Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

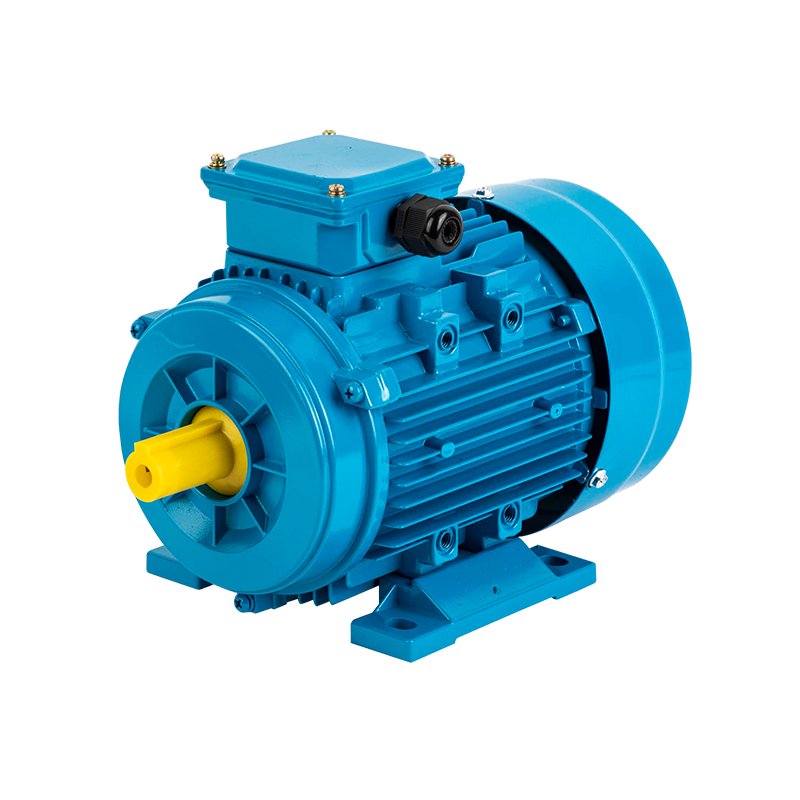

In the evolving landscape of industrial machinery and automation, energy efficiency and cost optimization have become essential considerations. Among the components contributing to this progress is the Vacuum Pump Motor, an integral part of systems where air removal, suction, or pressure regulation is required. Designed to support high performance with minimal energy consumption, the Vacuum Pump Motor offers a compelling solution for businesses aiming to improve operational efficiency without increasing power demands.

Understanding the Role of the Vacuum Pump Motor

The Vacuum Pump Motor is the driving force behind various vacuum systems, responsible for powering pumps that evacuate air or gases from enclosed spaces. These motors are commonly used in applications such as packaging, electronics manufacturing, medical devices, laboratory systems, and HVAC installations. The efficiency and reliability of a vacuum system often depend heavily on the performance characteristics of the Vacuum Pump Motor.

In environments where continuous operation is required, the energy demand of each motor adds up significantly. As a result, selecting a Vacuum Pump Motor that delivers high output with lower electricity consumption can have a measurable impact on long-term operating costs.

