Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

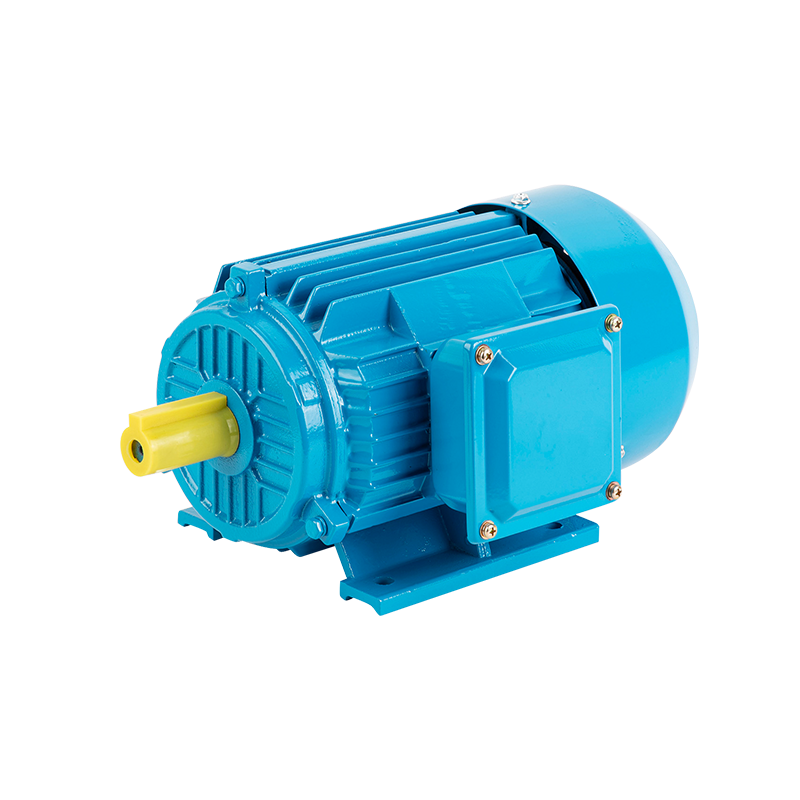

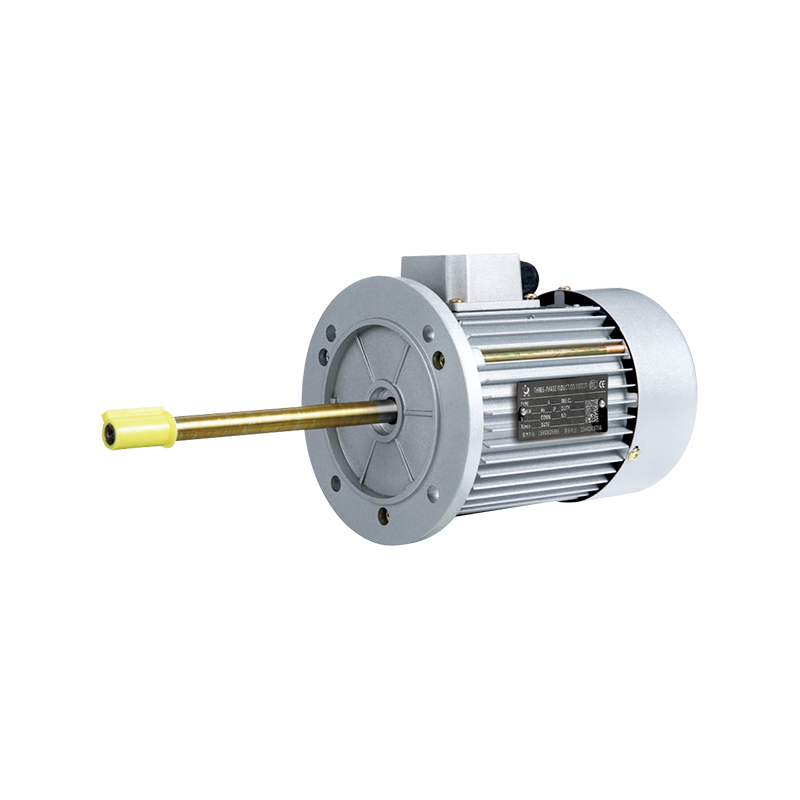

In the demanding climate and industrial landscape of the Middle East, equipment durability and consistent performance are paramount. Among the critical components driving a wide range of machinery, the 220V AC Motor has steadily gained recognition for its ability to meet the region’s unique operational challenges. From the scorching deserts to the humid coastal areas, the right motor can mean the difference between downtime and productivity.

