Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

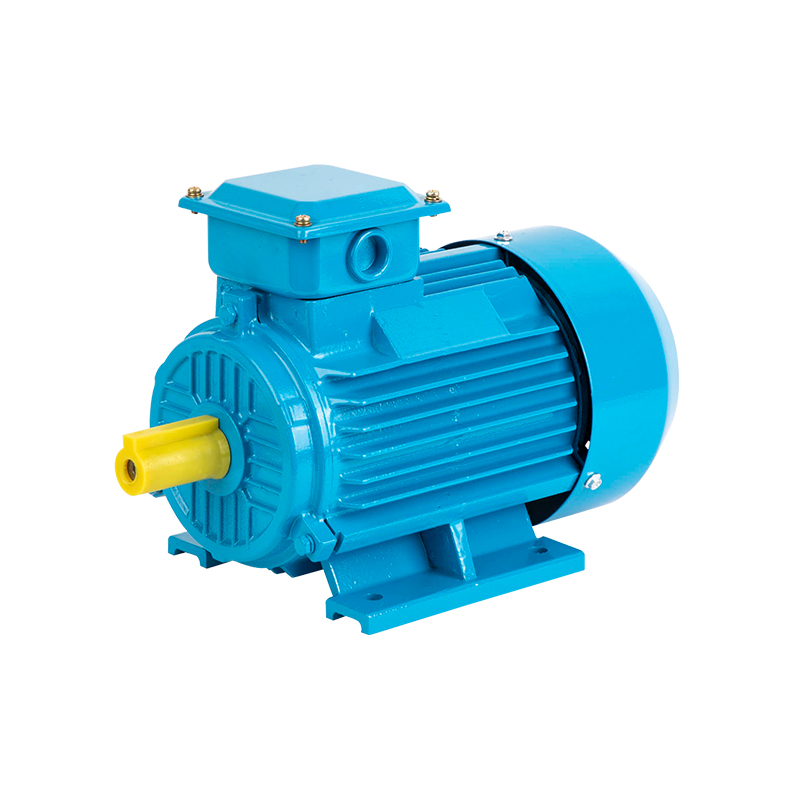

As industries across the globe continue to embrace the importance of energy efficiency, reliability, and cost-effectiveness, the Capacitor Run Asynchronous Motor has emerged as a crucial component in many applications. Known for its consistent performance and lower energy consumption compared to other motor types, the capacitor run asynchronous motor has garnered significant attention in sectors ranging from HVAC systems to manufacturing equipment. Its ability to provide torque, minimize power losses, and reduce operational costs makes it a preferred choice for businesses looking to optimize their machinery and reduce energy expenses.

What is a Capacitor Run Asynchronous Motor?

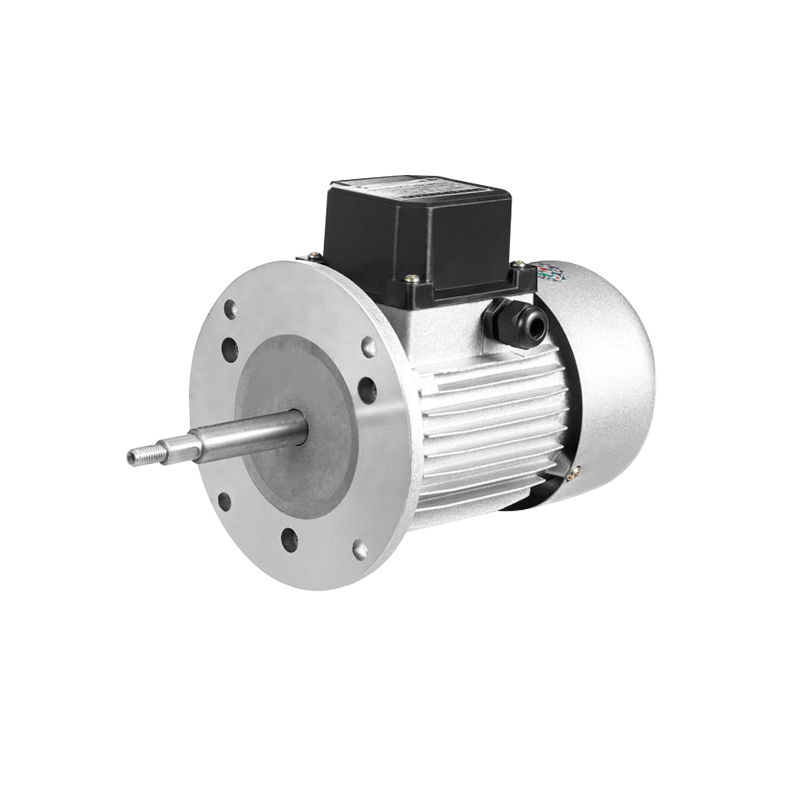

The Capacitor Run Asynchronous Motor is a type of induction motor that utilizes a capacitor to improve its performance, particularly during continuous operation. Unlike other types of induction motors that rely on a single-phase or three-phase power supply, a capacitor run asynchronous motor incorporates a capacitor in its circuit to help balance the current between the motor’s windings, resulting in a more efficient and stable operation.

