Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

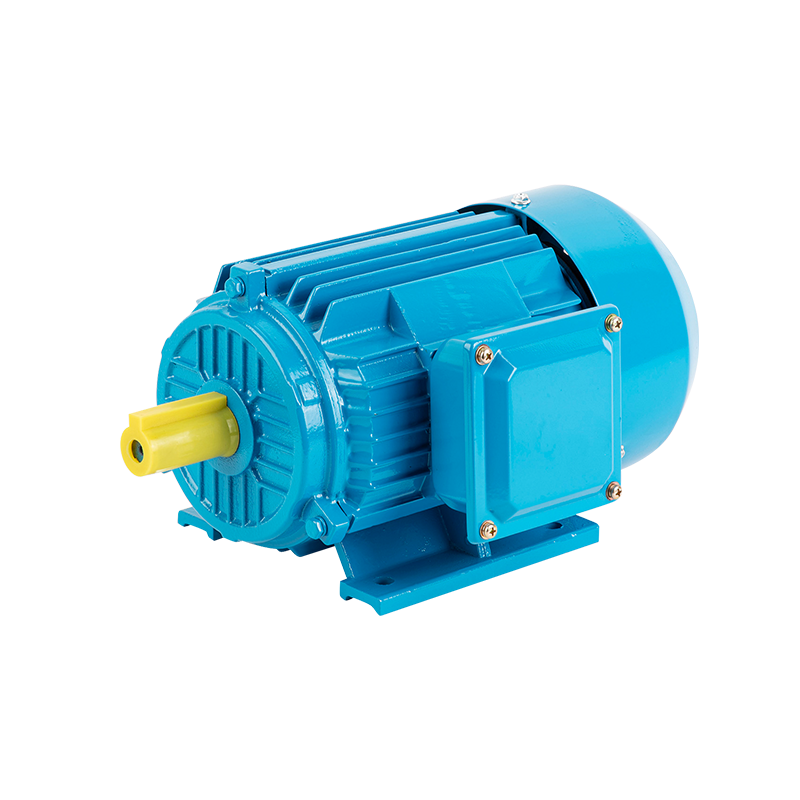

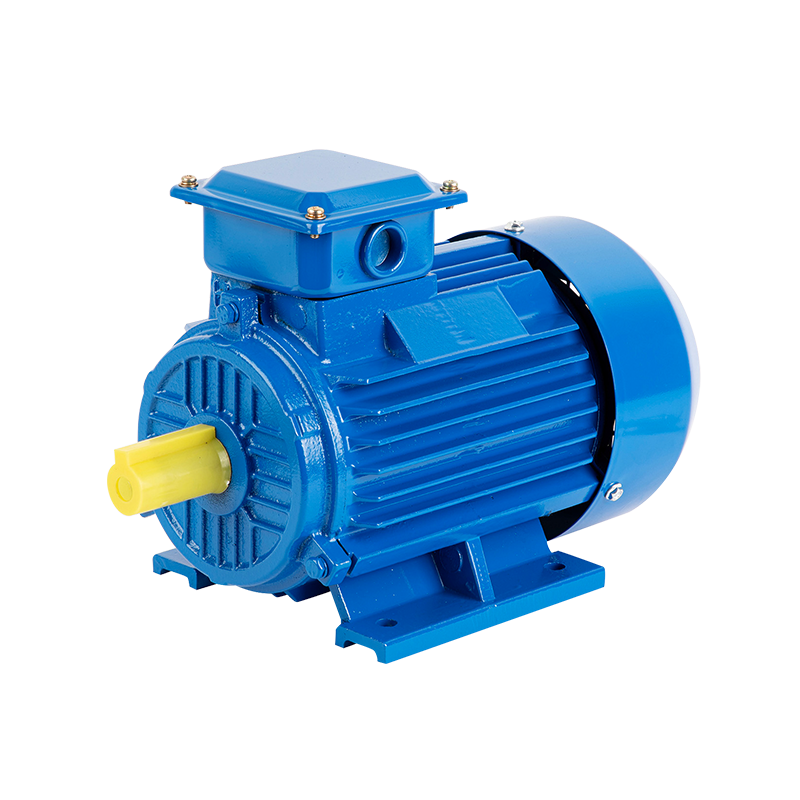

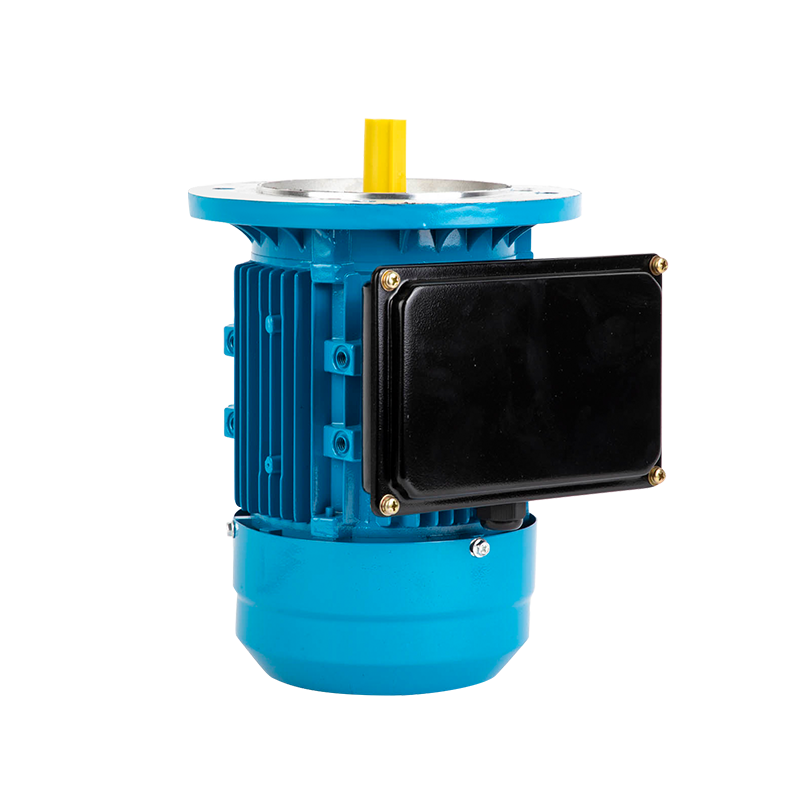

Three-phase AC motors are widely used in industrial machinery, manufacturing lines, pumps, and HVAC systems. Selecting a reliable Three Phase AC Motor Manufacturer is essential to ensure product consistency, efficiency, and durability. By understanding the production process, quality control measures, and customization options, businesses can make informed decisions and reduce operational risks.

Material Selection and Components

A critical step in manufacturing is choosing the right materials. A Three Phase AC Motor Manufacturer typically uses high-grade copper or aluminum for windings, durable steel for rotors, and reliable insulation materials that can withstand heat and electrical stress. The quality of these materials directly affects motor efficiency, longevity, and performance under continuous load conditions. Additionally, the selection of bearings and shafts is carefully considered to minimize friction and vibration.

Precision Manufacturing Processes

The production process involves multiple stages, including stator winding, rotor assembly, and balancing. A Three Phase AC Motor Manufacturer often employs automated machinery to ensure precision in every unit. Proper alignment of components and accurate winding techniques are crucial for reducing energy loss and vibration. Advanced molding and coating methods may also be used to improve insulation and protect the motor from environmental factors such as humidity or dust.

Quality Control and Testing

Quality control is a major focus for any reputable Three Phase AC Motor Manufacturer. Motors are tested for electrical performance, noise, vibration, thermal stability, and efficiency. Units that fail to meet standards are corrected or rejected to maintain product consistency. This careful testing ensures that motors can handle industrial workloads without unexpected breakdowns and meet regulatory or client requirements.

