Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

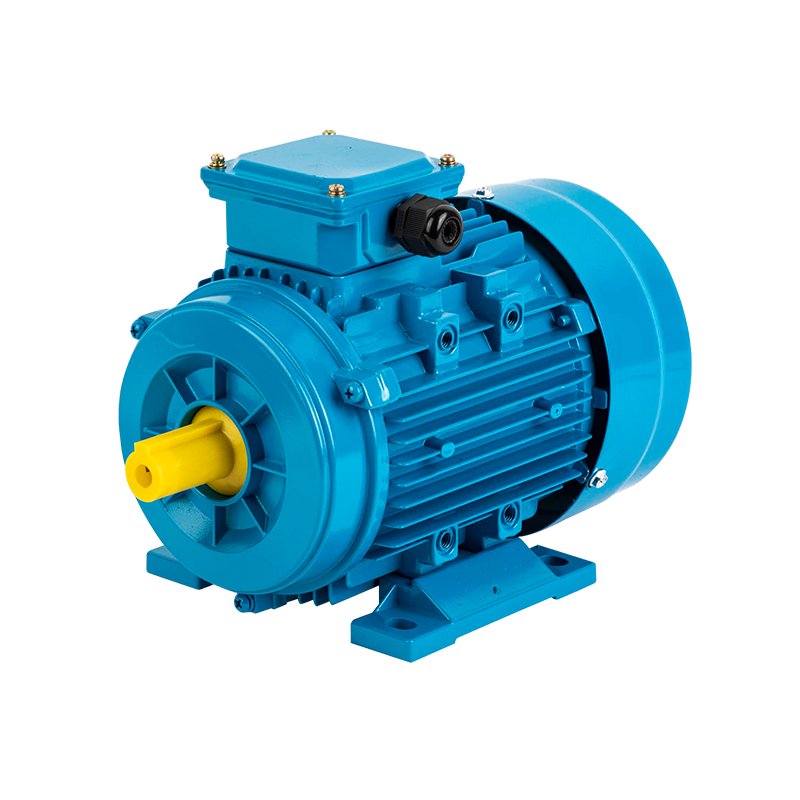

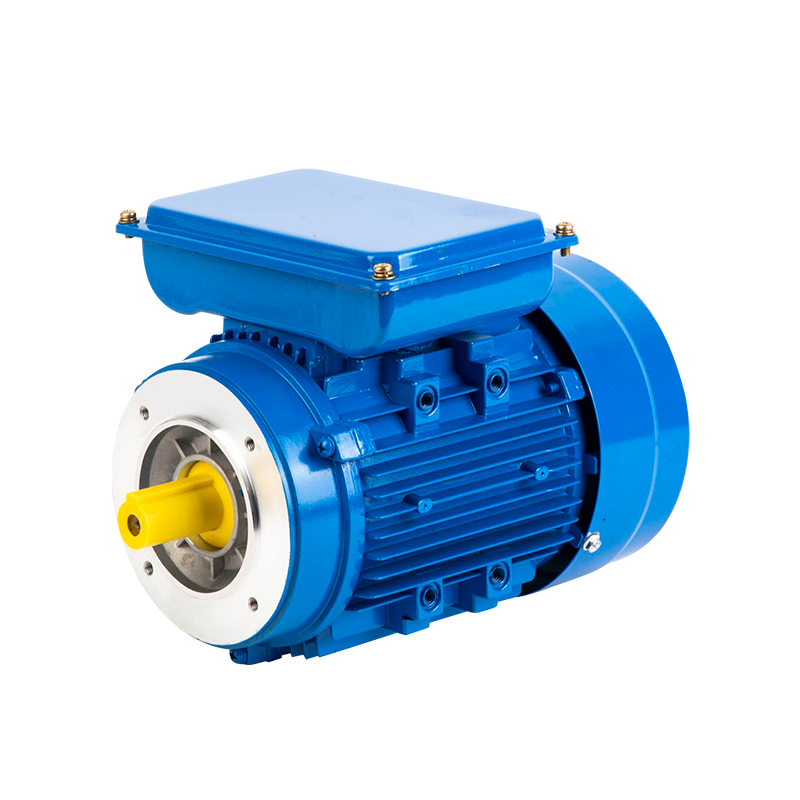

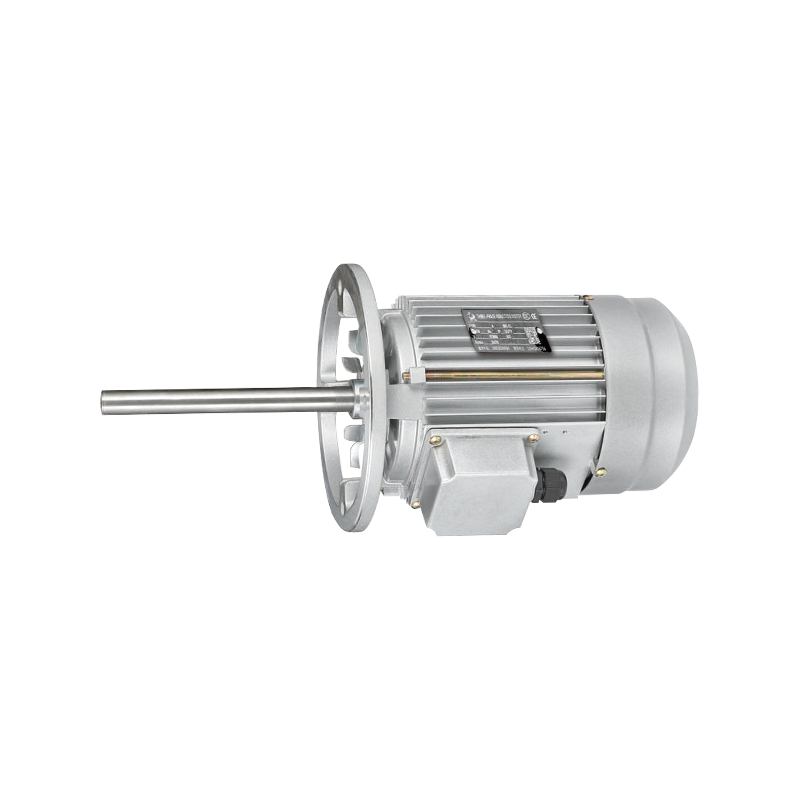

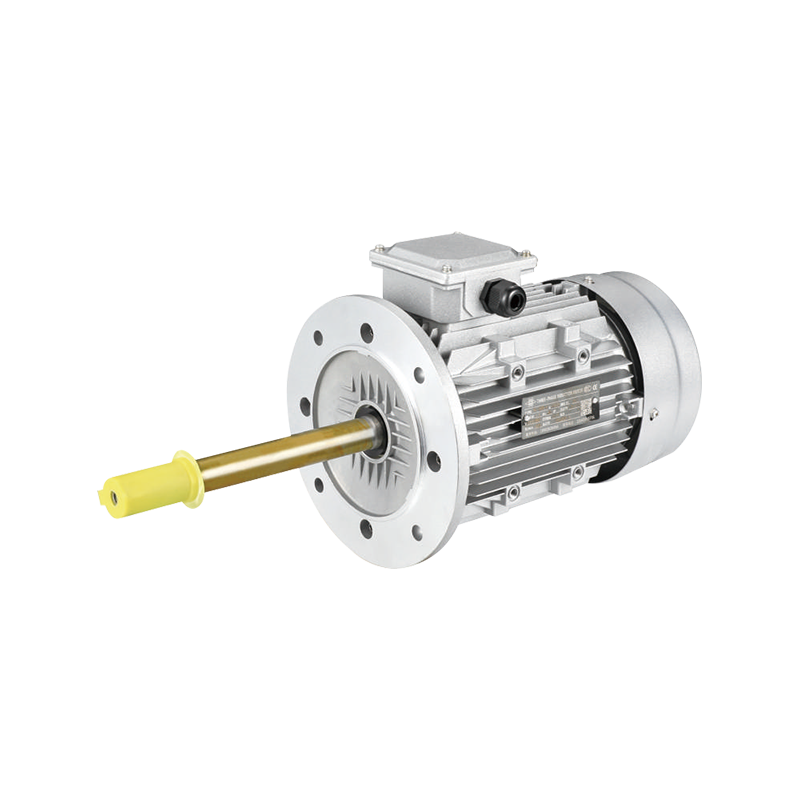

Fan motors are essential components in heating, ventilation, and cooling systems, as well as in industrial equipment and household appliances. As energy consumption becomes a growing concern, improving the efficiency of fan motors has become a priority for manufacturers. A Fan Motor Manufacturer focuses on design innovations, materials, and technology to reduce energy usage while maintaining performance.

Advanced Motor Designs

One of the primary ways fan motor manufacturers enhance efficiency is through improved motor design. Traditional motors can lose