Adapting to High Temperatures

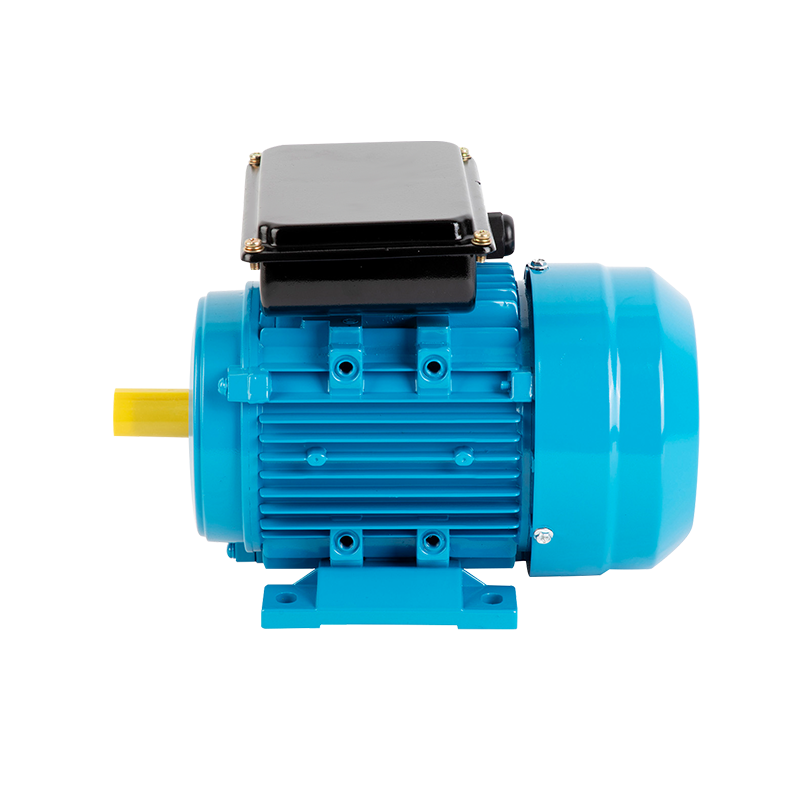

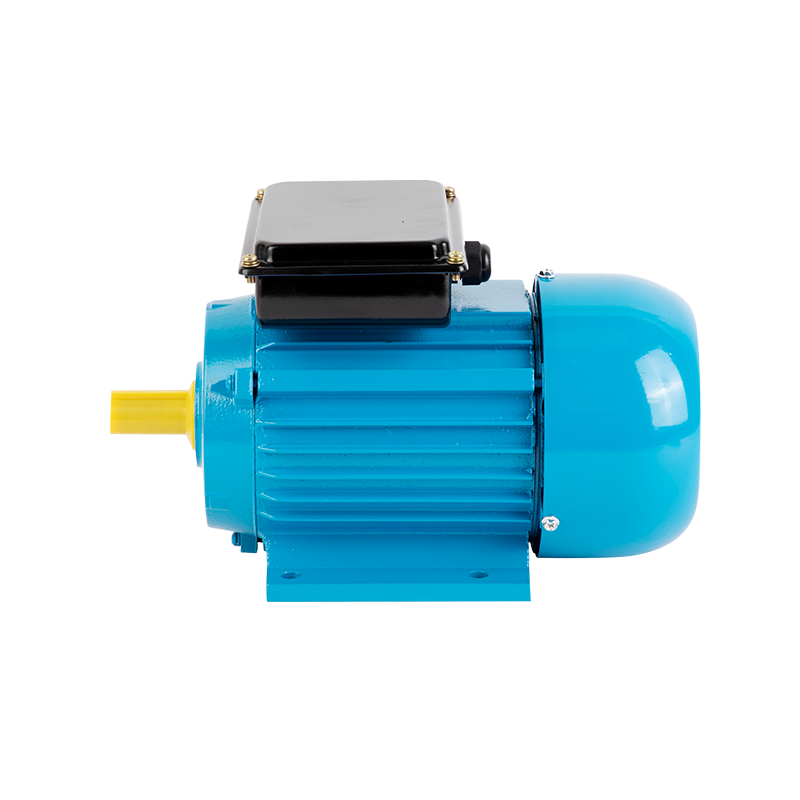

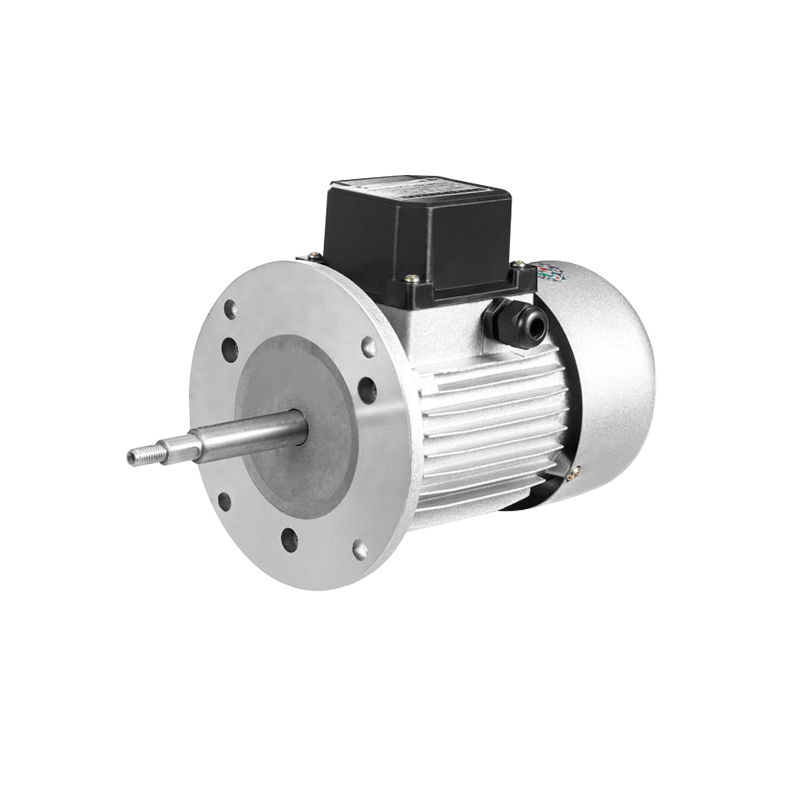

Middle Eastern summers are known for their relentless heat, often soaring well above 45°C. This presents a significant challenge for many electrical motors, where excessive heat can cause insulation breakdown, premature bearing wear, and unexpected shutdowns. The 220V AC Motor designed for this region typically incorporates high-grade insulation materials, such as F-class or even H-class insulation. These materials withstand elevated temperatures better than standard options, ensuring the motor continues to operate safely without deterioration.

