Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

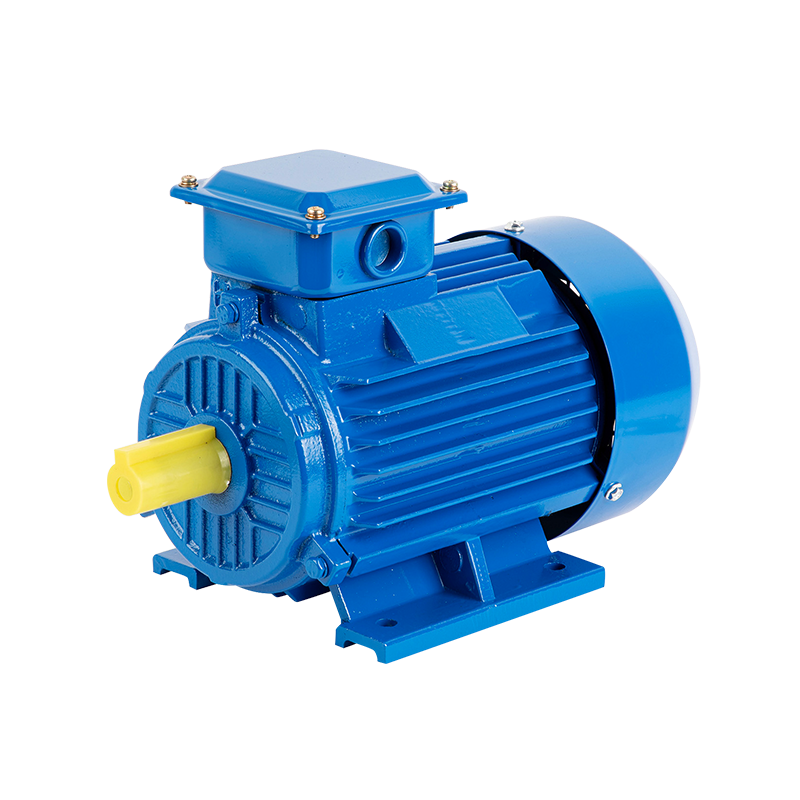

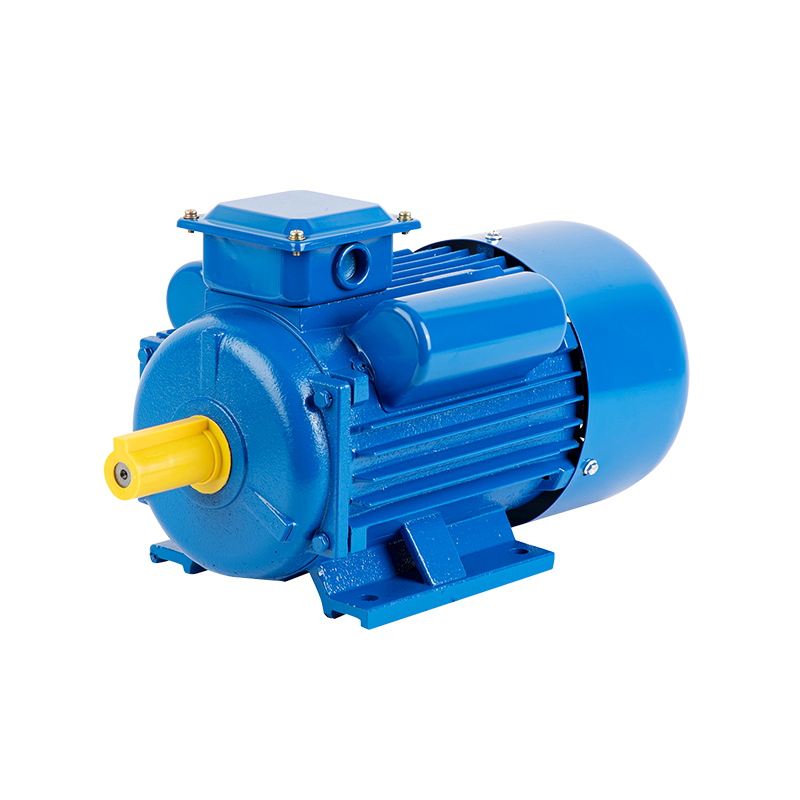

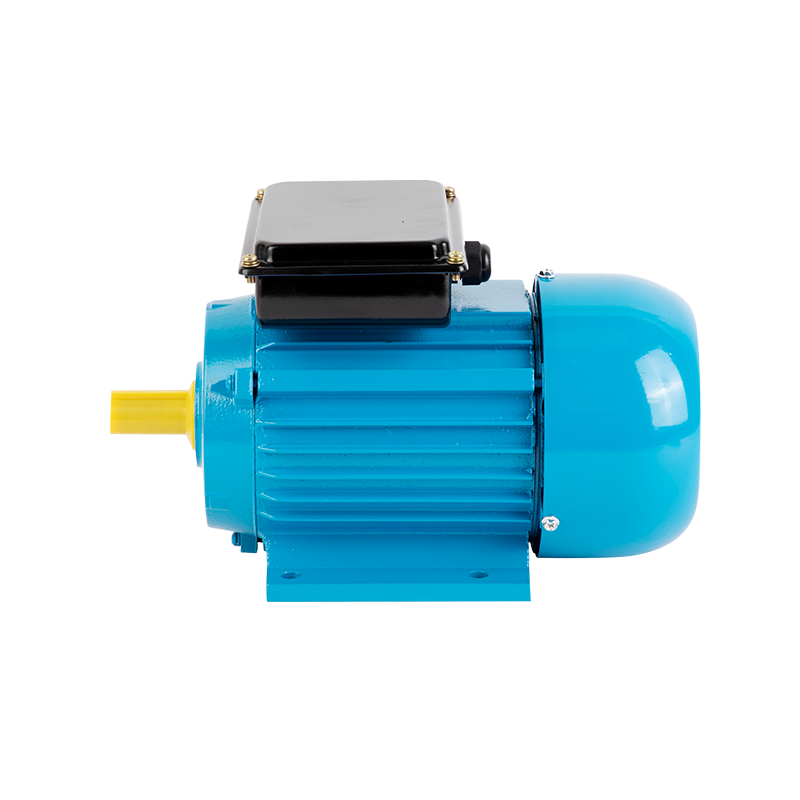

High efficiency electric motors have become increasingly important in modern industry due to their ability to reduce energy consumption and improve operational performance. These motors convert electrical energy into mechanical energy with minimal losses, making them suitable for a wide range of applications.

Industrial Applications

In industrial settings, high efficiency electric motors are widely used to power pumps, compressors, conveyors, and fans. These motors operate continuously under heavy loads, and improved efficiency can result in significant energy savings. For example, motors driving large pumps in chemical plants or water treatment facilities consume substantial electricity, and selecting high efficiency motors reduces operating costs while maintaining reliable performance. Factories and manufacturing facilities benefit from motors that maintain steady torque and speed under demanding conditions.