The capacitor is connected in series with the motor’s windings to improve the motor’s power factor and efficiency, especially during the motor’s operation under load. This allows the motor to operate at a higher power factor than non-capacitor motors, meaning that it consumes less electrical energy to produce the same amount of mechanical output. The result is a smoother and more energy-efficient performance.

Key Advantages of Capacitor Run Asynchronous Motors

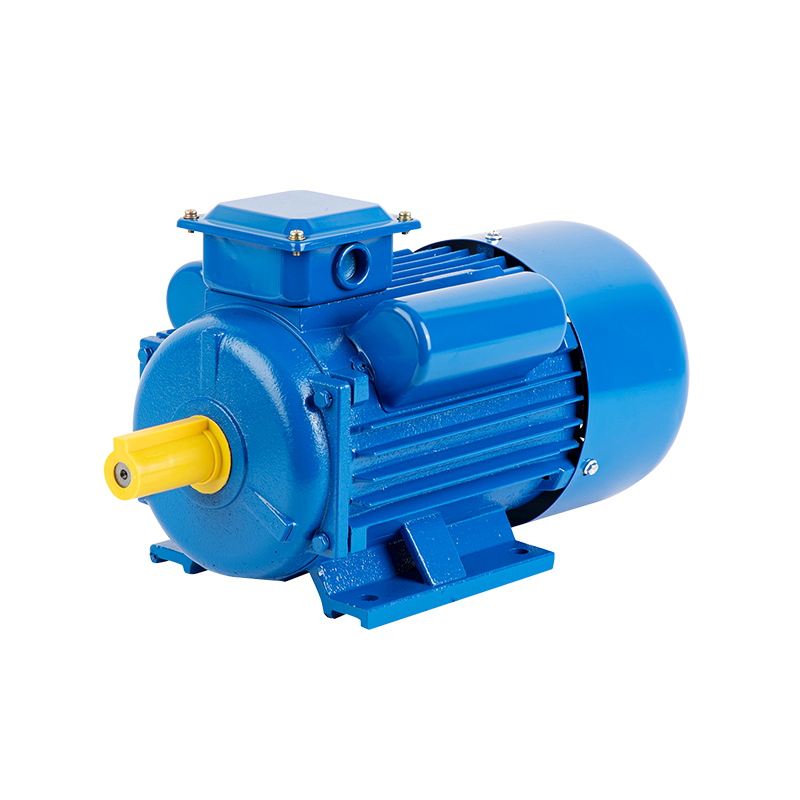

Enhanced Energy Efficiency: One of the primary benefits of Capacitor Run Asynchronous Motors is their energy efficiency. The capacitor helps to improve the motor's power factor by optimizing the current and voltage, which reduces wasted energy. This efficiency makes these motors particularly attractive for industries that operate continuously and require high energy performance, such as manufacturing plants, HVAC systems, and pump systems.

Consistent Torque and Stable Operation: Capacitor run asynchronous motors provide stable and consistent torque, which is essential for applications that require a steady and reliable power source. By minimizing fluctuations in the motor’s operation, these motors ensure that machines and equipment function smoothly over long periods without interruption.

Reduced Power Consumption: These motors are designed to consume less electrical power when compared to other types of motors. This is due to the capacitor’s role in improving the motor’s power factor and preventing excessive current draw. For industries looking to cut costs, the energy-saving potential of capacitor run motors makes them a highly cost-effective solution.

