Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

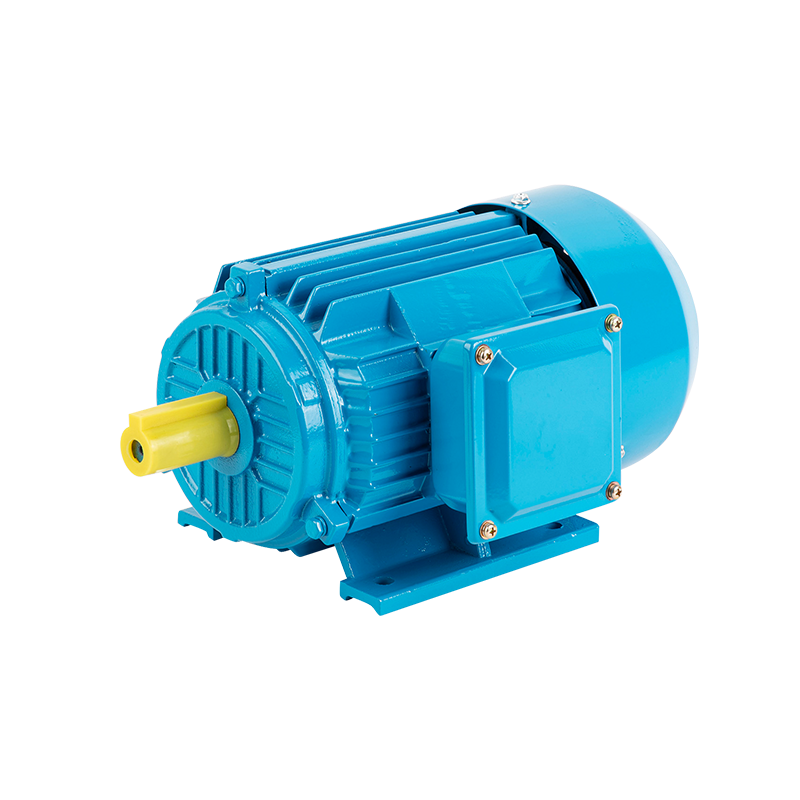

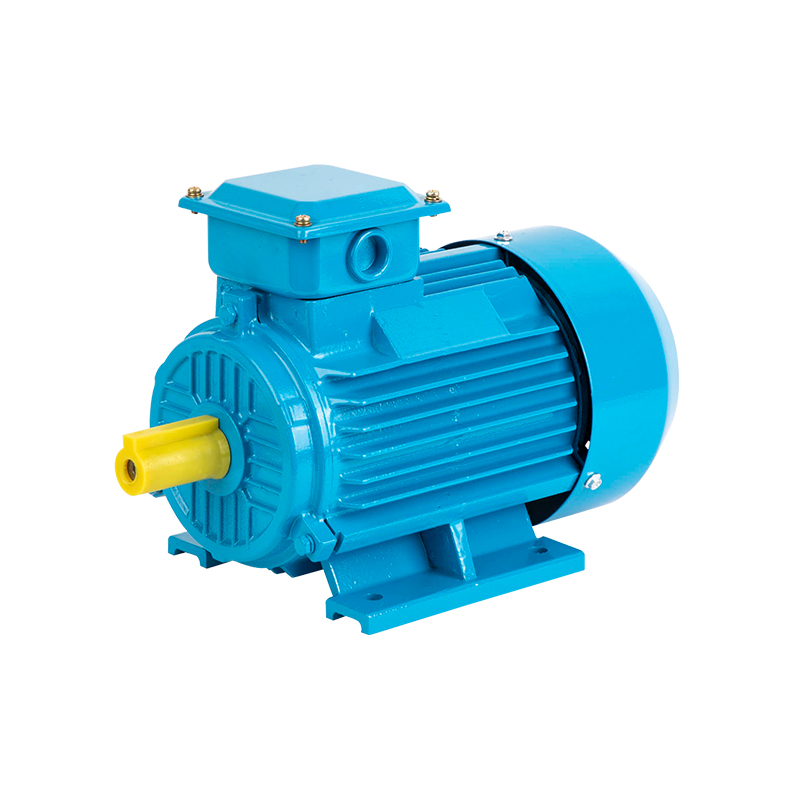

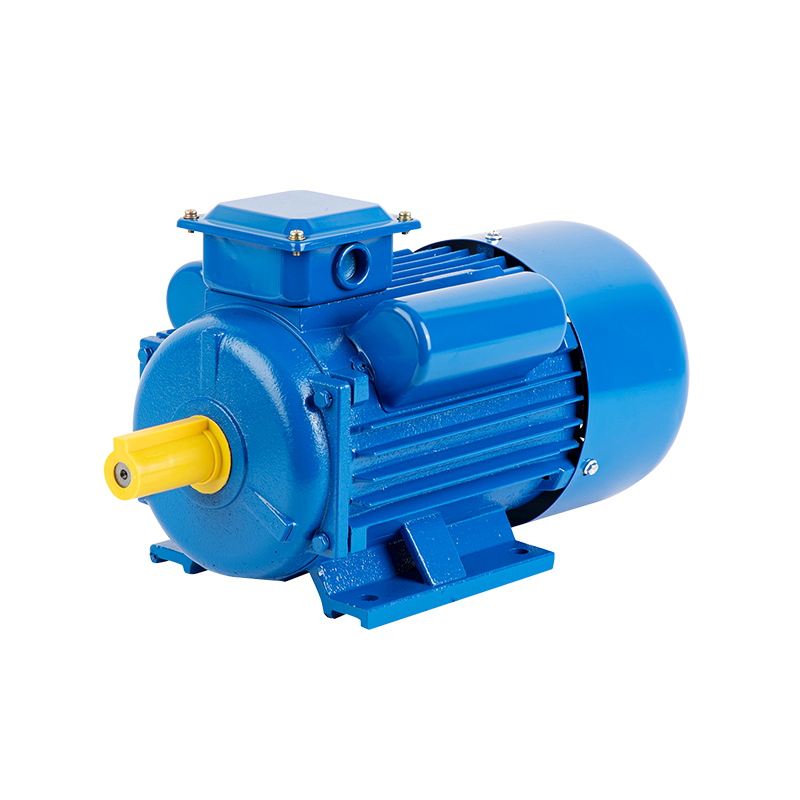

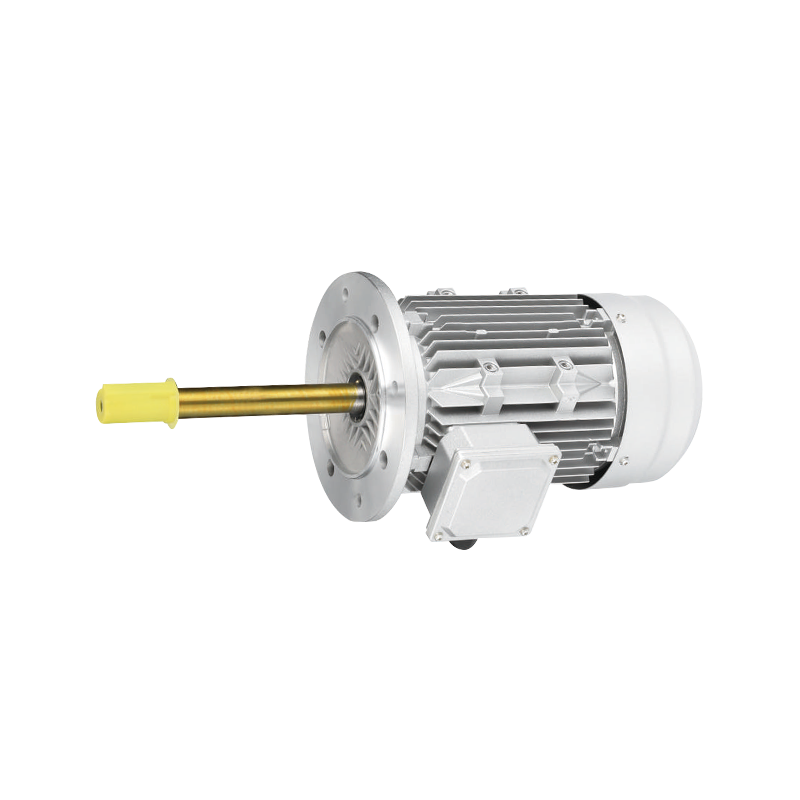

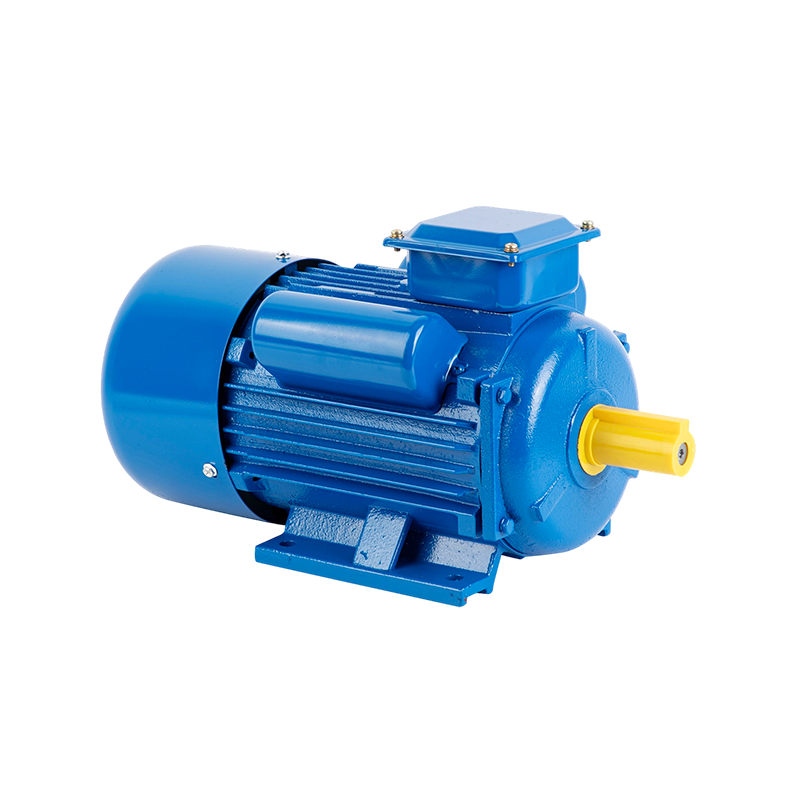

AC electric motors are widely used in industries ranging from manufacturing to HVAC systems and household appliances. To ensure reliability and efficiency, these motors are carefully produced in specialized facilities. An AC Electric Motor Factory is where raw materials, engineering expertise, and quality control come together to create products that meet industrial and commercial requirements.

Raw Material Selection

The production of an AC motor starts with selecting the right materials. An AC Electric Motor Factory relies on high-quality copper for windings, steel for laminations, and durable insulation materials. The quality of these components directly affects the motor's performance, thermal management, and lifespan.

Factories usually perform inspections on incoming materials to prevent defects and ensure consistency. Even minor deviations in metal composition or insulation thickness can reduce efficiency or cause early failure.

Assembly Process

The assembly process in an AC Electric Motor Factory involves multiple precision steps:

