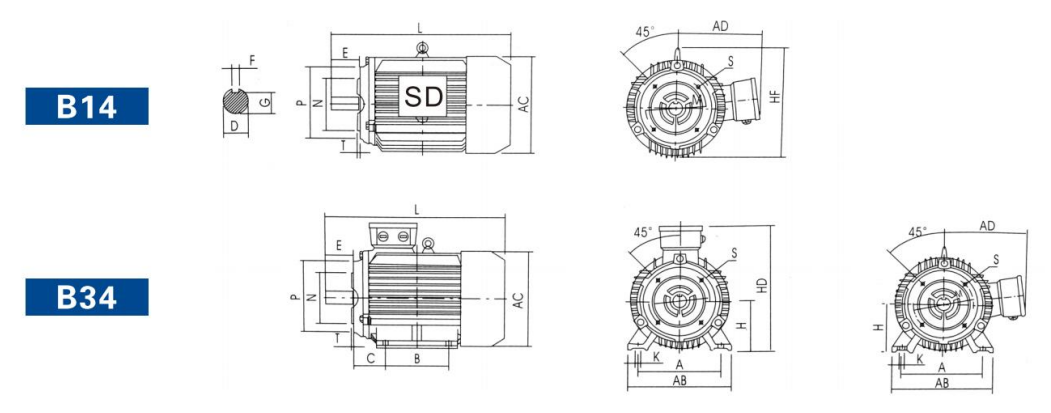

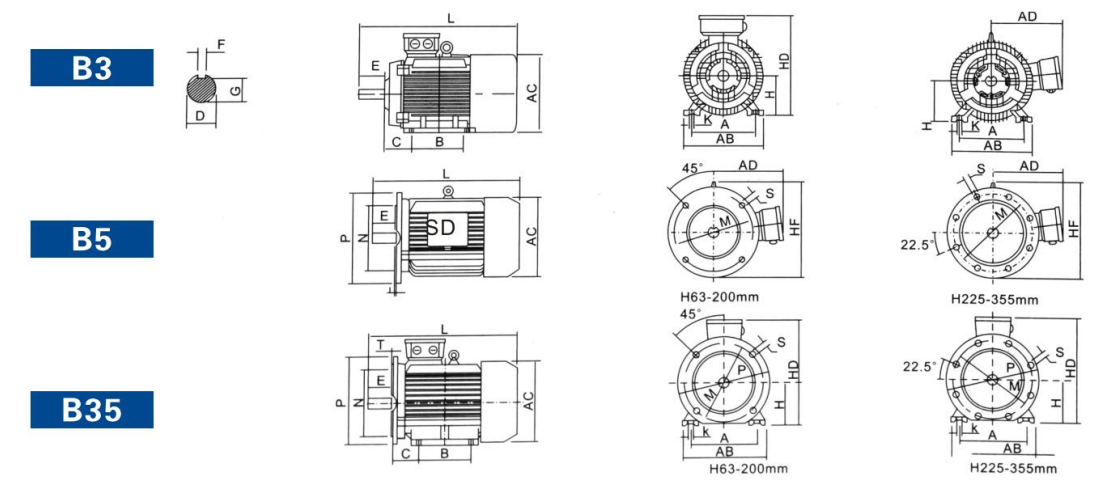

- Mounting Options: While B3 is standard, these motors can also be configured with B5 (flange) or B14 (face) mountings for specific applications.

These motors are versatile and can be used in various applications, including pumps, fans, conveyors, and compressors.