Moreover, efficient cooling mechanisms are integral to these motors. Many models employ optimized airflow designs, including high-efficiency fans and heat-dissipating fins, which enhance heat dispersion. Combined with lubricants formulated specifically for high-temperature bearings, these features prevent overheating and maintain smooth operation throughout prolonged use. For industries ranging from water pumping in agricultural projects to conveyor systems in manufacturing plants, the stable performance of the 220V AC Motor in heat conditions is a vital asset.

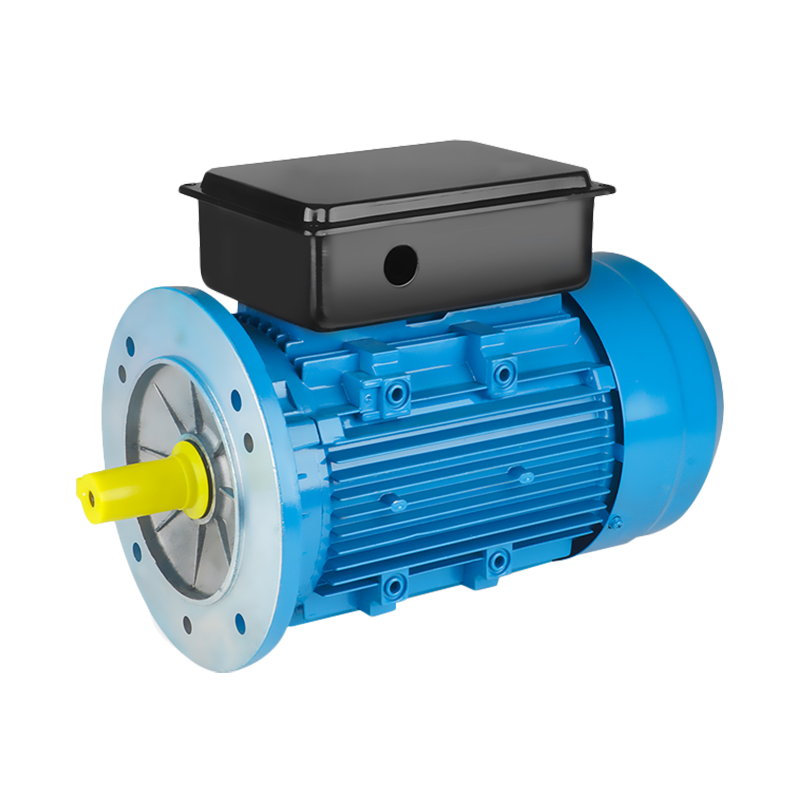

Protection Against Dust and Sand

The pervasive presence of dust and sand, particularly in desert areas of countries like Saudi Arabia and Oman, introduces another layer of complexity. Fine sand particles can infiltrate motor components, causing abrasion, clogging ventilation, and accelerating wear on bearings and winding insulation.

