Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

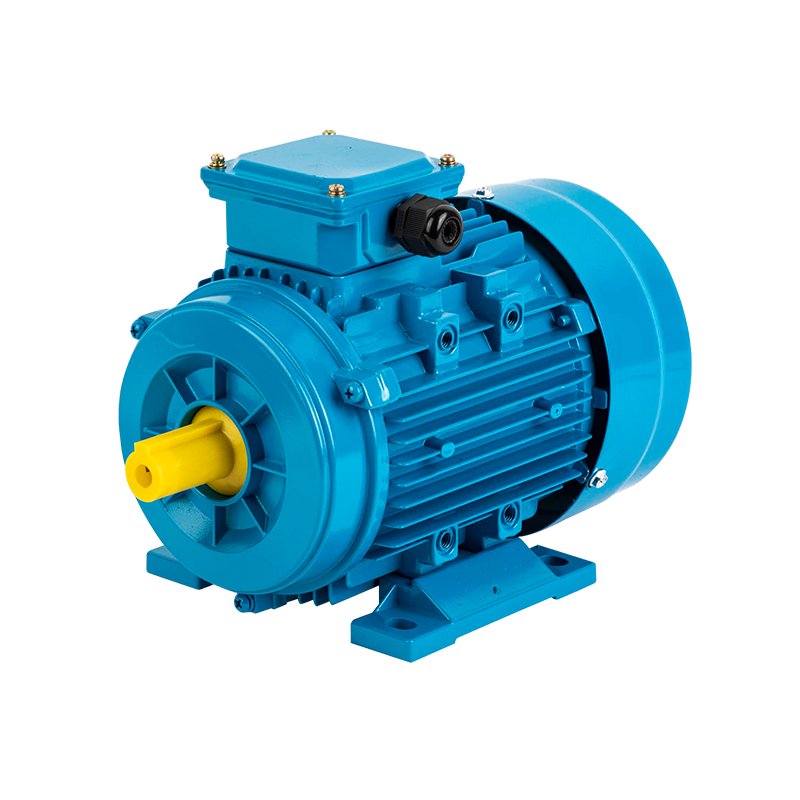

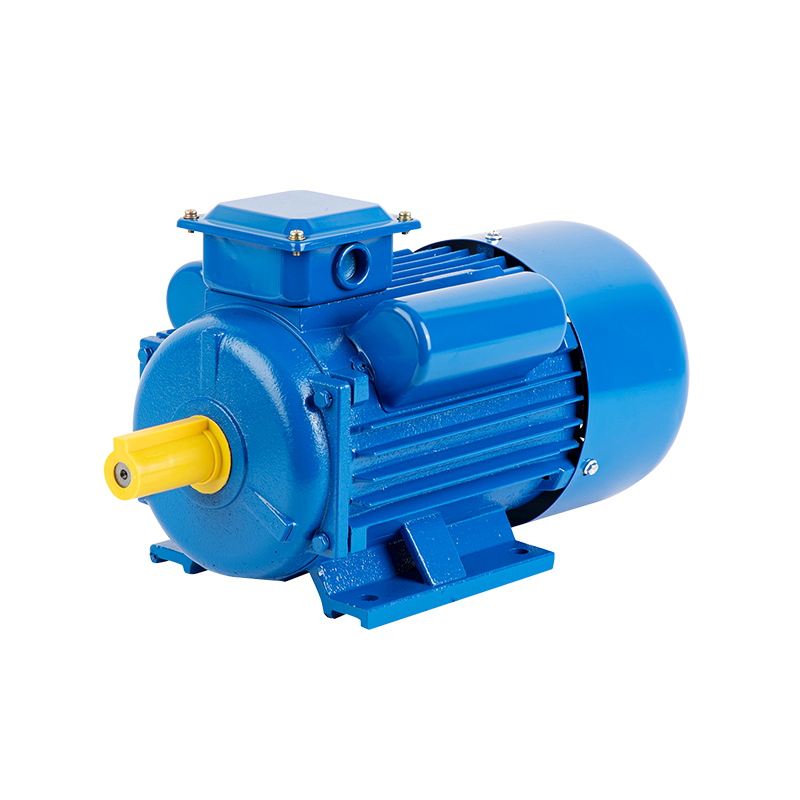

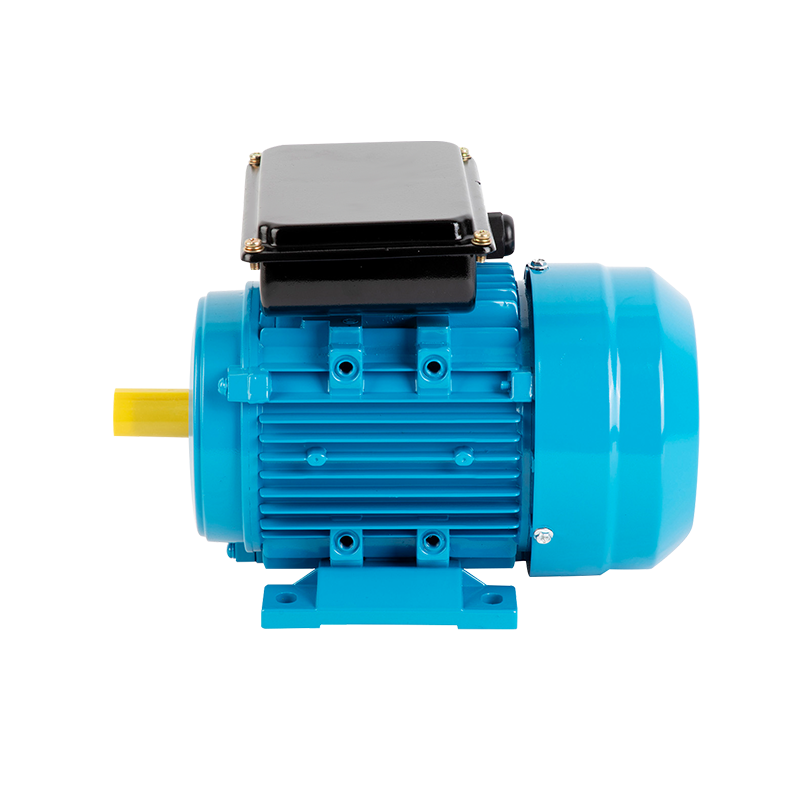

Three phase AC motors are widely used in industrial applications, ranging from conveyor systems to pumps, compressors, and HVAC equipment. Behind these motors are specialized Three Phase AC Motor Manufacturers, responsible for producing units that combine reliability, efficiency, and durability. Exploring the manufacturing process offers insight into how these motors meet the rigorous demands of modern industries.

1. Material Selection and Preparation

A Three Phase AC Motor Manufacturer starts with high-quality materials. The stator and rotor cores are typically made from laminated silicon steel sheets, selected for low energy loss and magnetic efficiency. Copper or aluminum windings are used depending on design requirements. Material preparation includes:

- Cutting and shaping steel laminations

- Insulating winding wires

- Verifying purity and mechanical properties

Careful material selection ensures the motor can withstand continuous operation and deliver consistent performance.

2. Winding and Core Assembly

The next critical stage for a Three Phase AC Motor Manufacturer is winding and assembling the core. Copper or aluminum wires are wound onto the stator slots with precise tension to prevent overheating or deformation. The rotor is then constructed with balanced laminations and conductors. Key points include:

- Accurate winding to reduce electrical losses

- Uniform insulation to prevent short circuits

- Mechanical balancing to reduce vibration

This stage determines the motor's efficiency, lifespan, and smooth operation.