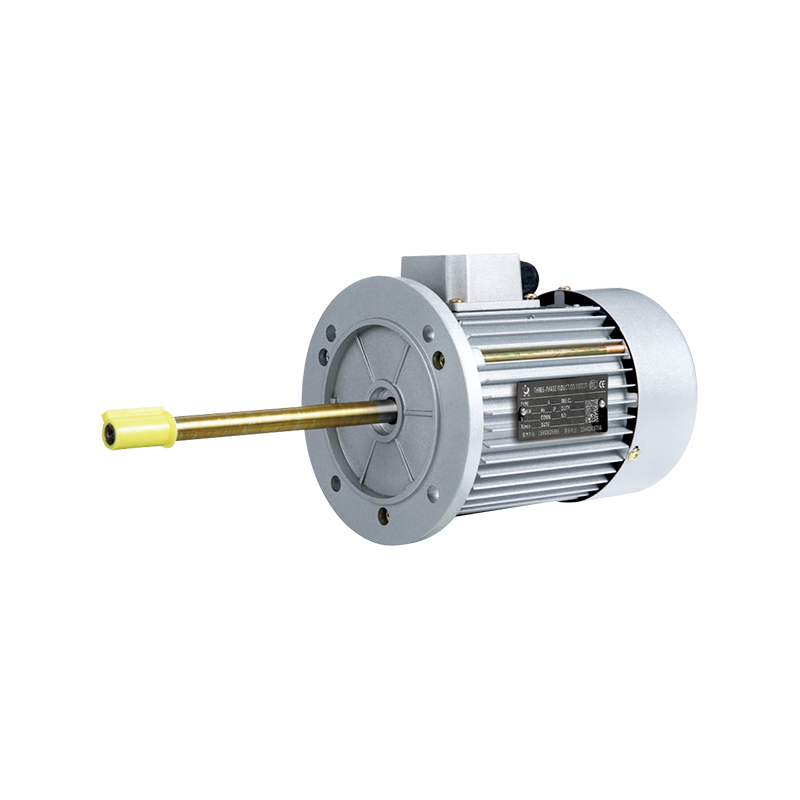

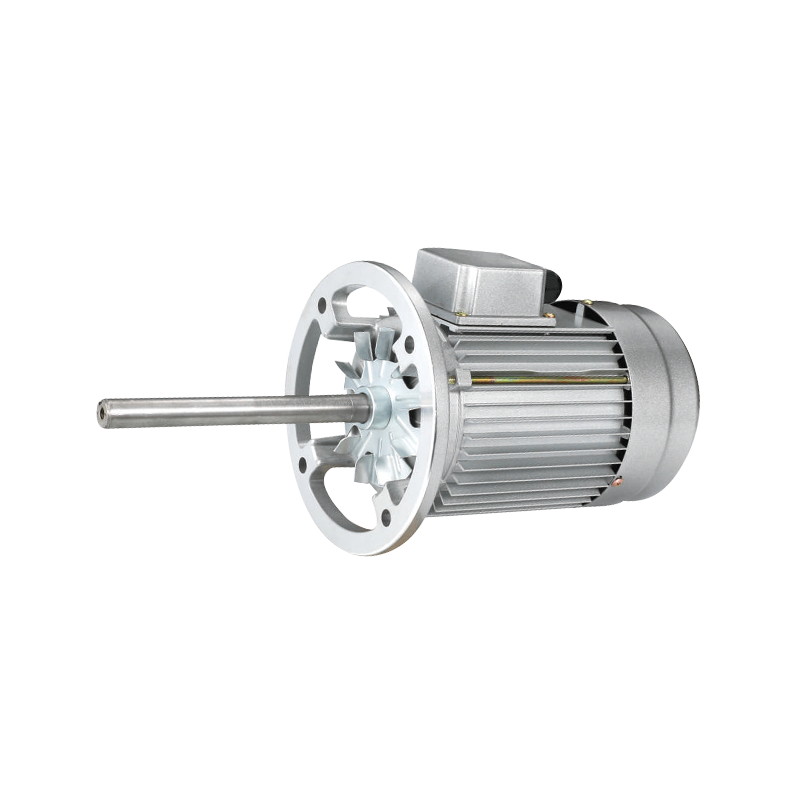

- Stator and Rotor Construction: Laminated steel cores are stacked, and windings are applied. Insulation and varnishing are added for electrical safety.

- Rotor Installation: The rotor is fitted carefully into the stator to maintain balance and prevent vibration during operation.

- Frame and Housing Assembly: Protective casings are added to enclose the motor, securing internal components.

- Electrical Connections: Wiring and terminals are connected, often with semi-automated machinery for consistent accuracy.

Each stage is designed to reduce errors and ensure that every motor leaving the factory meets technical specifications.

Testing and Performance Verification

Quality control is critical in an AC Electric Motor Factory. Motors undergo rigorous testing to confirm both electrical and mechanical performance. Standard tests may include:

- Measuring insulation resistance and dielectric strength

- Checking torque, rotation speed, and load performance

- Vibration and noise analysis

- Heat tolerance and thermal stability assessment

These tests ensure that the motor performs reliably in industrial or commercial applications, giving buyers confidence in long-term use.

Applications of AC Motors

Motors from an AC Electric Motor Factory are versatile and used across multiple sectors. They power pumps, compressors, conveyor systems, industrial machinery, and HVAC units. For industrial buyers, understanding the production process helps match motor specifications to operational needs, ensuring efficiency and reducing maintenance costs.

Factors Buyers Should Consider

When sourcing from an AC Electric Motor Factory, buyers often evaluate:

- Manufacturing capacity and delivery times

- Range of motor types and available customizations

- Testing and compliance certifications

- Support services, including maintenance guidance

- Production efficiency and process consistency

Choosing a reliable factory helps maintain smooth operations and reduces risks associated with motor failures or replacements.

Efficiency and Environmental Considerations

Modern AC Electric Motor Factories increasingly focus on sustainability. Efficient assembly lines, waste recycling, and energy-conscious production reduce environmental impact. Producing motors that comply with energy efficiency standards is another consideration for factories serving clients in regulated industries.

An AC Electric Motor Factory is more than a manufacturing site—it is where engineering, material science, and quality assurance converge to produce reliable motors. From raw material inspection to assembly and performance testing, every step influences the final product's durability and efficiency. For businesses and industrial buyers, understanding these processes is essential for selecting the right supplier, ensuring motor reliability, and supporting operational continuity.