Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

In modern industries, efficiency is one of the main goals driving equipment selection and system design. From manufacturing to water treatment and chemical processing, pump motors play a crucial role in maintaining smooth and consistent operations. Choosing the right pump motor and working with a reliable Industrial Pump Motor Supplier can directly affect how efficiently a facility runs. But how exactly do pump motors influence industrial process efficiency?

The Role of Pump Motors in Industrial Operations

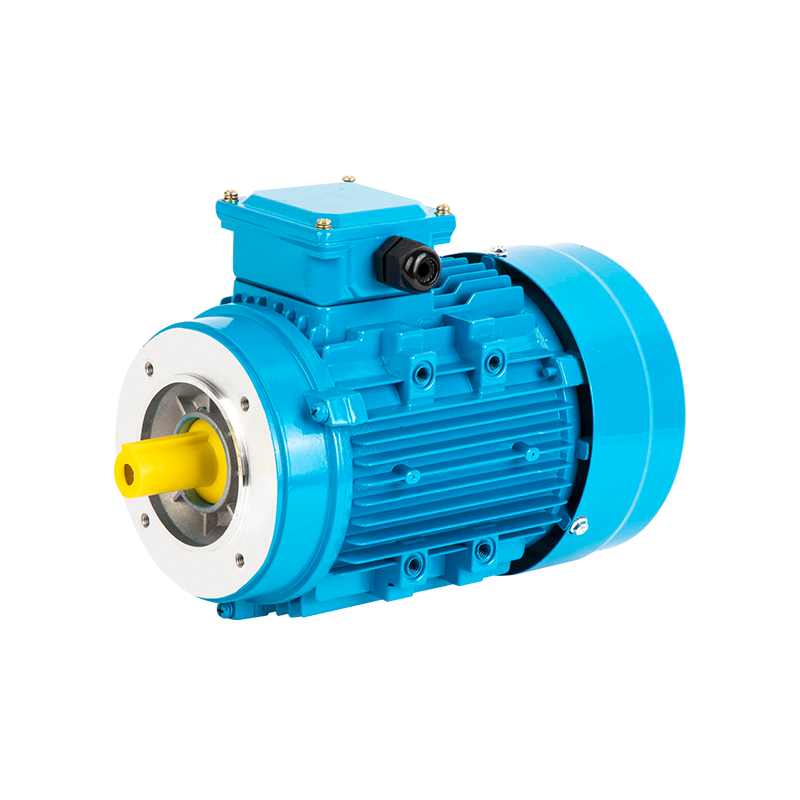

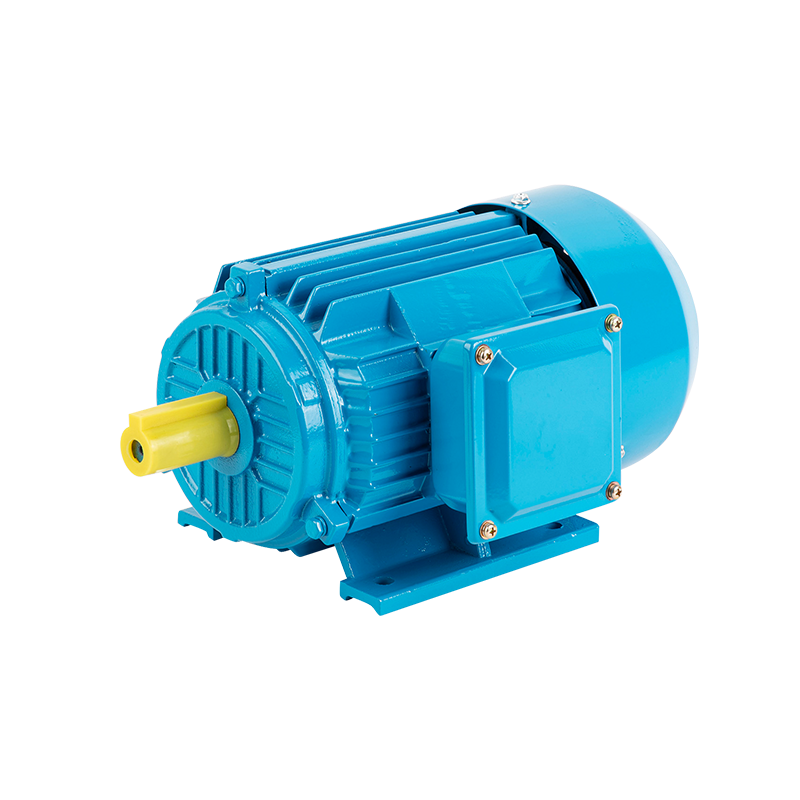

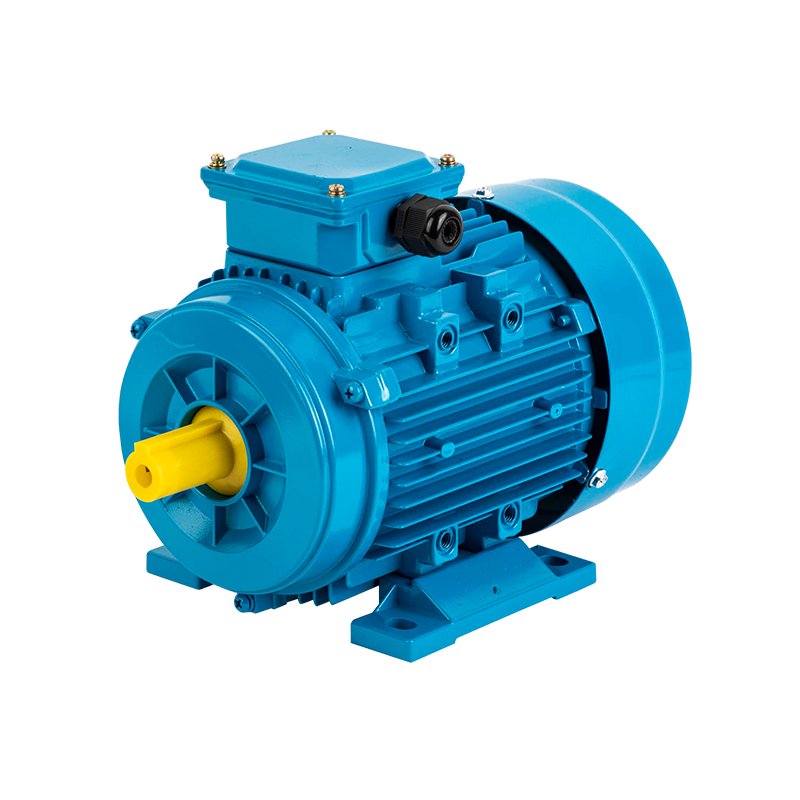

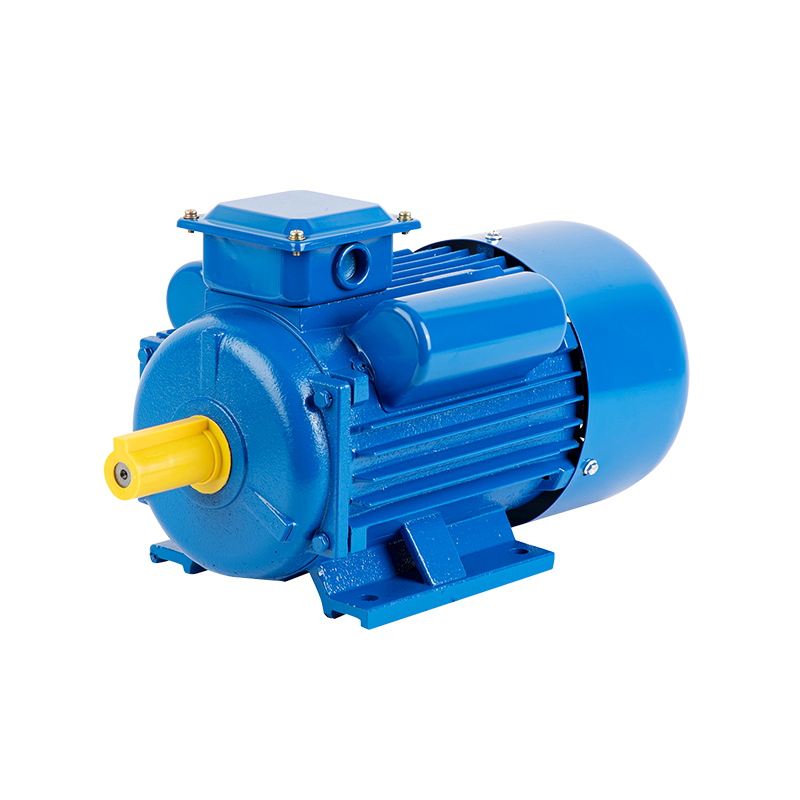

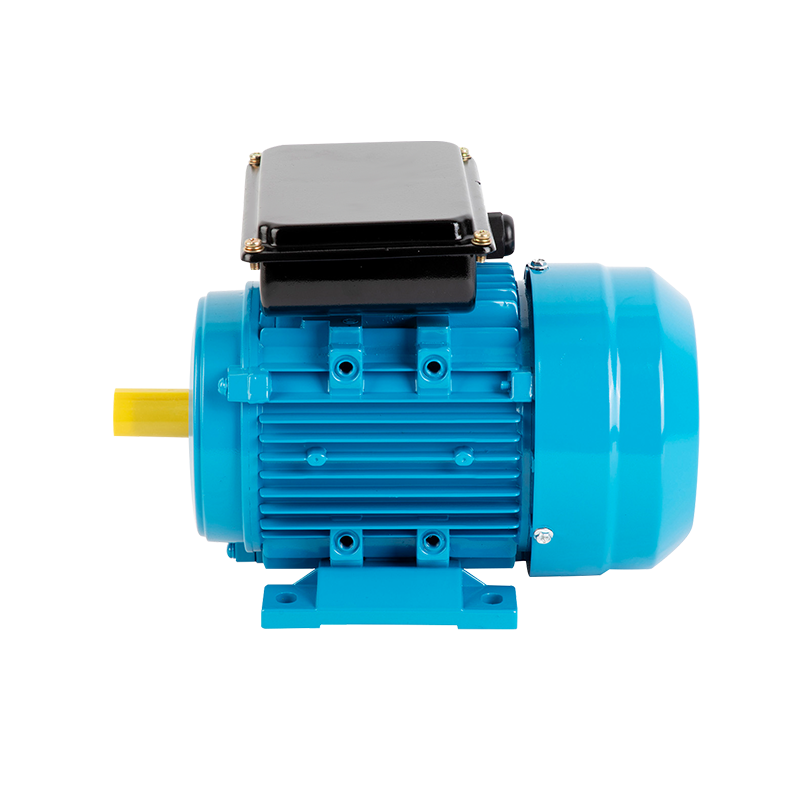

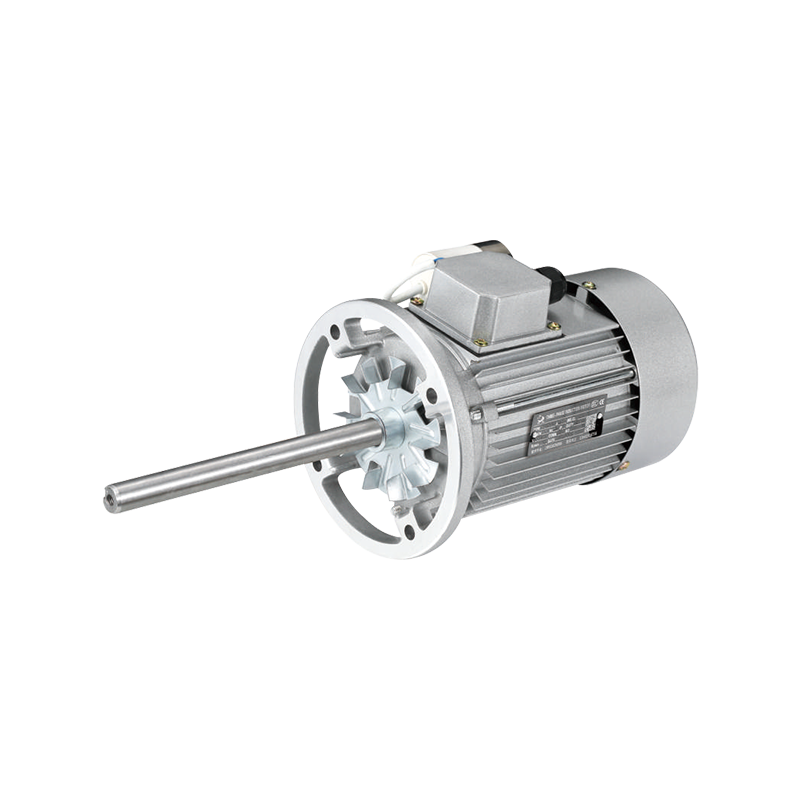

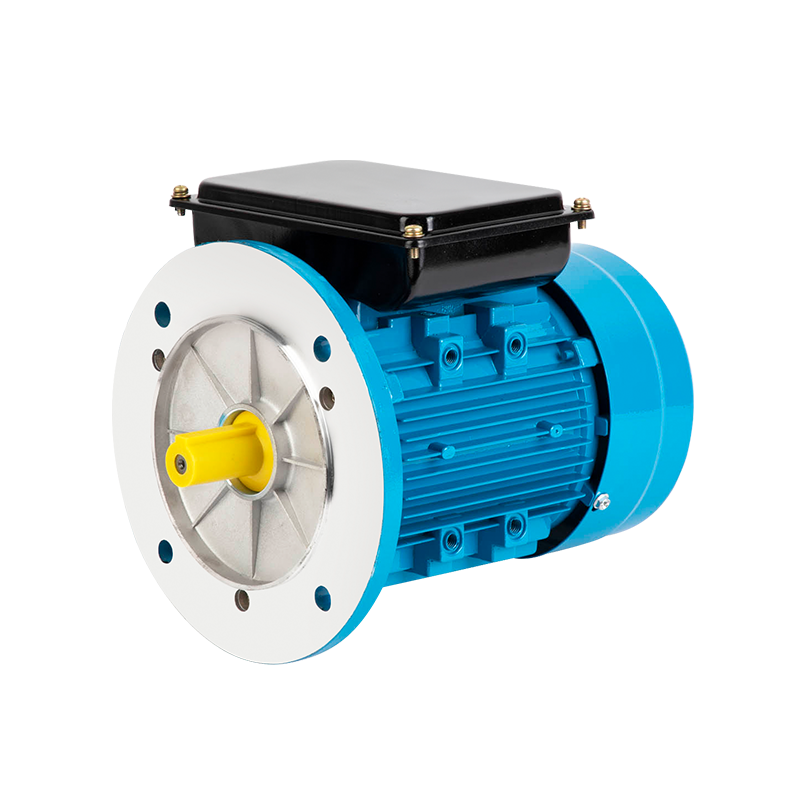

Pump motors are the driving force behind countless systems that move liquids, gases, or slurries through pipelines and machinery. Whether used in cooling systems, oil circulation, or wastewater treatment, these motors ensure stable pressure and consistent flow. When designed and maintained properly, they not only support continuous operation but also help reduce downtime and energy waste.