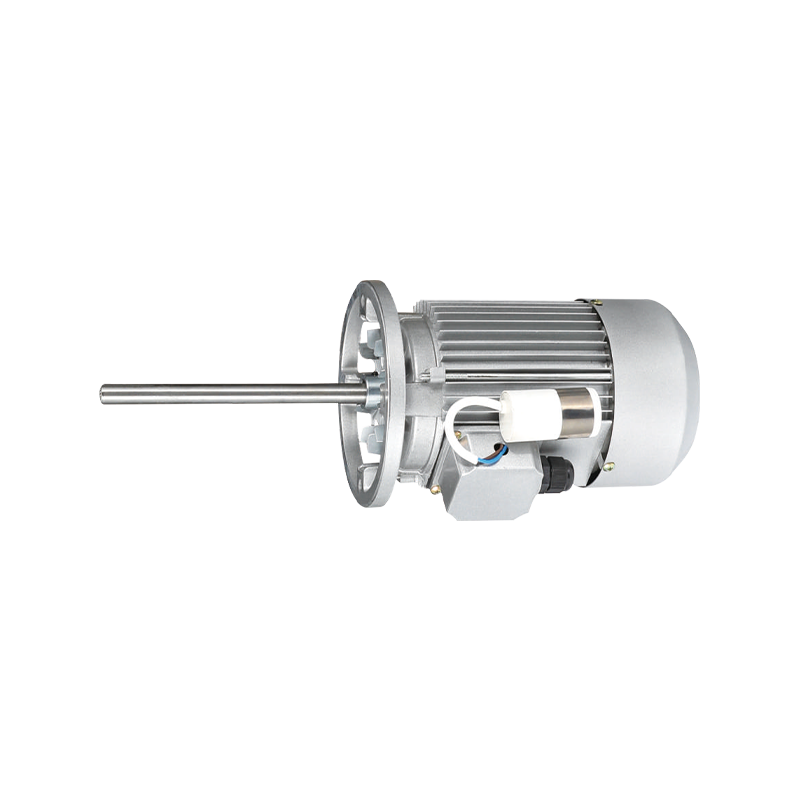

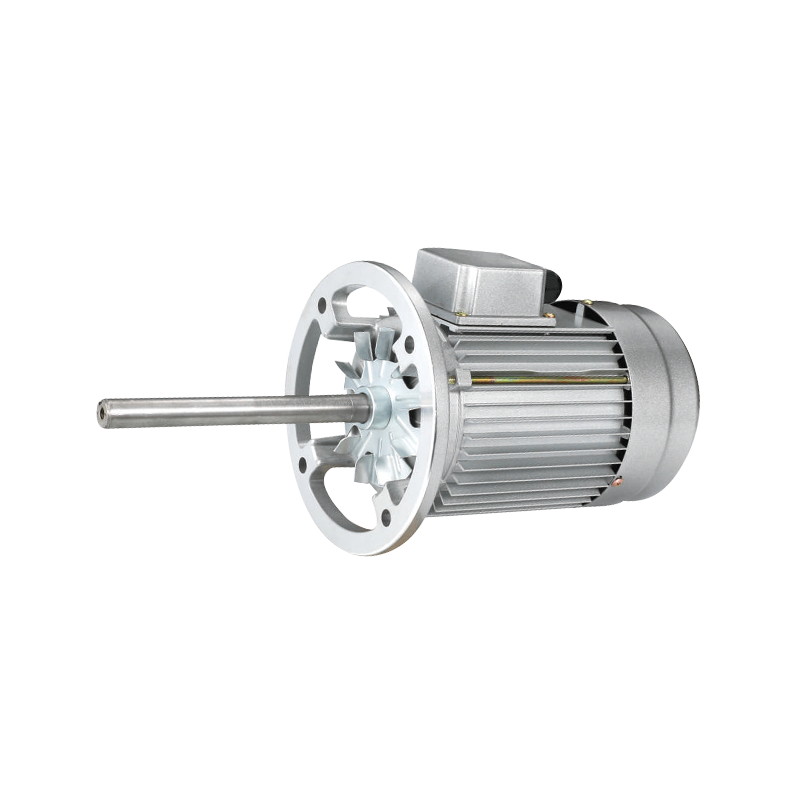

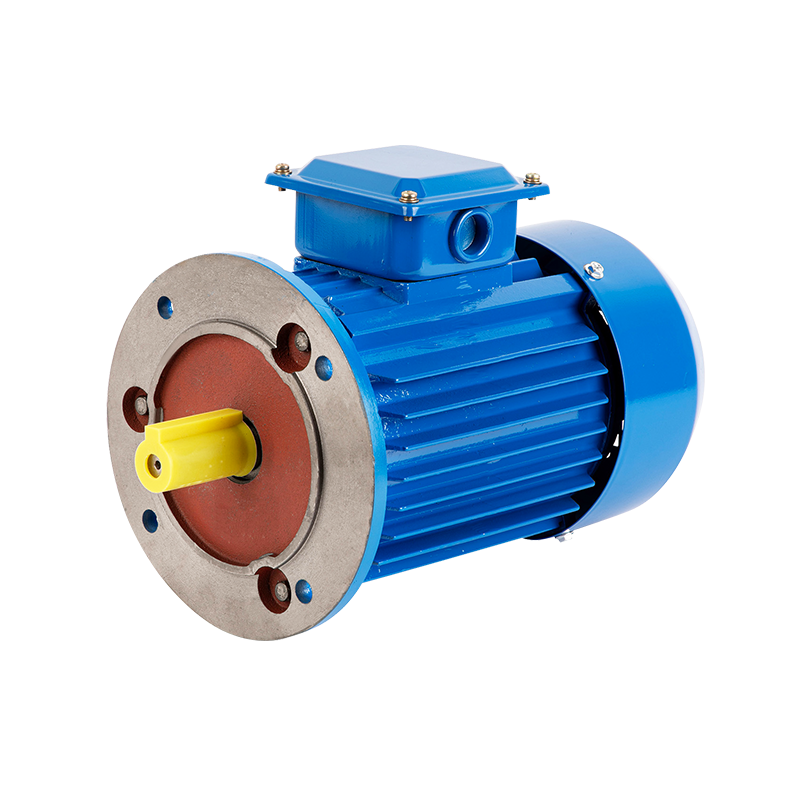

3. Motor Housing and Structural Assembly

Once the core is ready, a Three Phase AC Motor Manufacturer assembles the motor housing, including the end shields, bearings, and shafts. Housing materials are chosen for rigidity and heat dissipation. Bearings are carefully fitted to ensure low friction and stability. The assembly process includes:

- Aligning rotor and stator components

- Securing all mechanical parts

- Ensuring precise air gaps for magnetic efficiency

Proper assembly minimizes energy losses and mechanical wear during operation.

4. Testing and Quality Control

Quality assurance is a major focus for a Three Phase AC Motor Manufacturer. Completed motors undergo multiple tests to ensure compliance with specifications. Common tests include:

- Insulation resistance and dielectric strength tests

- Load and no-load performance checks

- Vibration and noise measurements

These checks ensure that each motor can operate reliably under industrial loads without overheating or mechanical failure.

5. Customization and Application Flexibility

Three Phase AC Motor Manufacturers often provide customization to suit different industrial needs. Variations in voltage, frame size, mounting style, and cooling methods allow motors to be adapted for:

- Conveyor and assembly lines

- Industrial pumps and compressors

- HVAC and ventilation systems

Customization enhances motor performance for specific applications and ensures compatibility with existing equipment.

6. Maintenance Considerations

Designing for easy maintenance is also part of a Three Phase AC Motor Manufacturer's process. Features such as removable end covers, standardized bearing sizes, and accessible terminals simplify routine inspection and repairs. Proper maintenance guidance helps end users extend the motor's operational life and maintain energy efficiency.

A Three Phase AC Motor Manufacturer combines careful material selection, precision winding, robust assembly, and thorough testing to deliver motors suitable for industrial demands. By offering customization and considering maintenance needs, these manufacturers ensure that their products provide reliable, efficient, and long-lasting performance. In an industrial environment, the role of a skilled motor manufacturer is essential for operational continuity and energy-efficient solutions.