Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

What is an industrial pump motor?

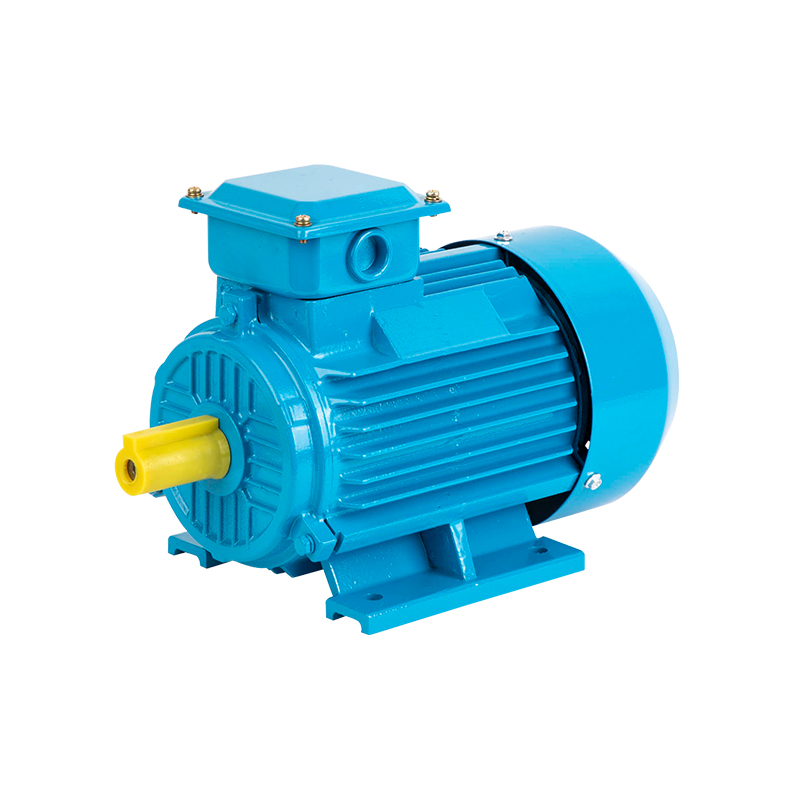

An industrial pump motor is an electric motor specifically designed to drive pumps in industrial settings. Its primary purpose is to convert electrical energy into mechanical energy to move fluids, including water, chemicals, oil, or slurry, through piping systems. Unlike general-purpose motors, an industrial pump motor is built to handle demanding conditions such as continuous operation, variable loads, and harsh environmental factors. It is widely used in industries such as manufacturing, chemical processing, water treatment, and oil and gas, where reliable fluid movement is essential.

How does an industrial pump motor work?

