Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

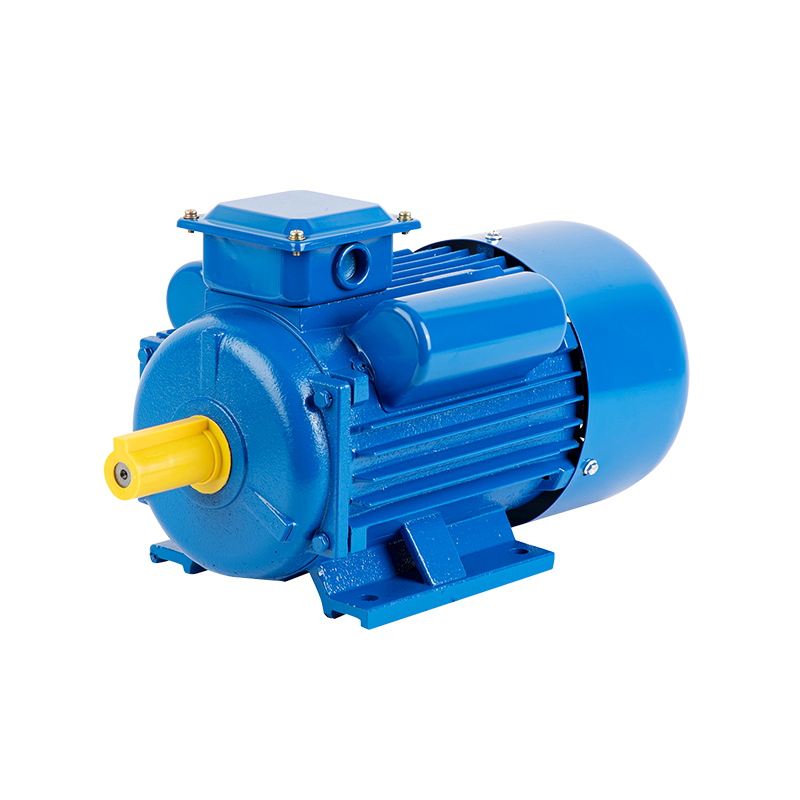

Industrial pump motors are essential components in many industrial systems, providing the necessary power to move fluids efficiently. Proper maintenance and timely troubleshooting are critical to ensure their reliability, longevity, and performance. This article addresses key questions related to maintaining and troubleshooting an industrial pump motor, offering practical guidance for operators and maintenance personnel.

How to Maintain an Industrial Pump Motor?

Regular maintenance is essential for the operation of an industrial pump motor. Routine tasks include cleaning the motor housing to prevent dust and debris accumulation, checking electrical connections for tightness, and ensuring that the motor is properly lubricated according to the manufacturer’s recommendations. Monitoring the motor’s operating temperature and vibration levels can help detect early signs of wear or imbalance. Additionally, ensuring that the pump is aligned correctly with the motor reduces stress on both components and improves efficiency. Scheduled inspections and preventive maintenance can significantly reduce the risk of unexpected failures and extend the service life of an industrial pump motor.

What Are the Common Problems of Industrial Pump Motors?

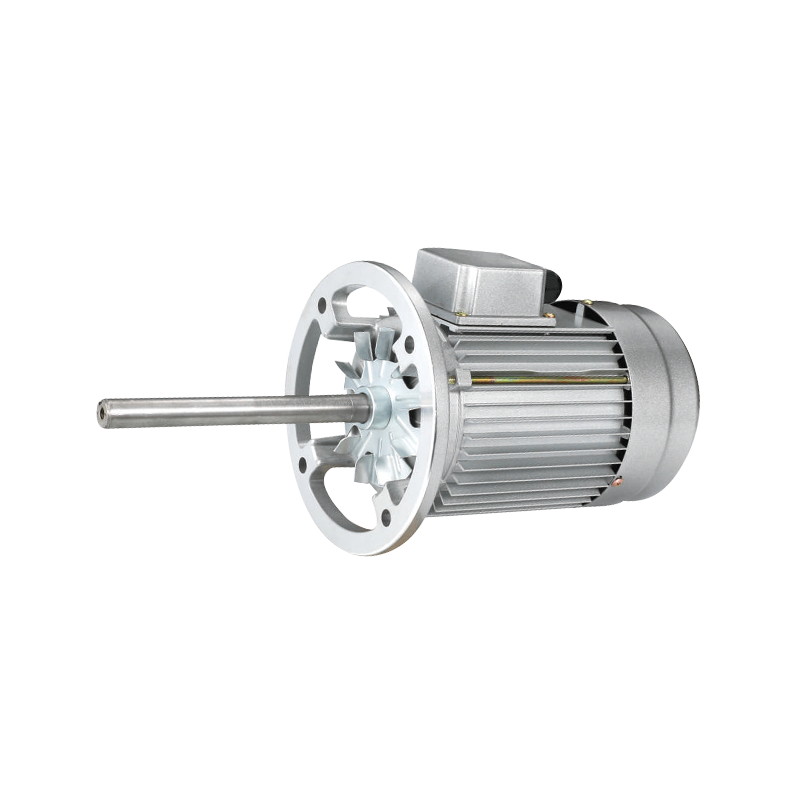

Industrial pump motors can encounter several common issues over time. One frequent problem is overheating, which may result from poor ventilation, excessive load, or electrical faults. Bearing wear is another common issue, often caused by insufficient lubrication or contamination. Misalignment between the pump and motor can to excessive vibration, noise, and premature component wear. Electrical problems, such as voltage fluctuations or insulation failure, can also affect motor performance. Recognizing these issues early is crucial for maintaining operational efficiency and preventing costly downtime.

How to Troubleshoot an Industrial Pump Motor?

Troubleshooting an industrial pump motor involves a systematic approach to identify and resolve issues. First, check the power supply to ensure the motor is receiving the correct voltage. Inspect electrical connections and control systems for any loose wires or signs of damage. Examine bearings, seals, and coupling alignment to detect mechanical problems. If the motor is overheating, verify that cooling fans and ventilation pathways are unobstructed. Vibration analysis and temperature monitoring can also help pinpoint problems. Following a structured troubleshooting process ensures that issues are addressed accurately and efficiently, minimizing the risk of repeated failures.

How Often Should Bearings or Seals Be Checked?

Regular inspection of bearings and seals is critical to the reliable operation of an industrial pump motor. Typically, bearings should be checked at intervals recommended by the manufacturer, which may range from every few months to annually, depending on operating conditions. Seals should also be inspected for signs of leakage, wear, or damage. Frequent monitoring helps prevent minor issues from developing into major failures, ensuring smooth operation and reducing maintenance costs. Proper lubrication and timely replacement of worn components are key factors in extending the life of an industrial pump motor.

Maintaining and troubleshooting an industrial pump motor requires consistent attention to detail and adherence to recommended procedures. By performing regular inspections, addressing issues promptly, and following proper maintenance schedules, operators can ensure that their industrial pump motors deliver long-term performance and efficiency.