Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

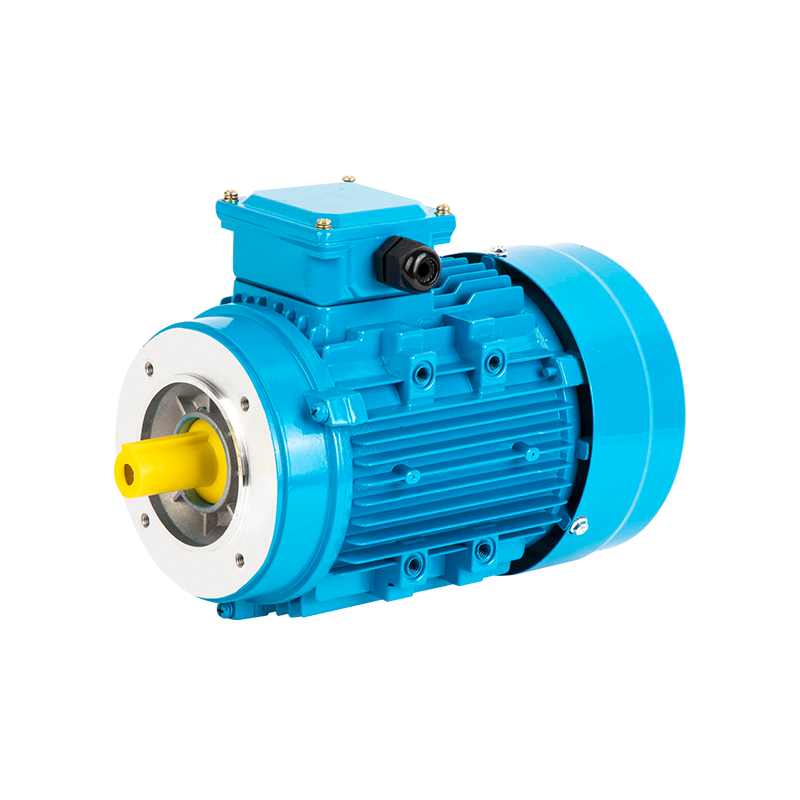

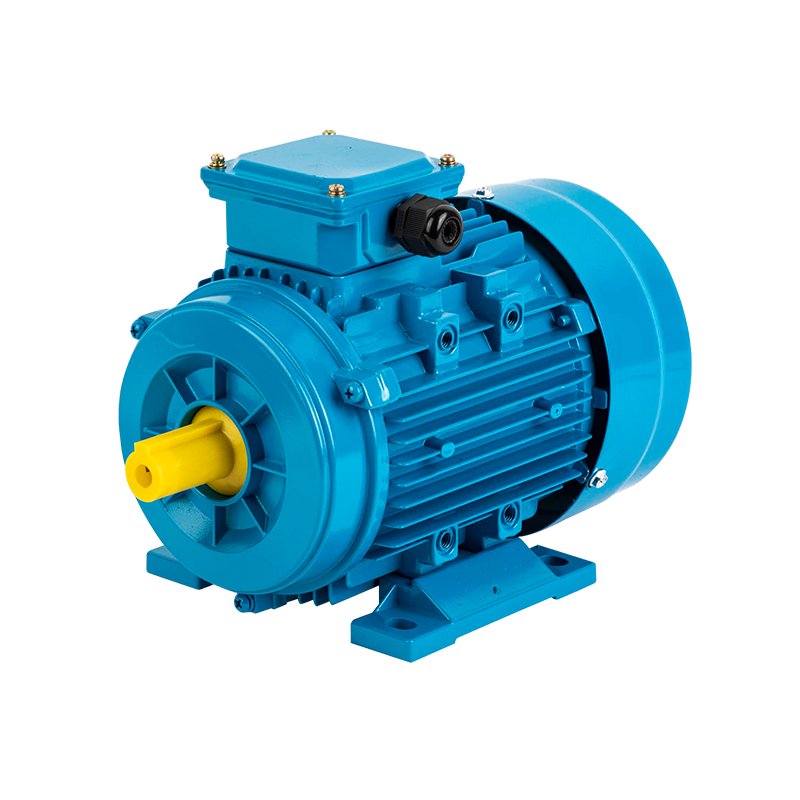

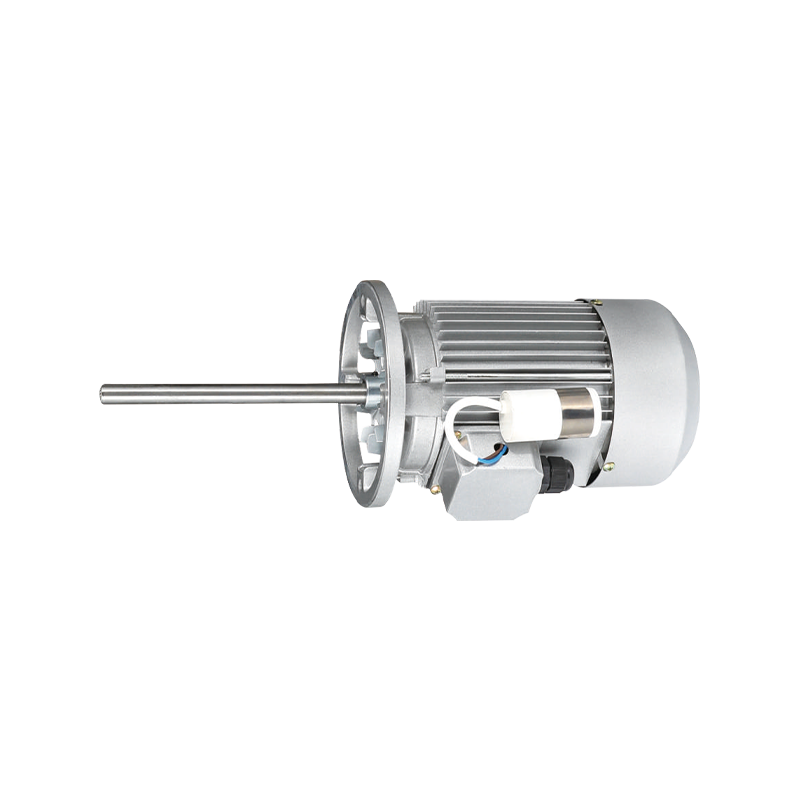

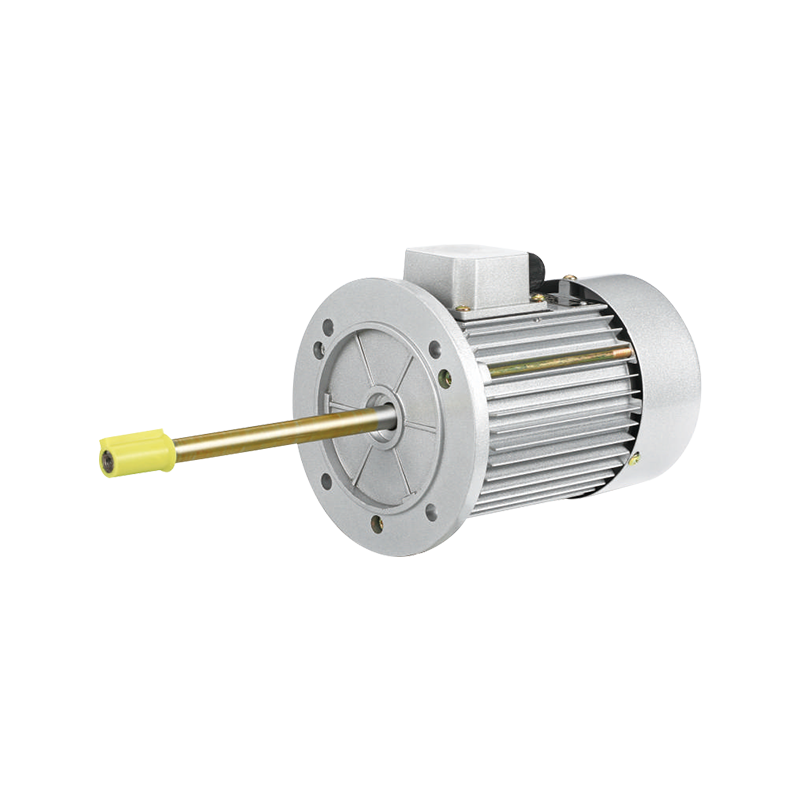

An AC Electric Motor is a widely used device in industrial, commercial, and domestic applications. Its primary function is to convert electrical energy into mechanical energy, providing