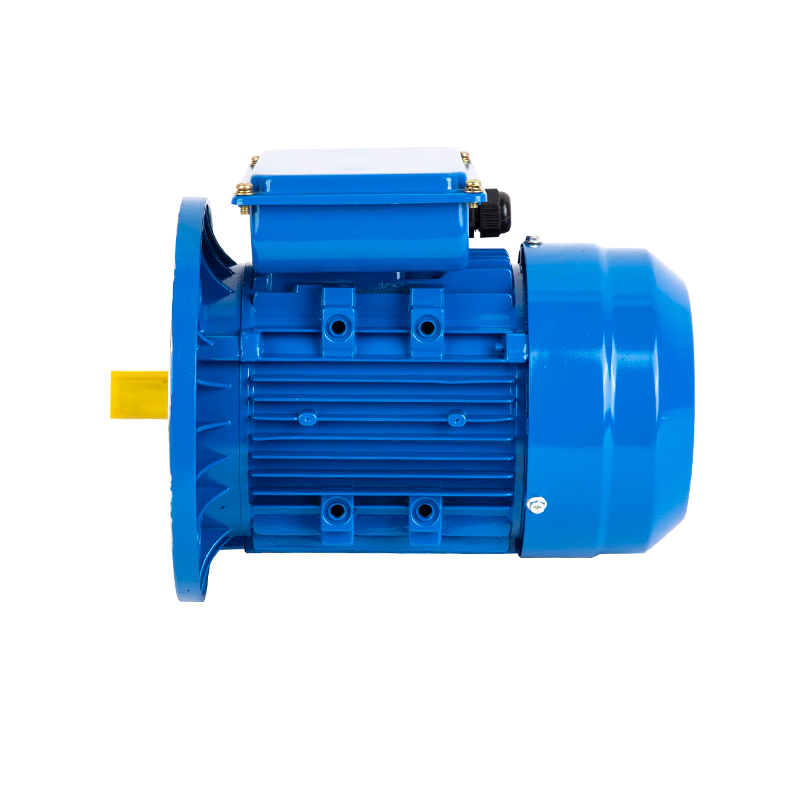

Better Starting and Running Performance: The inclusion of a capacitor allows for improved starting torque and running performance, particularly under load. This ensures that machines or devices connected to the motor can start and run smoothly without experiencing the sudden surge of energy that might occur in other types of motors. The motor’s ability to start quickly without significant power spikes is beneficial in applications like fans, pumps, and compressors.

Longer Lifespan and Reliability: Capacitor run asynchronous motors are typically built with durable materials that allow them to operate efficiently for extended periods. The stable and balanced operation of the motor reduces wear and tear, to fewer maintenance requirements and a longer operational lifespan.

Increasing Adoption in Industrial Applications

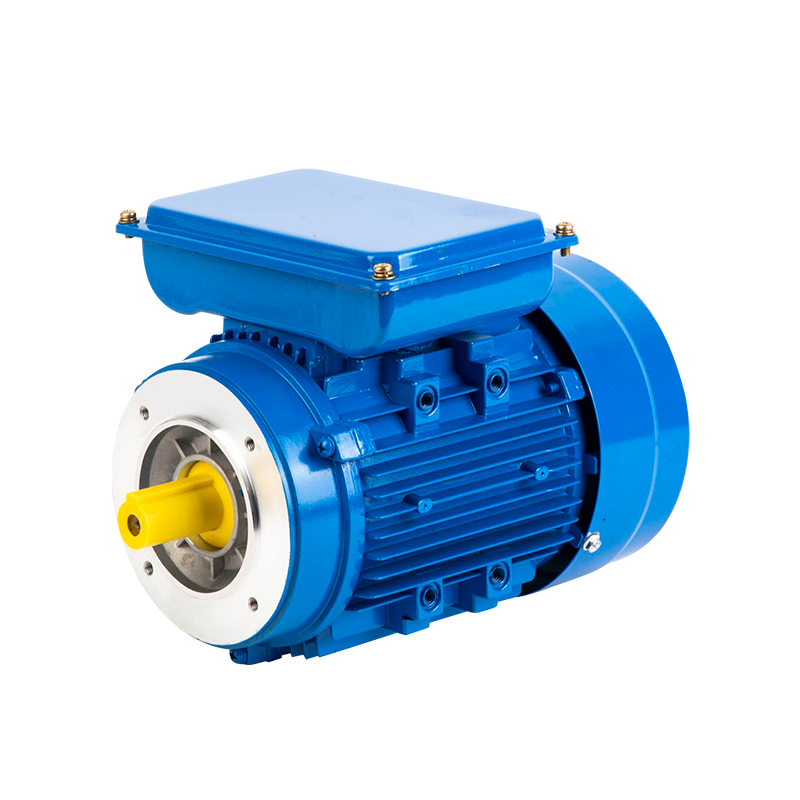

The demand for Capacitor Run Asynchronous Motors has increased steadily over the past decade, driven by the growing emphasis on energy efficiency and cost reduction in industrial applications. These motors are now widely used in industries ranging from HVAC (heating, ventilation, and air conditioning) to pumps, fans, compressors, and industrial machinery.

In HVAC systems, for instance, these motors are crucial in ensuring consistent airflow and energy savings. With their ability to deliver stable performance and consume less energy, capacitor run motors help reduce the overall energy consumption of heating and cooling systems, which operate for extended periods. The long-term energy savings make them a preferred choice for commercial buildings, hospitals, and other facilities that rely heavily on HVAC systems.

In manufacturing and process industries, these motors are used to power conveyor systems, mixers, and other equipment that require continuous and reliable operation. Their ability to provide consistent torque and minimize power consumption allows manufacturers to enhance productivity while reducing operating costs. This is particularly important in environments where operational downtime and energy costs can have a significant impact on a company’s bottom line.