Customization and Technical Support

Some Three Phase AC Motor Manufacturers provide customized solutions based on voltage, frame size, cooling method, or operational environment. Customers can request adaptations to suit specific machinery or industrial processes. Alongside customization, technical support and maintenance guidance are often offered. This support helps integrate motors smoothly into existing systems and ensures reliable long-term operation.

Energy Efficiency Considerations

Energy efficiency is increasingly important in industrial applications. Motors designed by a Three Phase AC Motor Manufacturer may feature energy-saving designs that reduce electricity consumption and heat generation. Efficient motors not only lower operational costs but also extend the life of connected equipment by maintaining stable performance under load.

Applications Across Industries

Three-phase AC motors are used in a variety of industrial settings, including conveyor systems, pumps, compressors, HVAC units, and production machinery. Selecting a reliable Three Phase AC Motor Manufacturer ensures that these motors provide steady performance, improve operational stability, and contribute to workplace safety. Manufacturers capable of producing both standard and customized units are particularly valuable for complex industrial applications.

Choosing a Three Phase AC Motor Manufacturer requires attention to material quality, precision in production, rigorous testing, and technical support. A reliable manufacturer ensures that motors deliver consistent performance, long service life, and energy-efficient operation. By understanding these factors, businesses can select the right partner to meet their industrial motor needs while maintaining smooth and efficient operations.