Industrial processes depend heavily on reliability and steady output. If a pump motor fails, the entire production line might come to a halt. That's why selecting a suitable unit from an experienced Industrial Pump Motor Supplier is essential. Such suppliers provide motors that meet different performance standards and fit specific environmental or operational conditions.

How Pump Motors Affect Energy Efficiency

Energy consumption remains a major concern in many factories and plants. Inefficient motors can waste significant amounts of electricity, directly increasing operational costs. By contrast, well-designed pump motors offer improved torque and better load control, allowing them to operate with less power while maintaining the same output.

Modern pump motors are often equipped with variable frequency drives (VFDs), which allow speed adjustment according to demand. Instead of running at a fixed speed all the time, these systems adapt to flow requirements, saving energy during periods of lower usage. Working with an Industrial Pump Motor Supplier that provides energy-efficient solutions can therefore make a noticeable difference in long-term energy savings.

Maintenance and Lifespan Considerations

Efficiency doesn't only come from performance—it also depends on maintenance and durability. A motor that requires frequent repairs or replacement parts can reduce the overall efficiency of industrial operations. Regular inspections, lubrication, and temperature control help extend the lifespan of pump motors.

Many Industrial Pump Motor Suppliers now offer motors built with corrosion-resistant materials, improved bearings, and advanced cooling systems. These features reduce wear and tear, ensuring stable operation even under demanding conditions. Investing in durable motors may require a higher upfront cost, but it usually results in lower maintenance expenses over time.

Automation and Smart Monitoring

The integration of smart monitoring systems has further enhanced the efficiency of industrial processes. Sensors can now track vibration, temperature, and energy use in real-time, allowing early detection of potential issues. This predictive approach reduces unexpected breakdowns and minimizes production interruptions.

An Industrial Pump Motor Supplier that supports automation-ready equipment can help businesses transition toward smarter systems. By combining digital monitoring with energy-efficient designs, manufacturers can achieve better control over their production environments while reducing waste and downtime.

Selecting the Right Partner

Not all pump motors are created equal, and neither are the companies that supply them. When choosing an Industrial Pump Motor Supplier, factors such as technical support, customization options, and after-sales service should be carefully evaluated. A dependable supplier can provide not only quality motors but also valuable guidance in selecting the great configuration for a specific process.

Working closely with such a partner allows industries to implement tailored solutions that meet both operational and sustainability goals. Over time, this collaboration can significantly improve efficiency and productivity across multiple departments.

Pump motors are far more than simple mechanical components—they are integral to achieving efficient, stable, and cost-effective industrial processes. Through careful selection, proper maintenance, and the support of a trusted Industrial Pump Motor Supplier, companies can improve their overall performance while reducing energy consumption and operational downtime. In a world where efficiency and sustainability matter more than ever, the right pump motor can make a meaningful difference in how industries operate.