motion for pumps, fans, conveyors, and machinery. Understanding its features, design, and applications helps buyers and engineers select the right motor for specific needs.

Construction and Design

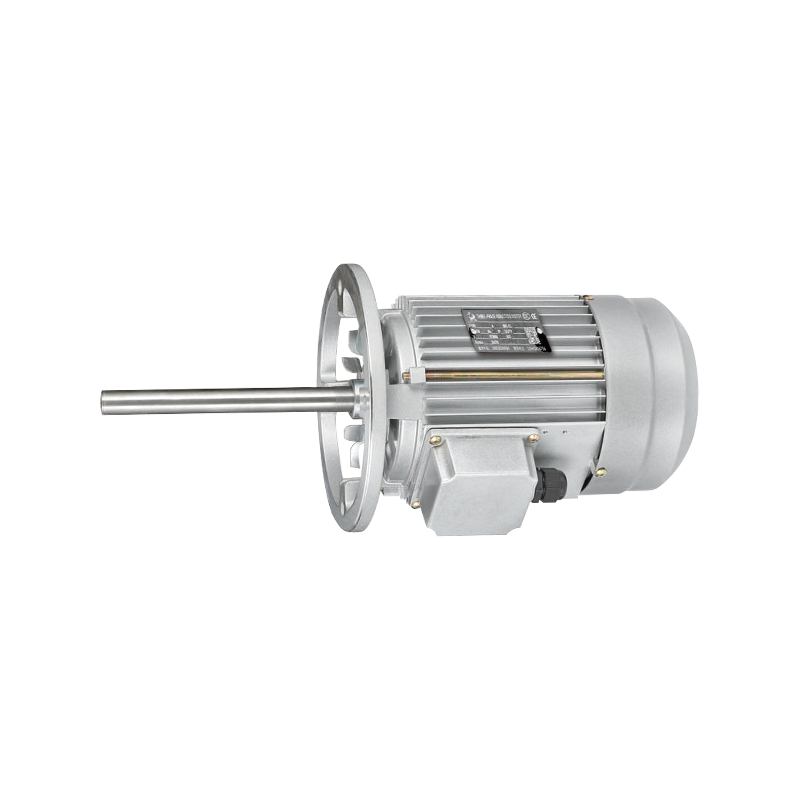

The construction of an AC Electric Motor typically includes a stator, rotor, bearings, and housing. The stator generates a rotating magnetic field, while the rotor responds to this field to produce motion. Quality manufacturers ensure precise alignment of components, which improves performance and reduces wear over time.

Cooling systems, such as ventilated housings or external fans, are integrated into many AC electric motors to prevent overheating during long operational hours. These design choices contribute to reliability in continuous-duty applications.

