Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

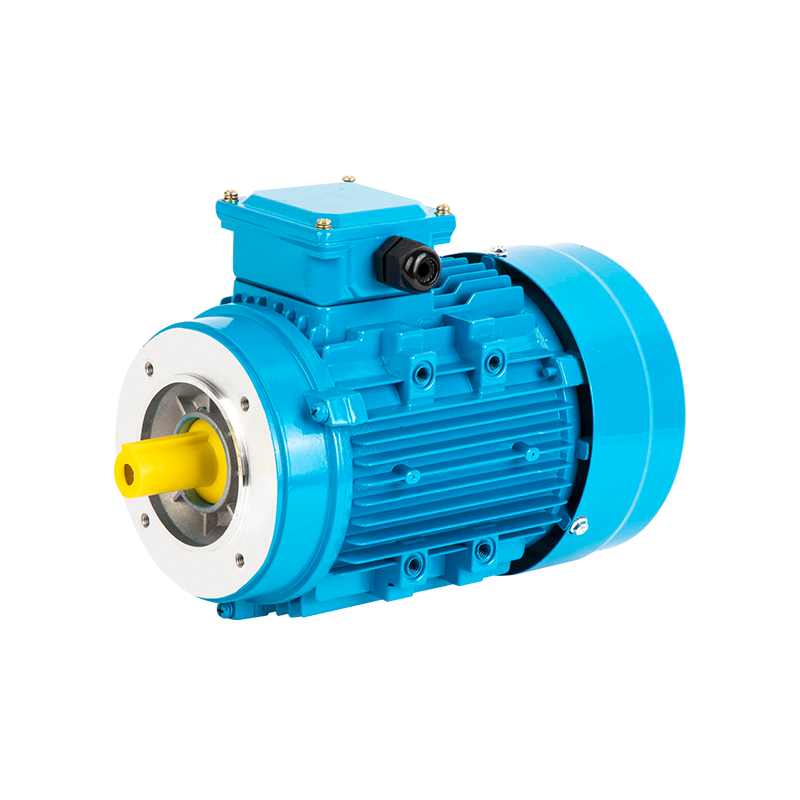

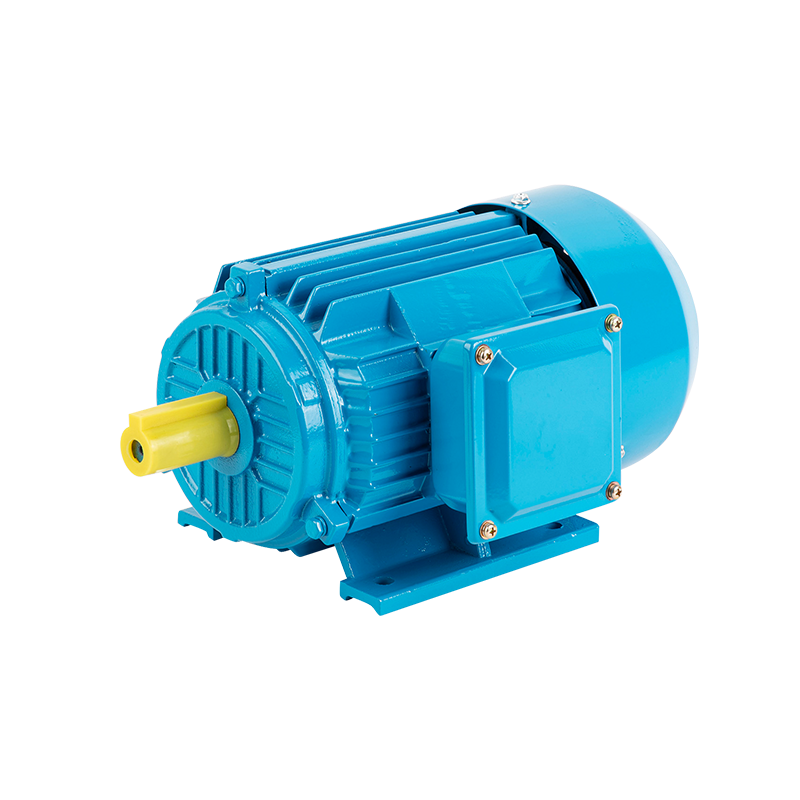

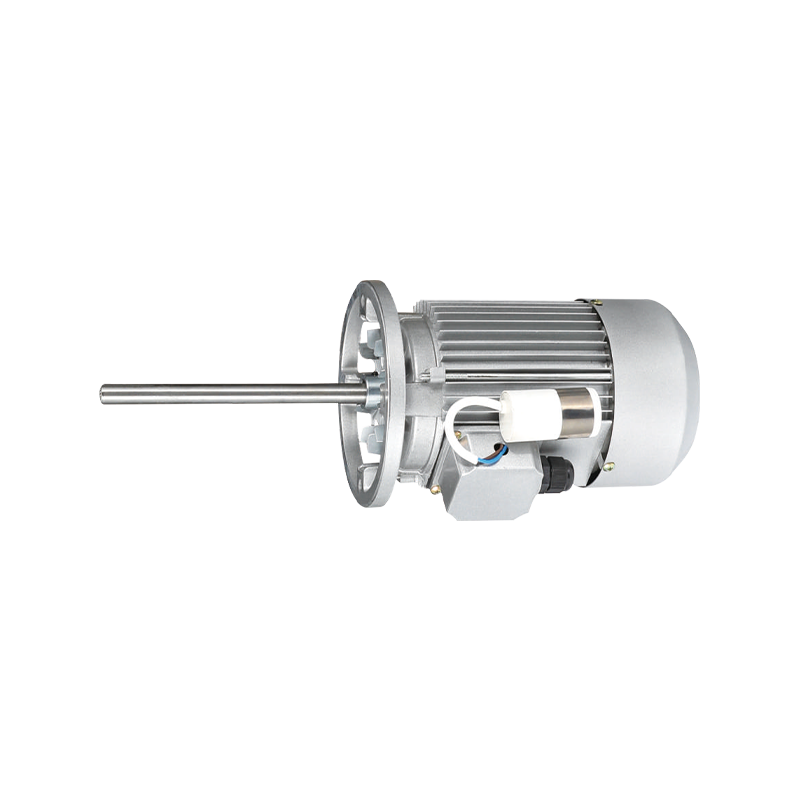

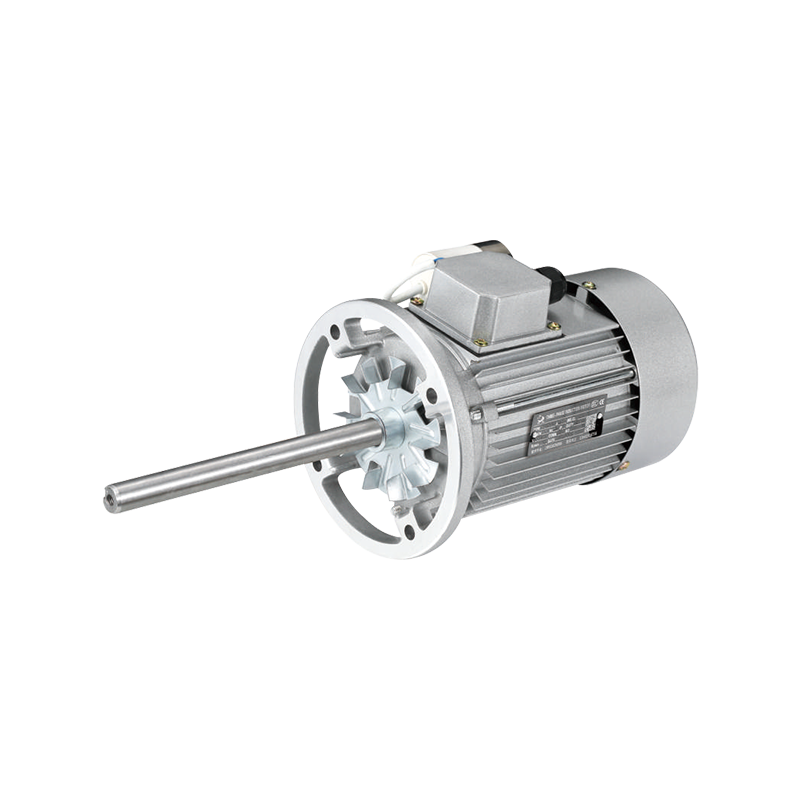

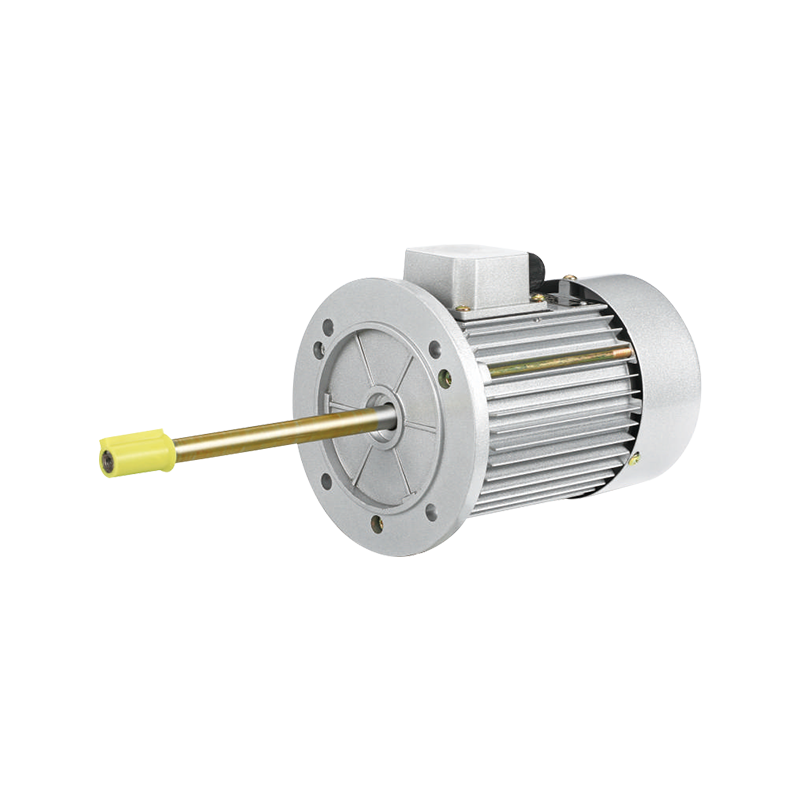