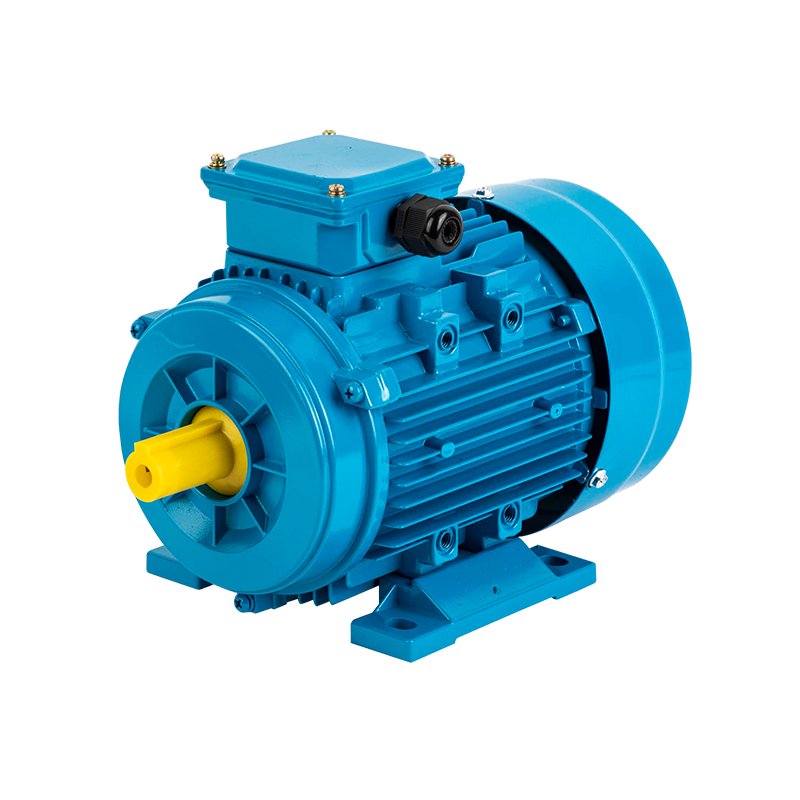

In response, 220V AC Motors suitable for the Middle East are engineered with robust ingress protection ratings such as IP55 or higher. This level of sealing effectively blocks dust and sand from entering the motor housing. Additionally, some specialized motors come with even more stringent protection to safeguard internal parts, reducing maintenance frequency and preventing costly repairs.

Industries like construction, mining, and oil & gas heavily benefit from such reliability, as their operations frequently take place in dusty outdoor environments. For instance, a case study involving a water treatment facility in Abu Dhabi highlighted the advantages of using these motors: despite continuous exposure to desert dust, the 220V AC Motor maintained steady output and required minimal servicing over multiple years.

Corrosion Resistance for Coastal Applications

The coastal regions of the Middle East, including areas in the UAE, Bahrain, and Qatar, face distinct challenges posed by high salt content in the air. Salt spray can rapidly corrode unprotected metals, to structural damage and electrical failures.

To counteract this, 220V AC Motors used in coastal and offshore industries incorporate corrosion-resistant features. Protective coatings, such as epoxy paints or powder coatings, shield the motor housing from salt-induced corrosion. Stainless steel fasteners and corrosion-resistant alloys are often used for external components to further enhance durability.

This is particularly important for sectors like desalination plants, marine applications, and offshore oil rigs, where equipment longevity is critical under harsh saline conditions. The ability of the 220V AC Motor to withstand such environments extends service life and reduces unexpected downtime, ultimately benefiting operational efficiency.

Industry Implications and Final Thoughts

The deployment of 220V AC Motors in the Middle East’s varied industrial sectors is a practical choice driven by proven resilience. Their design considerations—high-temperature insulation, dust ingress protection, and corrosion resistance—address key environmental challenges head-on. Manufacturers and end-users alike recognize that investing in motors tailored to these conditions yields long-term value through reduced maintenance costs and uninterrupted operations.

Whether powering irrigation pumps in vast desert farms, driving fans in coastal desalination plants, or moving materials in desert-based manufacturing facilities, the 220V AC Motor continues to demonstrate its relevance. As Middle Eastern industries expand and modernize, the demand for reliable motor technology adapted to local climates will only grow.

In conclusion, the 220V AC Motor stands out as a dependable solution capable of meeting the Middle East’s operational demands without compromise. Its robust engineering and thoughtful design make it an essential component for industries seeking steady performance in one of the world’s challenging environments.