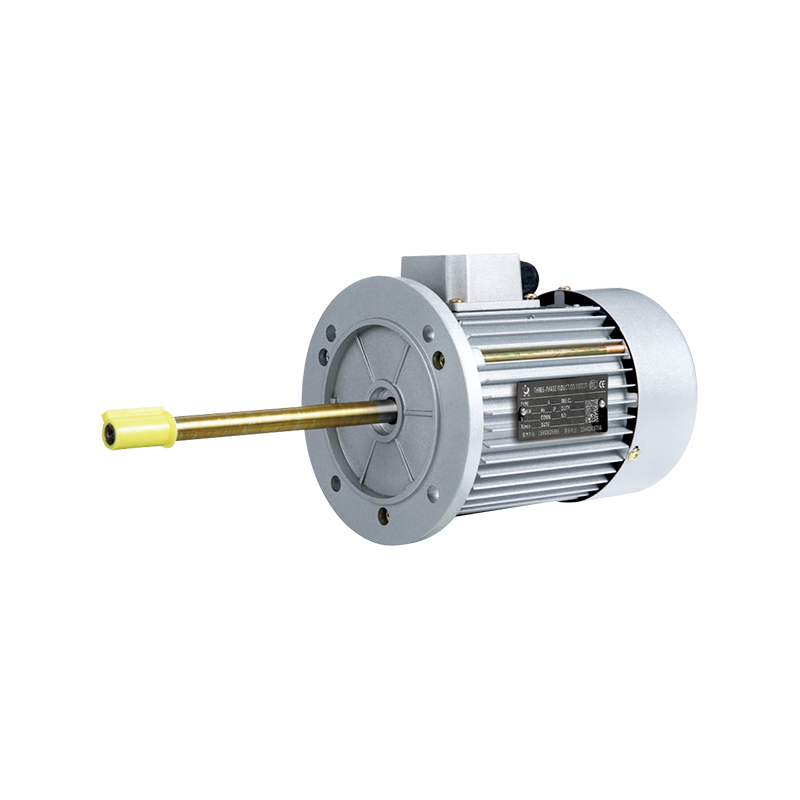

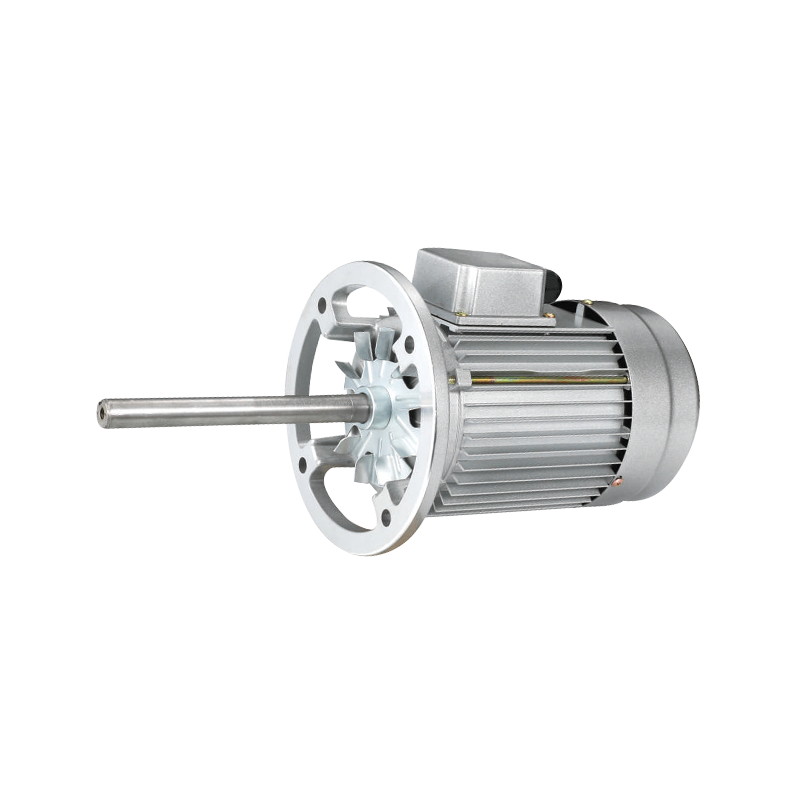

An industrial pump motor operates by generating rotational motion that drives the pump’s shaft. When electricity flows through the motor’s windings, it creates a magnetic field in the stator, which causes the rotor to rotate. This rotational energy is transferred to the pump impeller or piston, causing the fluid to flow through the system. The performance of the motor directly affects the pump’s efficiency, flow rate, and pressure. Many modern industrial pump motors are compatible with variable frequency drives (VFDs), which allow the motor speed to be adjusted according to the system’s requirements. This not only improves energy efficiency but also reduces wear and tear on the motor and pump components.

What types of industrial pump motors are available?

There are several types of industrial pump motors, each suited for specific applications:

- AC Induction Motors: These are the commonly used motors for industrial pumps due to their reliability, durability, and simple design. They are suitable for continuous operations in industrial environments.

- DC Motors: DC motors provide precise speed control, making them ideal for processes that require variable flow rates or pressures. While they offer control, they generally require more maintenance than AC motors.

- Synchronous Motors: These motors maintain a constant speed regardless of load variations, offering high efficiency for applications that demand precise flow control.

- Explosion-Proof Motors: Designed for hazardous environments, explosion-proof industrial pump motors prevent sparks from igniting flammable gases, dust, or chemicals.

- Variable Frequency Drive (VFD) Motors: VFD-compatible motors allow for adjustable speed and torque, improving energy efficiency and operational flexibility.

Why are these differences important?

Choosing the correct type of industrial pump motor ensures that the pump operates efficiently and reliably. For instance, in applications requiring constant high flow, an AC induction motor may be sufficient, while processes needing precise control might benefit from a DC or VFD motor. Similarly, hazardous environments necessitate explosion-proof motors to ensure safety and compliance with regulations.

What should be considered during installation and operation?

When installing an industrial pump motor, proper alignment with the pump is critical to avoid excessive vibration and premature wear. Ensuring that the motor is correctly rated for the load and environmental conditions also extends its service life. Regular maintenance, including lubrication of bearings, inspection of electrical connections, and monitoring for unusual vibrations or noise, is essential to maintain performance.

An industrial pump motor is designed to efficiently move fluids in demanding environments, and choosing the appropriate type ensures performance, energy efficiency, and longevity. Proper installation and maintenance further contribute to reliable and safe operation across various industrial applications.