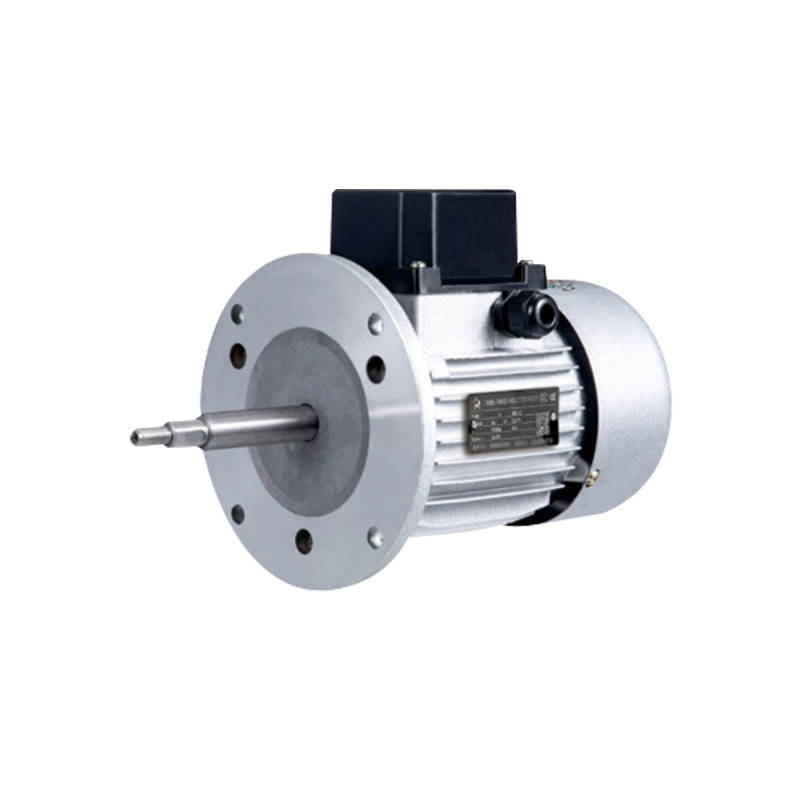

DC asynchronous electric induction motors, sometimes referred to as brushless DC motors with asynchronous operation characteristics, have become a key player in modern industrial applications. They combine the efficiency of DC control with the reliability and durability of asynchronous AC induction principles. These motors are widely used in manufacturing, automation, pumps, fans, and small machinery due to their robust performance and energy efficiency.

