Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

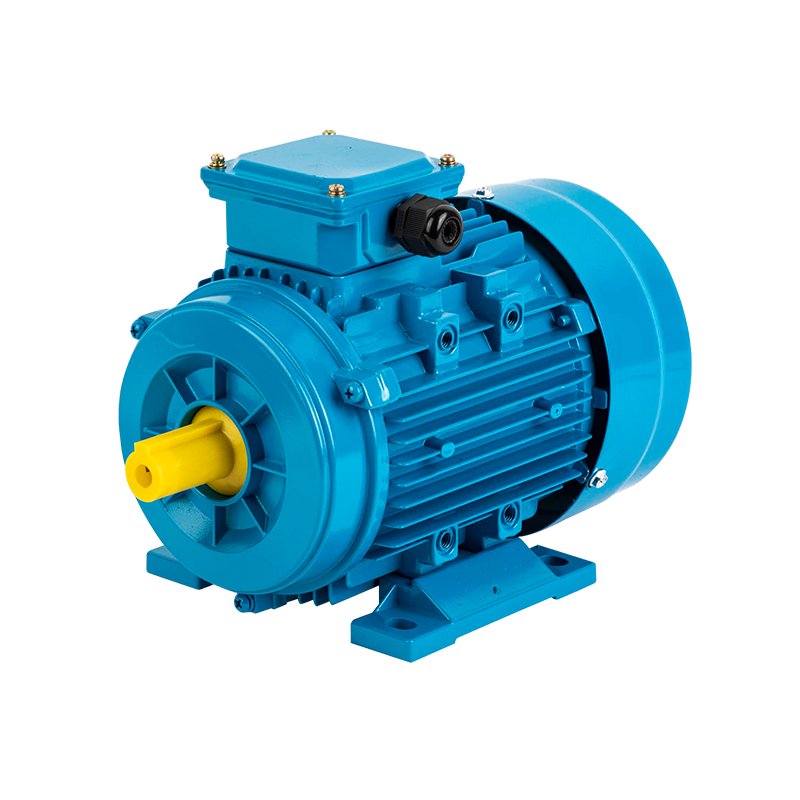

An AC Electric Motor Factory plays a critical role in producing motors that power a wide range of machines and devices. From household appliances to industrial machinery, AC electric motors are widely used due to their efficiency, reliability, and adaptability. Understanding how these factories operate, the materials they use, and the manufacturing processes involved can provide insight into the quality and performance of the motors they produce.

1. Core Manufacturing Processes in an AC Electric Motor Factory

An AC Electric Motor Factory typically involves several key stages: design, assembly, testing, and quality control. Each stage ensures that the motors meet specific electrical and mechanical standards.

- Design: Engineers plan the motor specifications, considering voltage, speed, and torque requirements.

- Material preparation: High-grade copper wires, laminations, insulation materials, and bearings are selected for durability and performance.