High Efficiency Through Advanced Design

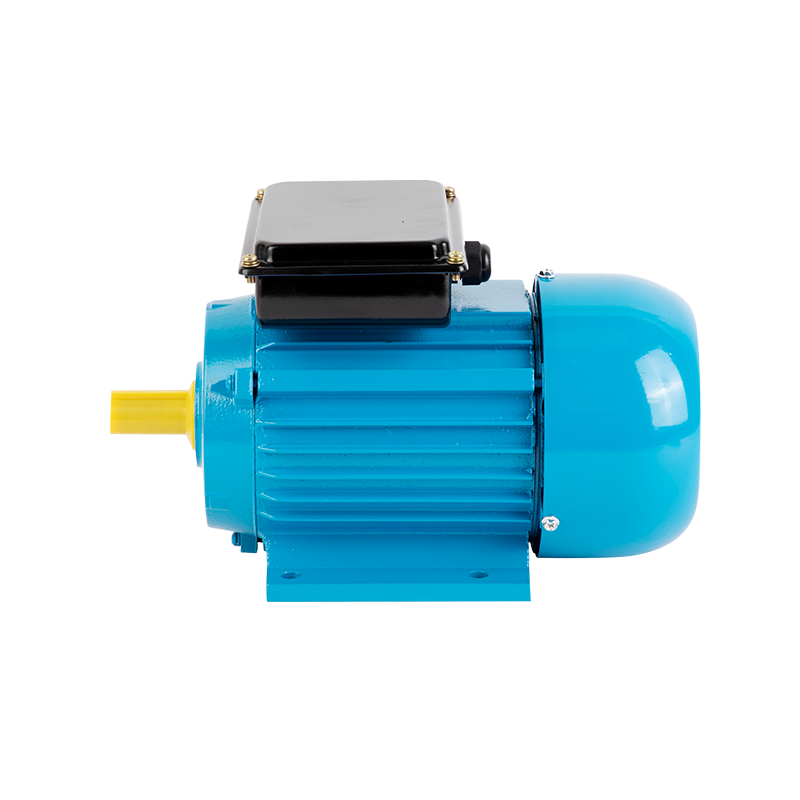

One of the standout advantages of a high-performance Vacuum Pump Motor is its electromagnetic efficiency. The internal structure of the motor—especially the design of the stator and rotor—is optimized to maximize energy transfer and minimize electrical losses. This efficient conversion of electrical power into mechanical motion ensures that more of the input energy contributes directly to productive work, reducing waste and improving overall system performance.

By incorporating precision-engineered winding patterns, high-grade magnetic materials, and optimized cooling systems, the Vacuum Pump Motor minimizes resistance and heat buildup. These improvements contribute to higher power factors and more stable motor function, even under demanding workloads.

Lower Power Consumption in Continuous Use

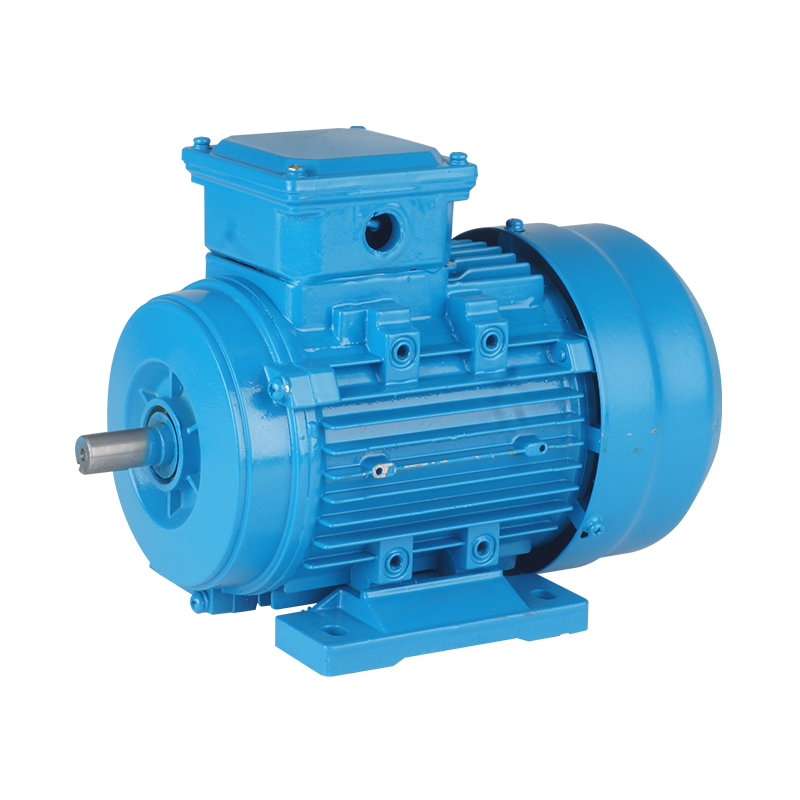

In many industrial settings, vacuum systems run for extended periods. The Vacuum Pump Motor, when designed for energy-saving operation, can significantly lower cumulative energy consumption across daily shifts and months of use. Reduced electricity usage directly translates to lower utility bills and helps companies meet their sustainability goals.

Unlike conventional motors that may require oversizing to maintain pressure stability, an energy-efficient Vacuum Pump Motor delivers consistent output without excess capacity. This precise matching of motor performance to system requirements avoids unnecessary energy drain and enhances process control.

Economic Benefits of Energy-Efficient Operation

The financial advantage of using a low-consumption Vacuum Pump Motor becomes apparent in both immediate and long-term calculations. For companies operating several vacuum systems across production lines, even marginal reductions in power usage can result in substantial savings over time.