energy due to friction, heat, and resistance. By optimizing the winding configuration, rotor design, and bearing placement, a Fan Motor Manufacturer can reduce energy loss during operation. Brushless DC (BLDC) motors, for example, eliminate friction caused by brushes, causeing to smoother operation and reduced power consumption. Such designs allow motors to deliver the required airflow with less energy input.

High-Quality Materials

The materials used in fan motors significantly impact their energy efficiency. Manufacturers use high-grade copper for windings, which lowers electrical resistance and minimizes energy loss. Lightweight, durable materials for rotors and housings reduce the energy required to start and maintain rotation. A Fan Motor Manufacturer also considers magnetic materials for the core that can improve magnetic flux efficiency, further reducing energy waste. These material choices contribute to a more efficient and longer-lasting motor.

Precision Manufacturing and Tolerances

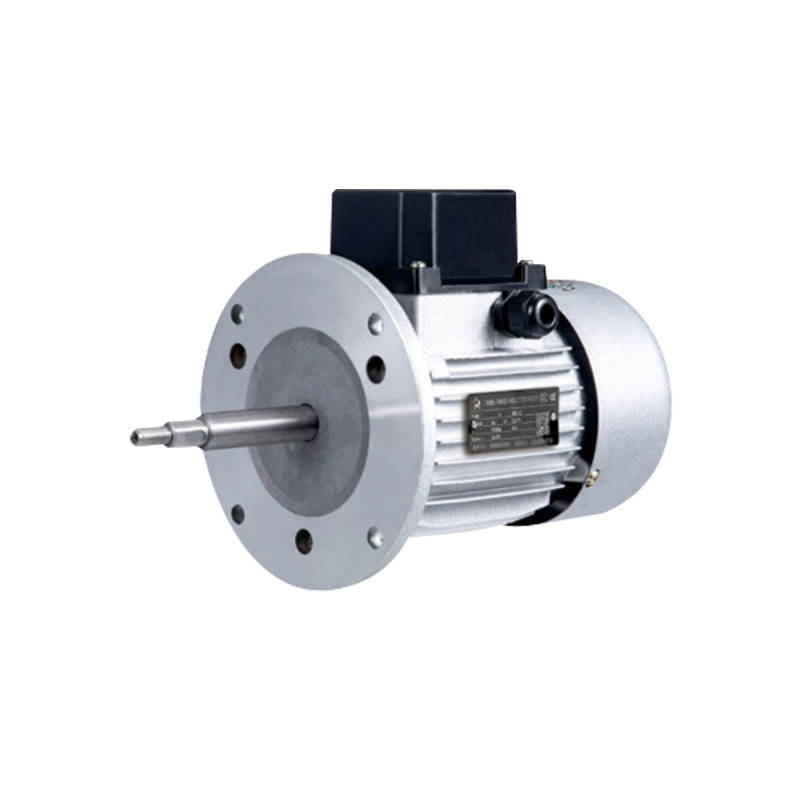

Precision engineering is another factor in energy-efficient fan motors. Tight manufacturing tolerances reduce vibration, friction, and mechanical losses, which can otherwise consume additional energy. A Fan Motor Manufacturer often employs advanced production techniques, such as CNC machining and computer-controlled assembly, to ensure components fit precisely and operate smoothly. This level of accuracy minimizes mechanical resistance, allowing the motor to function efficiently at various speeds and loads.