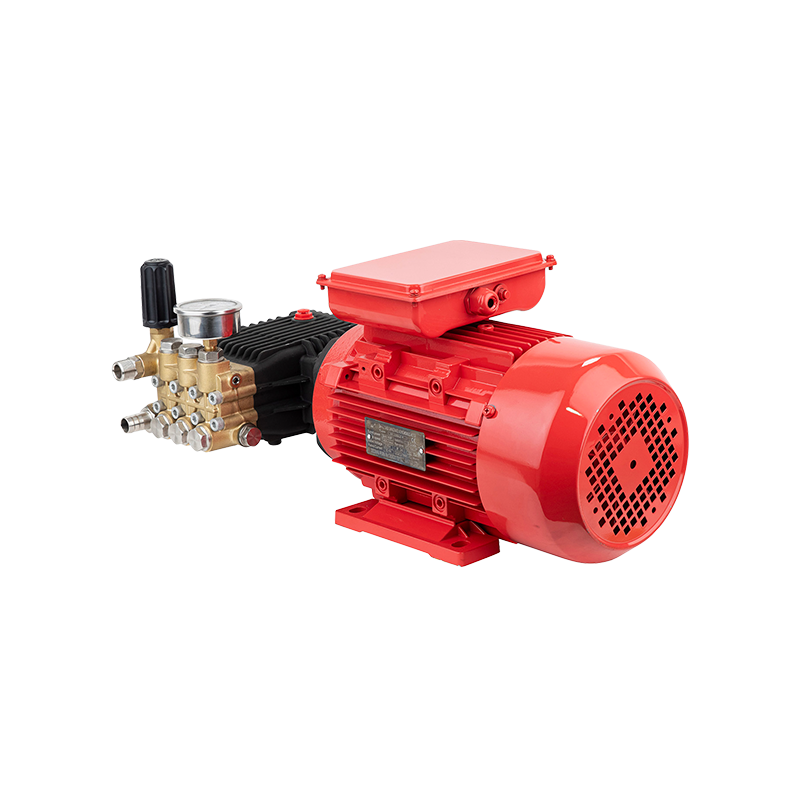

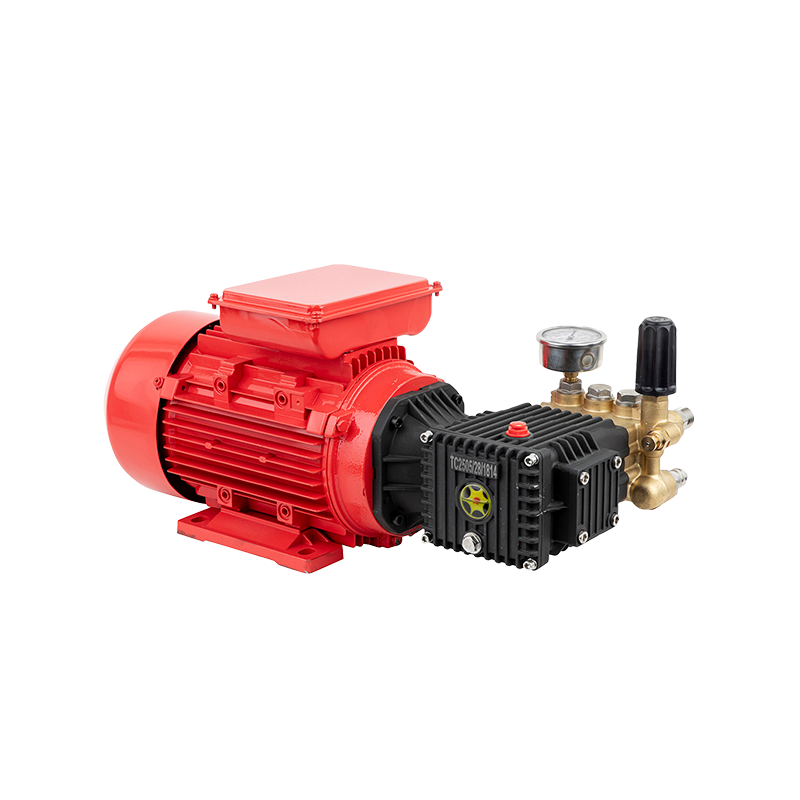

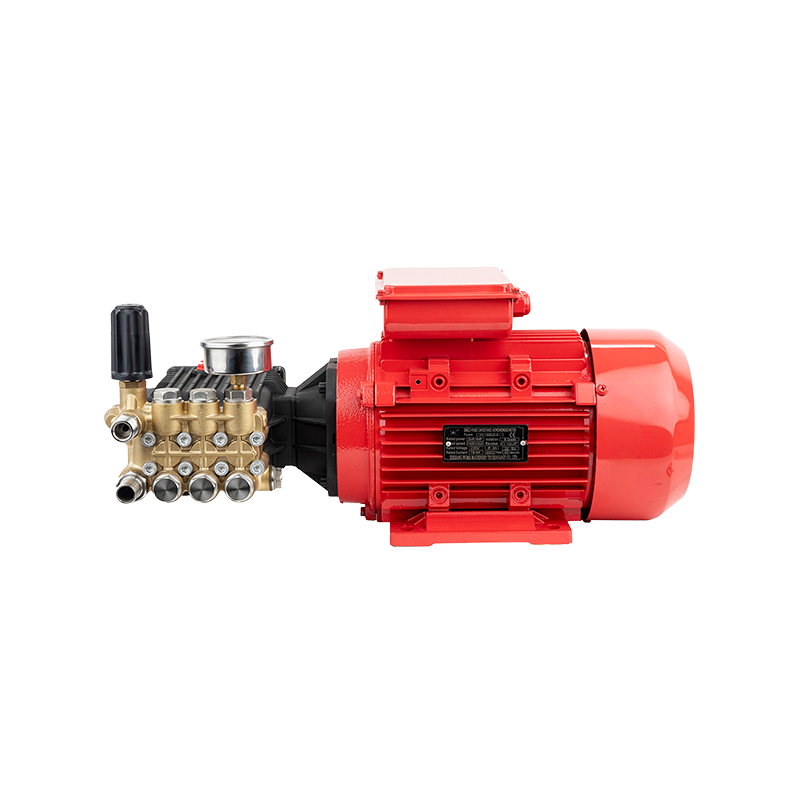

B3 Mounting Asynchronous Motor: Design and Applications

The B3 Mounting Asynchronous Motor is characterized by its foot-mounted design, which allows for horizontal installation. This mounting configuration is ideal for applications where the motor is bolted directly onto a base or frame, providing stability and support.

Design Considerations:

- Foot-Mounted Configuration: The motor features feet that allow it to be mounted horizontally on a base.

- Terminal Box Position: Typically positioned at the top (IM B3) for easy access and wiring.

- Cooling and Ventilation: Designed for good airflow to prevent overheating during continuous operation.

- Durability: Constructed with robust materials to withstand industrial environments and ensure long service life.

Applications:

B3 mounting asynchronous motors are widely used in various industries due to their reliability and versatility. Common applications include:

- Pumps: For water, oil, and chemical transfer.

- Fans and Blowers: In HVAC systems and industrial processes.

- Conveyors: For material handling in manufacturing and logistics.

- Compressors: In refrigeration and air conditioning systems.

Manufacturer's Production Advantages

Manufacturers specializing in B3 mounting asynchronous motors often highlight several key production advantages:

- Advanced Manufacturing Techniques: Utilization of CNC machining and automated assembly lines ensures precision and consistency in motor production.

- Quality Materials: Use of high-grade materials such as copper windings and high-strength steel frames contributes to the durability and efficiency of the motors.