Types and Applications

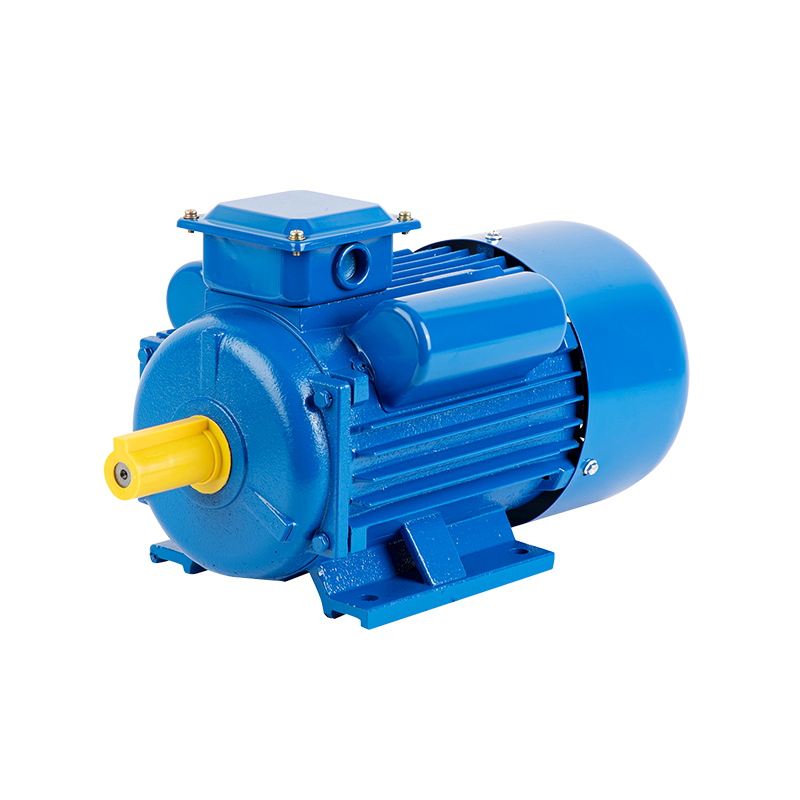

There are several types of AC Electric Motors, including single-phase and three-phase motors. Single-phase motors are commonly used for household appliances and small machinery, while three-phase motors are suited for industrial equipment requiring higher power and efficiency.

These motors are essential in applications like water pumps, HVAC systems, compressors, and conveyor belts. Their versatility and adaptability allow them to be used across many sectors, including manufacturing, agriculture, and infrastructure projects.

Efficiency and Performance

Efficiency is a key factor when selecting an AC Electric Motor. A well-designed motor can reduce energy consumption, lower operating costs, and improve overall system performance. Factors such as torque, speed, and load handling capacity are considered during motor selection.

Many factories and facilities evaluate motors based on service factor, insulation class, and thermal rating to ensure long-term performance. Consistent maintenance, including lubrication and cleaning, further extends motor life.

Maintenance and Reliability

Maintenance of an AC Electric Motor is straightforward but important. Regular checks on bearings, electrical connections, and cooling systems help prevent unexpected downtime. Manufacturers often provide detailed guidelines for maintenance schedules and troubleshooting tips.

A motor that is well-maintained not only operates efficiently but also reduces the likelihood of mechanical or electrical failures. For industrial settings, this translates to continuous production and fewer interruptions.

Choosing the Right AC Electric Motor

When selecting an AC Electric Motor, buyers should consider voltage requirements, power ratings, mounting options, and environmental conditions. A motor that matches operational needs while adhering to safety and efficiency standards ensures reliable service.

Additionally, working with a manufacturer that provides technical support, spare parts, and performance documentation enhances confidence in long-term use. Custom solutions may also be available for specific industrial or commercial applications.

The AC Electric Motor is a versatile and essential device for converting electrical energy into mechanical motion. Its design, efficiency, and range of applications make it valuable in industrial, commercial, and residential contexts. By understanding types, maintenance, and operational requirements, buyers can select motors that provide reliable performance, energy efficiency, and long service life.

With careful selection and regular upkeep, an AC electric motor can deliver consistent operation across various machinery and equipment, supporting productivity and reducing operational costs over time.