Key Advantages at a Glance:

| Benefit | Benefit |

| High Efficiency | Reduces energy consumption, lowering operational costs |

| Durability | Minimal maintenance due to brushless design |

| Compact Design | Easy integration into space-constrained machinery |

| Wide Application | Suitable for pumps, compressors, industrial fans, and conveyors |

1. Technological Innovations in DC Asynchronous Motors

The development of DC asynchronous electric induction motors has introduced several technological breakthroughs:

a. Enhanced Energy Efficiency

Modern designs utilize advanced rotor and stator configurations to reduce energy losses. By minimizing slip and improving magnetic flux, these motors provide outstanding efficiency compared to traditional induction motors.

b. Intelligent Control Systems

Integration with electronic speed controllers (ESCs) and variable frequency drives (VFDs) allows precise speed and torque control. This is particularly beneficial for applications like conveyor systems or automated machinery requiring consistent performance.

c. Reduced Maintenance

The elimination of brushes and commutators reduces mechanical wear, making these motors highly reliable in continuous operation environments, such as industrial pumps or HVAC systems.

2. Industrial Applications of DC Asynchronous Motors

These motors are highly versatile and widely used across multiple industries:

a. Pumping Systems

- Pressure Water Pumps: Smooth operation with consistent flow rate.

- Small Mechanical Pumps: Compact motors that fit tight spaces in machinery.

- Industrial Water Pumps: High-performance motors capable of handling large fluid volumes.

b. Fans and Ventilation

- Industrial Fans: High torque output ensures strong airflow even under heavy loads.

- HVAC Systems: Energy-efficient motors reduce power consumption in large-scale heating, ventilation, and air conditioning.

c. Small Machinery

- Mixers: Precise torque control allows smooth mixing operations in food and chemical processing.

- Grinders: Enhanced motor stability improves grinding consistency and safety.

Table of Example Applications:

| Application | Motor Advantage |

| Water Pumps | Energy-saving, reliable continuous operation |

| Industrial Fans | High torque, low vibration |

| Small Machinery | Compact size, precise speed control |

3. Customization Options for Industrial Needs

Manufacturers are increasingly offering tailored solutions to meet specific requirements:

- Voltage and Frequency Adaptation: Motors can be customized to match local power supply standards.

- Mounting Options: B3, B5, or flange mounting configurations depending on equipment design.

- Rotor and Stator Materials: Enhanced materials improve efficiency and thermal resistance.

- Integrated Control Systems: Custom ESCs or VFDs allow integration with factory automation.

4. Advantages Over Traditional Motors

Compared to traditional AC induction or brushed DC motors, DC asynchronous electric induction motors provide:

- Longer Lifespan: Brushless design reduces mechanical failures.

- Lower Operational Costs: Higher efficiency reduces electricity consumption.

- Noise Reduction: Smooth rotor operation lowers vibration and sound levels.

- Versatility: Adaptable for a variety of industrial processes from pumps to mixers.

5. Future Trends in Industrial Innovation

- IoT Integration: Smart sensors for predictive maintenance and real-time performance monitoring.

- Energy Optimization Algorithms: AI-driven control systems to minimize energy consumption.

- Sustainable Materials: Development of eco-friendly magnetic and copper materials.

- Compact High-Power Designs: Motors that deliver more power while taking up less space.

DC asynchronous electric induction motors represent a significant innovation in industrial motor technology. Combining the reliability of asynchronous motors with the precision and efficiency of DC systems, they address the growing demand for energy-efficient, low-maintenance, and versatile industrial machinery solutions. Their broad applicability—from water pumps to industrial fans and small machinery—demonstrates why they are becoming a standard choice for modern industrial applications.