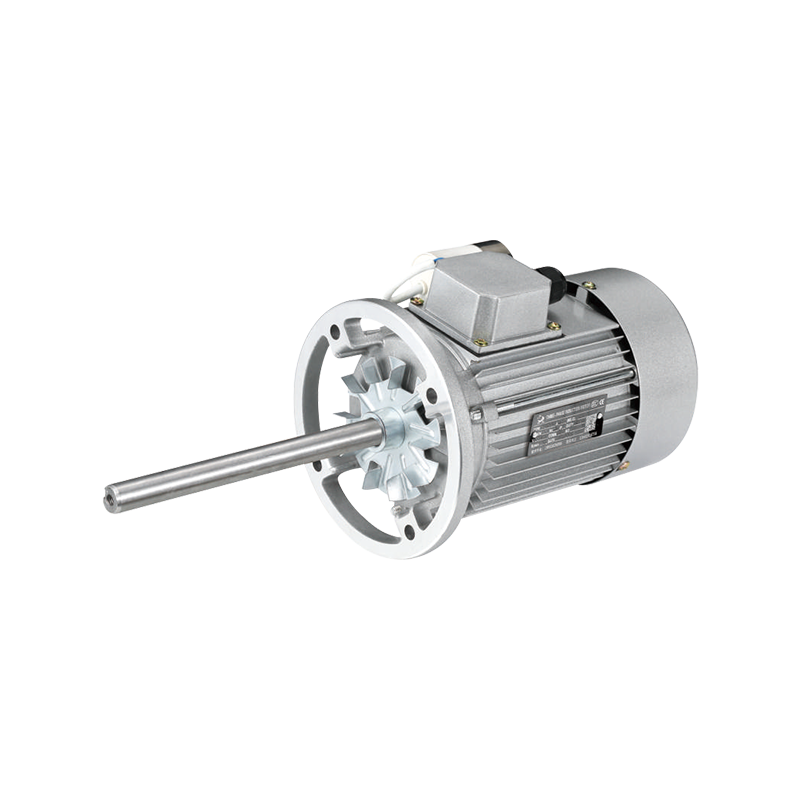

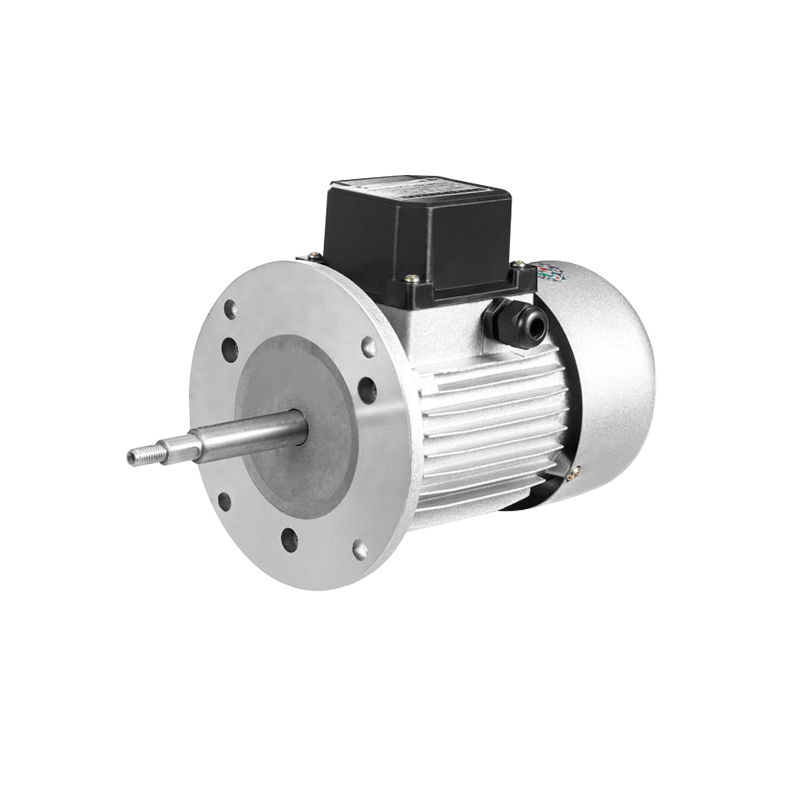

- Assembly: The stator, rotor, and other components are assembled with precision to ensure balanced operation.

- Testing and quality control: Finished motors are tested for efficiency, temperature rise, vibration, and noise levels to ensure they meet operational standards.

This structured process highlights the importance of meticulous production in an AC Electric Motor Factory.

2. Material Selection and Motor Durability

Materials used in AC electric motors determine their lifespan and efficiency. For instance, copper windings are commonly used for conductivity, while laminated steel cores reduce energy loss due to eddy currents. Bearings, insulation, and housing materials must withstand mechanical stress and environmental factors.

A high-quality AC Electric Motor Factory carefully selects these materials to ensure consistent performance. Proper material choice also reduces maintenance needs and helps motors operate reliably in diverse applications, from HVAC systems to conveyor belts.

3. Efficiency and Energy Considerations

AC electric motors are known for their ability to convert electrical energy into mechanical energy with minimal loss. Factories often implement processes that enhance efficiency, such as precise winding techniques, tight tolerances, and balancing rotors for reduced vibration.

Energy-efficient motors are increasingly in demand across industries due to rising electricity costs and sustainability initiatives. By producing motors that operate efficiently, an AC Electric Motor Factory contributes to reducing energy consumption in industrial and commercial settings.

4. Versatility and Application

Motors produced by an AC Electric Motor Factory are not limited to a single type of equipment. They are used in:

- Industrial machinery such as pumps, compressors, and fans

- Household appliances including washing machines and air conditioners

- Transportation systems like elevators and conveyor systems

- Renewable energy setups, including small wind and solar-driven machines

The factory's ability to produce motors of different sizes, speeds, and power ratings ensures they meet the diverse needs of multiple industries.

5. Maintenance and Quality Assurance

A significant aspect of an AC Electric Motor Factory is the emphasis on durability and serviceability. Factories may conduct accelerated life tests, insulation resistance measurements, and vibration analysis to detect potential weaknesses. These procedures help ensure that the motors have reliable performance and reduced downtime.

By maintaining high quality standards, the factory helps end-users benefit from equipment longevity, fewer breakdowns, and lower operational costs.

6. Technological Integration

Many AC Electric Motor Factories are adopting automation and smart production systems. Robotics, CNC machines, and digital monitoring allow for precise assembly and consistent output. These technologies also support scalability, enabling the factory to produce high volumes while maintaining uniform quality.

An AC Electric Motor Factory is essential for supplying efficient, durable, and versatile motors across multiple industries. Its combination of careful material selection, structured manufacturing processes, rigorous testing, and technological integration ensures that the motors meet practical and operational needs. By understanding the role and capabilities of such factories, businesses and consumers alike can appreciate the engineering and quality control that goes into producing reliable AC electric motors.