Smart Control Systems

Modern fan motors are often paired with electronic controllers that optimize energy usage. Variable speed drives (VSDs) and programmable logic controllers (PLCs) adjust motor speed according to demand, rather than running at full power constantly. A Fan Motor Manufacturer may integrate sensors and feedback systems that regulate airflow and energy consumption in real time. This approach reduces wasted energy, particularly in applications where airflow requirements fluctuate, such as HVAC systems or industrial ventilation.

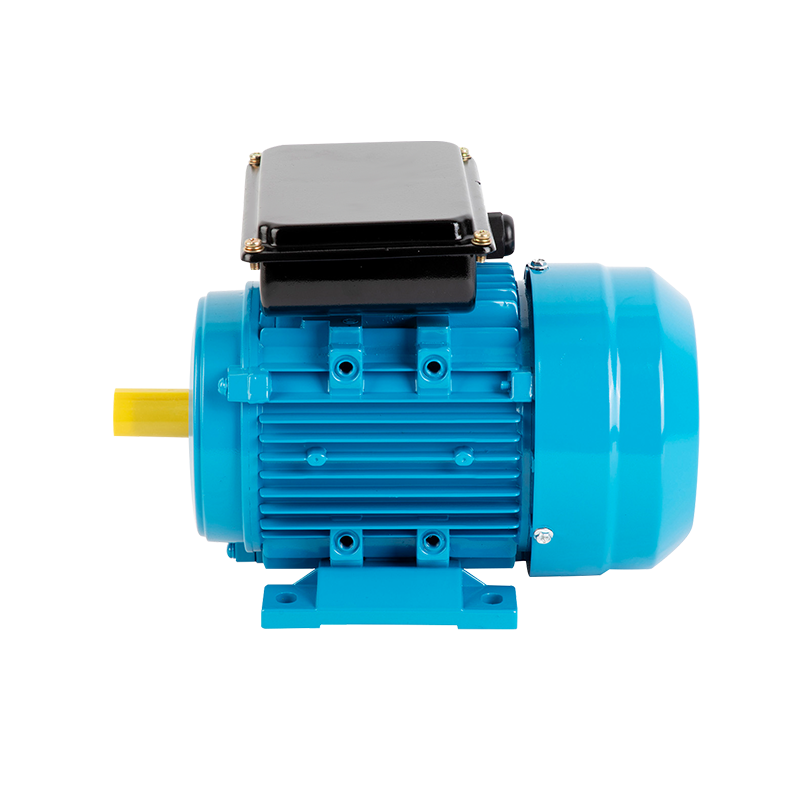

Cooling and Thermal Management

Heat is a major source of energy loss in motors. Efficient cooling systems, such as improved ventilation, heat sinks, or fan-assisted cooling, help maintainoperating temperatures. By reducing overheating, the motor experiences less resistance and consumes less energy. A Fan Motor Manufacturer often designs motors with better thermal management to sustain efficiency over extended operating periods, ensuring reliable performance while conserving power.

Maintenance and Longevity

Energy efficiency is also influenced by proper maintenance. Motors that accumulate dust or experience bearing wear can operate less efficiently. A Fan Motor Manufacturer may offer designs with sealed bearings, protective coatings, and easy access for maintenance to prolong motor life and maintain consistent energy performance. Regular upkeep ensures that the motor continues to run efficiently throughout its service life.

Fan motor manufacturers improve energy efficiency through a combination of design innovation, material selection, precision engineering, smart control systems, and effective thermal management. A Fan Motor Manufacturer that focuses on these areas can deliver motors that provide reliable airflow while consuming less energy. By adopting advanced technologies and thoughtful design practices, fan motors can meet performance demands while reducing operational costs and environmental impact. Choosing energy-efficient motors benefits both users and the broader effort toward sustainable energy use.