HVAC Systems

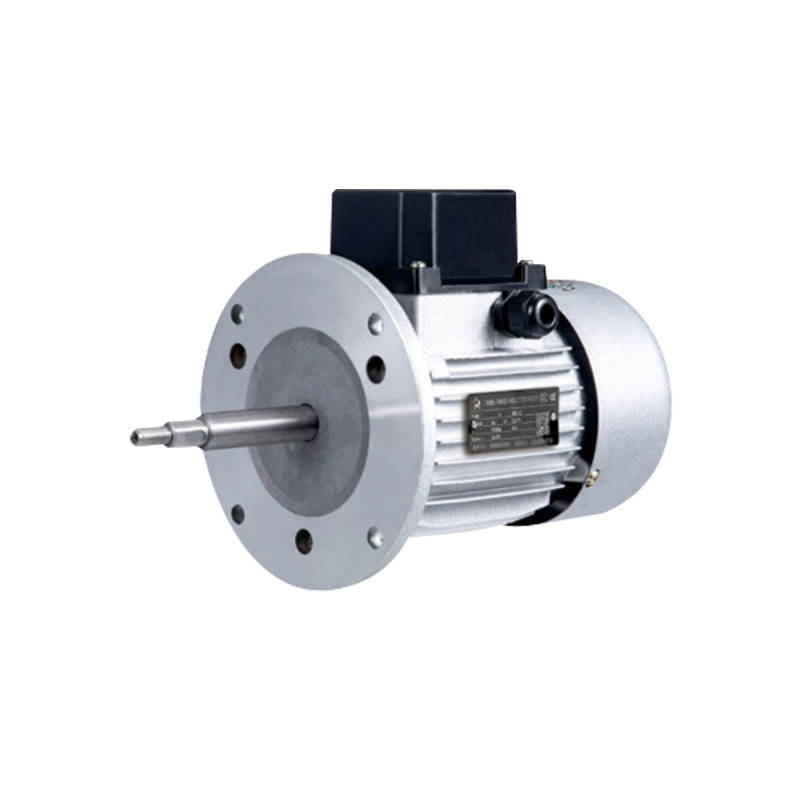

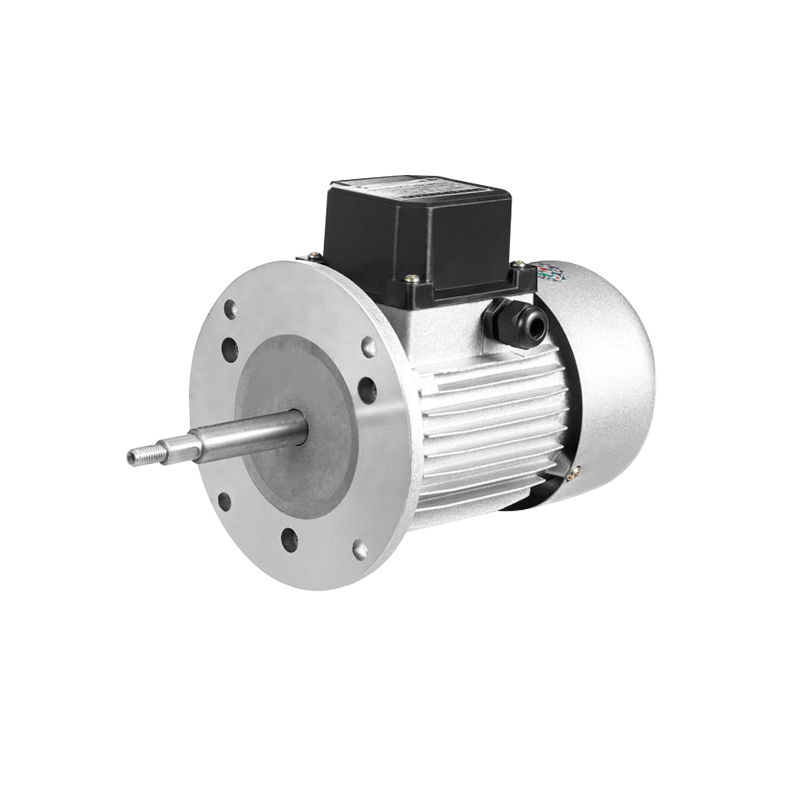

Heating, ventilation, and air conditioning (HVAC) systems often rely on high efficiency electric motors to drive fans, blowers, and compressors. These motors ensure consistent airflow and temperature control while minimizing electricity use. In commercial buildings, hospitals, and educational institutions, high efficiency motors reduce energy bills and contribute to environmental sustainability. They also improve system reliability, as efficient motors produce less heat, reducing wear and extending the life of components.

Agricultural and Water Management Uses

High efficiency electric motors are increasingly used in agriculture to drive irrigation pumps, grain elevators, and processing equipment. Efficient motors allow farmers to pump water or transport materials using less energy, which is particularly valuable in regions with limited electricity supply or high energy costs. Similarly, in municipal water management, these motors are used in wastewater treatment and water distribution systems to maintain steady operation while reducing energy consumption.

Renewable Energy Integration

Renewable energy systems, such as solar-powered or wind-powered pumping stations, benefit from high efficiency electric motors. These motors can operate effectively with variable power input, such as fluctuating solar panel output, while maintaining consistent performance. Using efficient motors ensures that renewable energy is utilized effectively, enhancing the sustainability and reliability of these systems.

Transportation and Mobility

High efficiency electric motors are also applied in transportation and mobility solutions, including electric vehicles, electric buses, and industrial electric forklifts. In these applications, motor efficiency directly affects battery life and range, making them a critical component for electric mobility. Efficient motors produce less heat and mechanical stress, contributing to longer operational life and improved performance under varying load conditions.

Maintenance and Longevity Considerations

High efficiency electric motors often require similar maintenance to standard motors but benefit from reduced operating temperatures and lower energy losses. Routine checks, lubrication, and monitoring for unusual vibration or noise are recommended. Because these motors generate less heat and mechanical stress, they tend to have longer service life, which can reduce maintenance frequency and overall lifecycle costs.

High efficiency electric motors are used across a variety of sectors, including industrial manufacturing, HVAC systems, agriculture, water management, renewable energy, and transportation. Their ability to convert electrical energy into mechanical energy with minimal losses causes to lower energy costs, improved reliability, and longer operational life. Selecting the right high efficiency electric motor for a specific application ensures better performance, energy savings, and sustainability in both commercial and residential settings.

By understanding the applications and benefits, engineers and decision-makers can implement high efficiency electric motors to improve operational efficiency, reduce environmental impact, and support long-term energy management goals.