Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

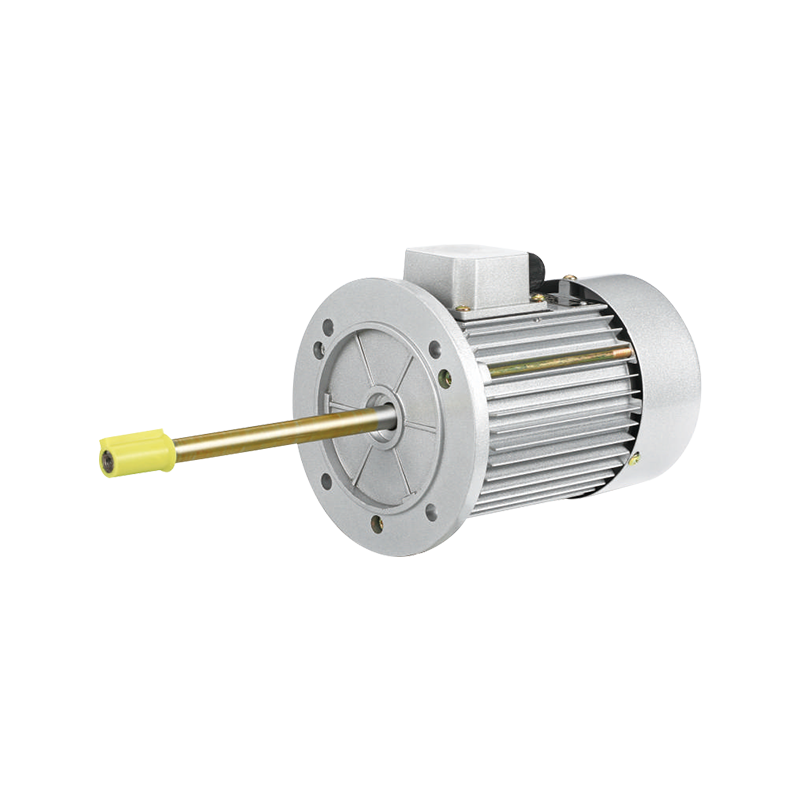

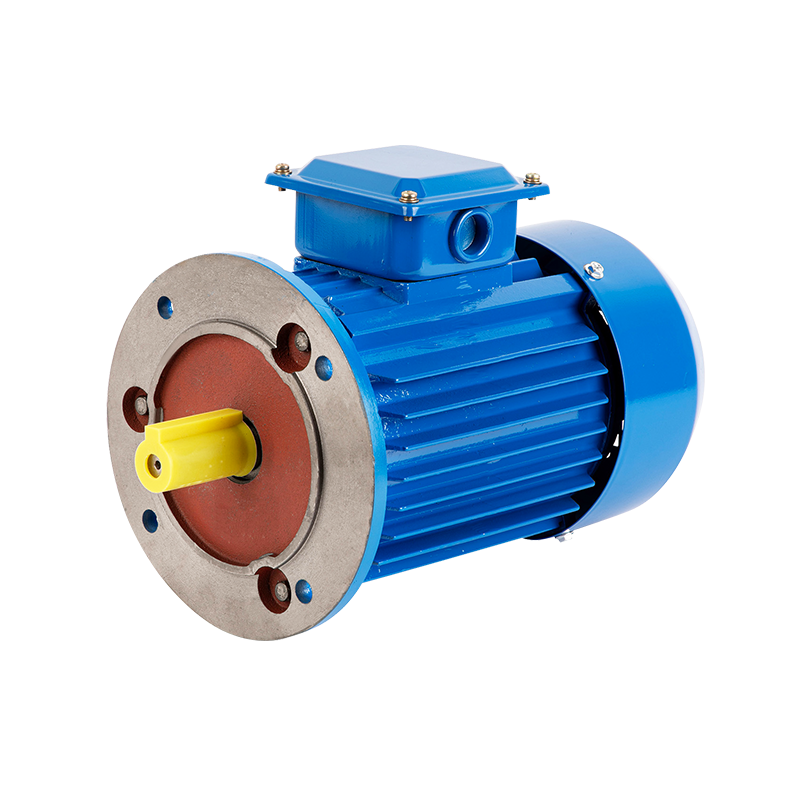

Vacuum pump motors are essential components in various industrial, laboratory, and manufacturing processes. They generate the suction necessary for applications such as vacuum forming, packaging, and chemical processing. Over time, like any mechanical or electrical device, a vacuum pump motor may experience wear or malfunction. A common question among users is whether a Vacuum Pump Motor can be repaired easily.

Common Issues Affecting Vacuum Pump Motors

Several factors can cause a vacuum pump motor to require maintenance or repair. Electrical issues such as worn-out brushes, damaged windings, or faulty capacitors can reduce motor efficiency or prevent it from operating entirely. Mechanical problems, including worn bearings, misaligned shafts, or debris in the pump chamber, can create noise, vibration, or decreased suction. Regular maintenance and inspection can identify these issues early, making the repair process simpler. A Vacuum Pump Motor that receives routine care typically experiences fewer severe failures and is easier to service.

Diagnosing the Problem

Accurate diagnosis is thestep in determining whether a vacuum pump motor can be repaired easily. Inspecting the motor visually for burnt components, corrosion, or physical damage can provide clues. Electrical testing, such as measuring resistance and continuity in the windings, helps identify internal faults. Mechanical assessment, including checking bearing play and shaft alignment, reveals wear or imbalance. A Vacuum Pump Motor that has been well-maintained may require only minor repairs, such as replacing bearings or brushes, which are relatively straightforward tasks for a skilled technician.

Repair Options

The ease of repairing a vacuum pump motor depends on the type and availability of parts. Common repairs include:

- Bearing Replacement: Bearings are among the frequently replaced components and can be swapped with standard tools if the correct replacement parts are available.

- Brush Replacement: For motors with carbon brushes, worn brushes can be replaced to restore functionality.

- Seal and Gasket Replacement: Leaks or worn seals can affect suction and are usually straightforward to replace.

- Electrical Component Repair: Damaged windings or capacitors may require specialized tools or rewinding services.

- A Vacuum Pump Motor designed with accessible components and widely available parts is generally easier and less time-consuming to repair.

Professional Service vs. DIY

While minor repairs can often be performed by trained personnel, more complex issues may require professional service. Rewinding a motor, diagnosing internal short circuits, or repairing severe mechanical damage typically demands specialized equipment and experience. Many users opt for service from certified repair centers to ensure the motor is restored safely and efficiently. A Vacuum Pump Motor that is serviced professionally may last longer and perform more reliably after repair than one repaired without proper tools or expertise.

Maintenance Tips to Simplify Repairs

Preventive maintenance can make future repairs easier and less costly. Regularly cleaning the motor, lubricating bearings, and checking electrical connections helps prevent common failures. Using the motor within recommended operating conditions, such as avoiding overheating or overloading, reduces wear and tear. Keeping records of maintenance and repairs also assists technicians in diagnosing issues quickly, improving repair efficiency for a Vacuum Pump Motor.

A vacuum pump motor can often be repaired, but the ease of repair depends on the nature of the problem, the design of the motor, and the availability of replacement parts. Routine maintenance, proper operation, and timely inspection can simplify repairs and extend the motor's service life. Whether through minor component replacement or professional servicing, a Vacuum Pump Motor can continue to perform effectively, ensuring reliable operation in a variety of industrial and laboratory applications.