Additionally, modern Vacuum Pump Motor models are often eligible for energy-efficiency certifications or subsidies offered in some regions. These benefits further incentivize the adoption of motors that are designed to deliver strong output with less power input.

Heat Management and Component Longevity

A key aspect of an efficient Vacuum Pump Motor is its ability to manage internal temperatures effectively. By reducing energy loss in the form of heat, these motors operate at lower surface temperatures, which helps extend the life of key components such as windings, insulation, and bearings.

Longer motor life means reduced downtime and maintenance costs—two critical factors in any industrial operation. The Vacuum Pump Motor, thanks to its energy-optimized structure, not only consumes less electricity but also contributes to the overall durability and reliability of the system.

Supporting Automation and Smart Systems

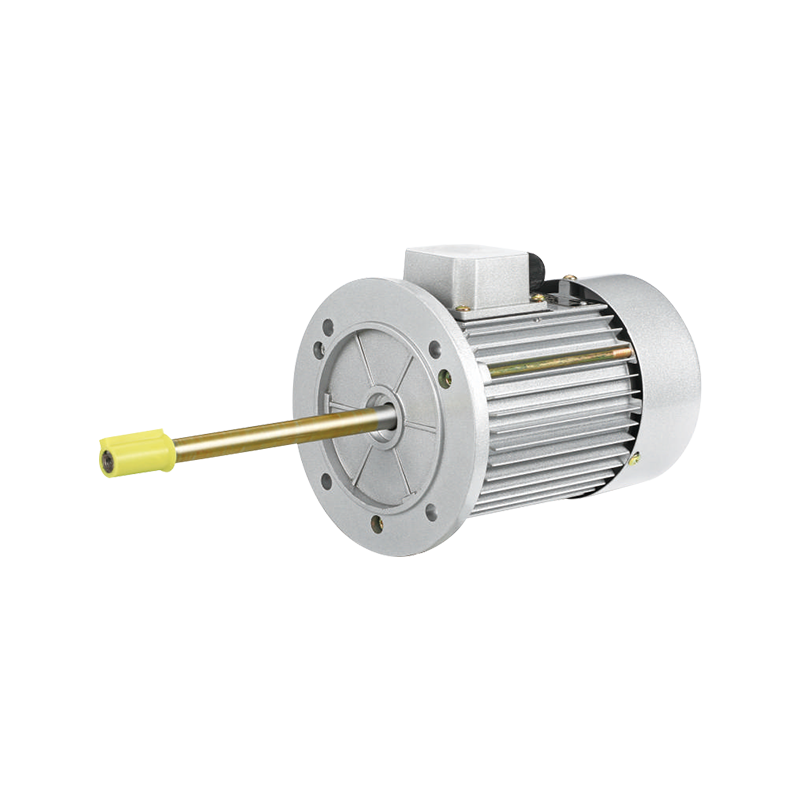

The growing integration of automated and smart control systems in industrial operations has increased the demand for energy-responsive components. The Vacuum Pump Motor, with its efficient power use and stable performance, is highly compatible with variable frequency drives (VFDs) and intelligent control panels.

These integrations allow for precise speed regulation and load adjustment, further enhancing the efficiency of the Vacuum Pump Motor. The ability to modulate motor performance based on real-time system demand reduces idle energy use and helps optimize operations across diverse applications.

Wide Application with Efficient Results

From laboratories requiring quiet, low-power vacuum operation to manufacturing plants needing powerful, energy-conscious motors, the Vacuum Pump Motor is suitable for a broad spectrum of uses. It can be found in semiconductor production, pharmaceutical processing, pneumatic systems, and many other areas where vacuum regulation is essential.

In each of these fields, the Vacuum Pump Motor plays a crucial role in supporting efficient workflow while reducing the energy footprint. This makes it an increasingly popular choice for system designers and maintenance engineers looking to balance performance with operational economy.

Incorporating a high-efficiency Vacuum Pump Motor into industrial and commercial systems presents a practical approach to enhancing performance while reducing energy costs. With its ability to convert electricity into motion more effectively, reduce heat generation, and integrate smoothly with modern control systems, the Vacuum Pump Motor stands out as a reliable, cost-saving component in today’s efficiency-driven industries.

As businesses continue to focus on sustainable practices and operational optimization, the Vacuum Pump Motor remains a key element in achieving those goals. Its energy-efficient operation supports both performance and economy, making it a valuable investment for any vacuum-based application.