- Customization Capabilities: Ability to tailor motor specifications, including voltage ratings, shaft lengths, and mounting configurations, to meet specific application requirements.

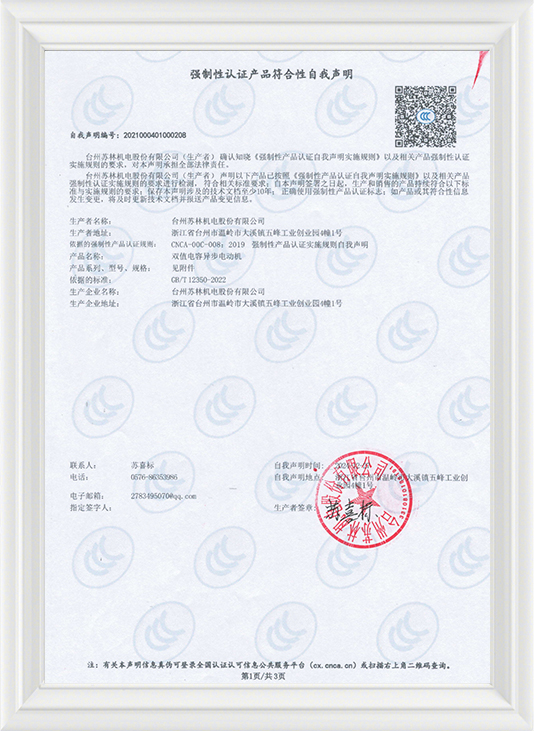

- Global Certifications: Compliance with international standards such as ISO9001, CE, and UL certifications assures customers of the motor's quality and safety.

Applications Across Industries

B3 mounting asynchronous motors are integral to various sectors:

- Manufacturing Automation: Robotic arms, CNC machines, and packaging systems.

- Textiles and Printing: Precise speed and torque control for fabric processing and printing quality.

- HVAC and Pumps: Asynchronous motor drives powering compressors, fans, and circulation systems.

- Logistics: Conveyor and sorting systems for warehouses and e-commerce facilities.

By integrating B3 mounting asynchronous motors with automation systems, manufacturers help industries achieve higher productivity, reduced waste, and smarter energy usage.

The combination of B3 mounting asynchronous motors reflects the growing demand for efficiency, precision, and adaptability in modern industries. From water pumps and conveyors to robotics and smart factories, these motors serve as the backbone of automation. For buyers, sourcing directly from manufacturers ensures access to customized, high-efficiency, and internationally certified solutions that improve long-term value.

If you require further information on selecting the appropriate motor for your specific application or need assistance with customization options, feel free to ask!