Building 1, Block 4, Wufeng Industrial Park, Daxi Town, Taizhou City, Zhejiang Province, China

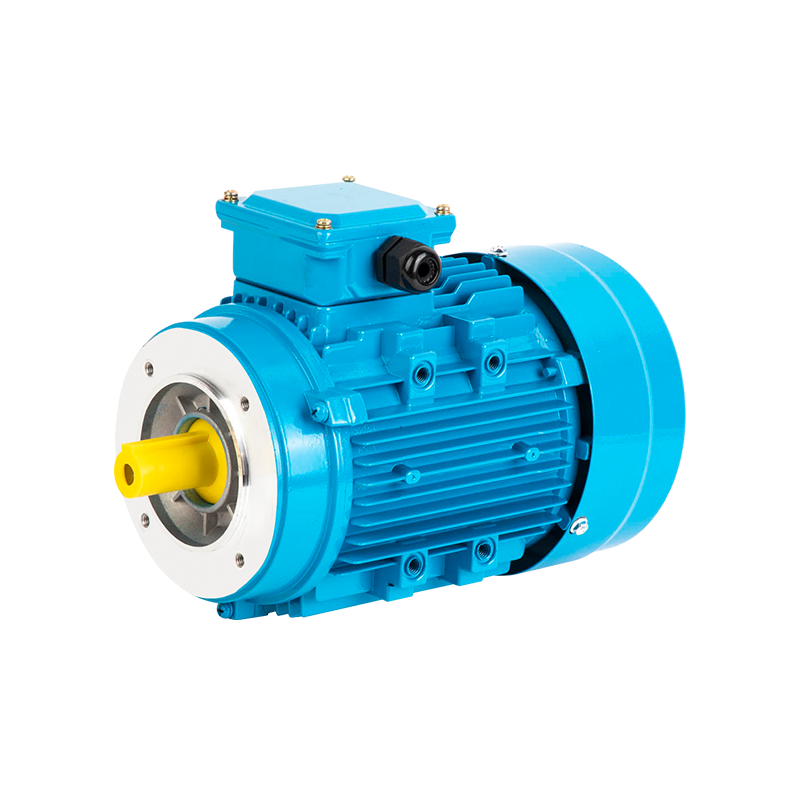

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When standard motors do not meet unique design or performance needs, an OEM Custom Electric Motor can provide a tailored solution. Understanding how these motors are designed and manufactured helps buyers make informed decisions for their projects.

An OEM Custom Electric Motor is specifically designed according to a client's technical requirements. Manufacturers adjust parameters such as voltage, speed, torque, size, and mounting configurations to match specific operational conditions. This approach allows businesses to integrate motors that are fully compatible with their machinery or products without compromising performance.

Customization also extends to insulation class, shaft design, and cooling methods, depending on the motor's application. By offering tailored solutions, manufacturers help clients address unique challenges and requirements.

Manufacturing Process

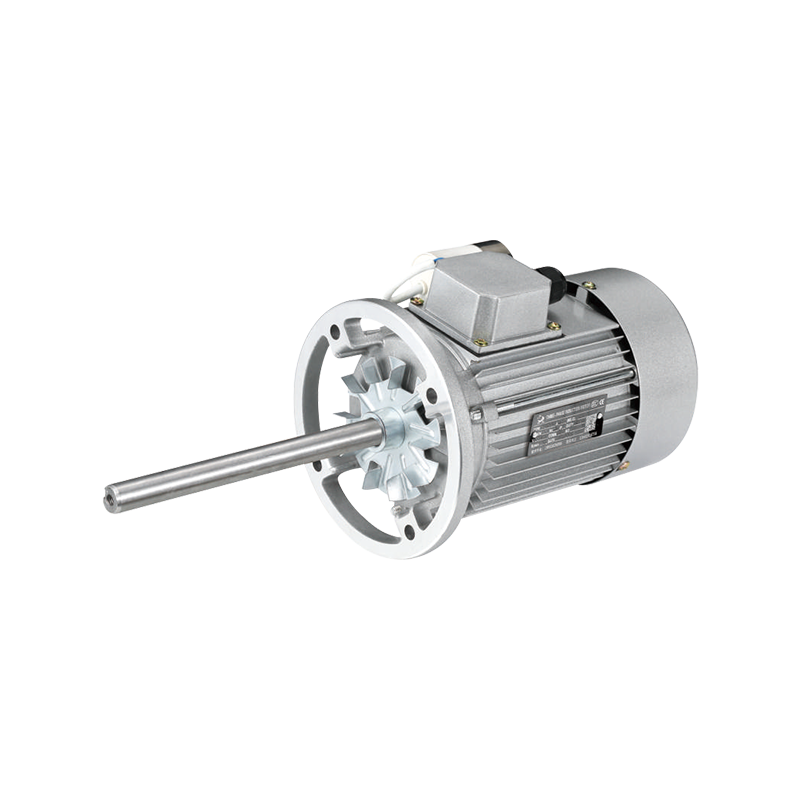

The production of an OEM Custom Electric Motor involves several stages to ensure reliability and consistency. It begins with material selection, where high-quality copper windings, magnetic cores, and durable housing materials are chosen based on performance needs.

Precision machining and winding processes are critical in achieving consistent torque and speed characteristics. After assembly, motors undergo rigorous testing for efficiency, noise levels, vibration, and thermal performance. These steps ensure that the final product performs reliably under intended operating conditions.

Applications and Use Cases

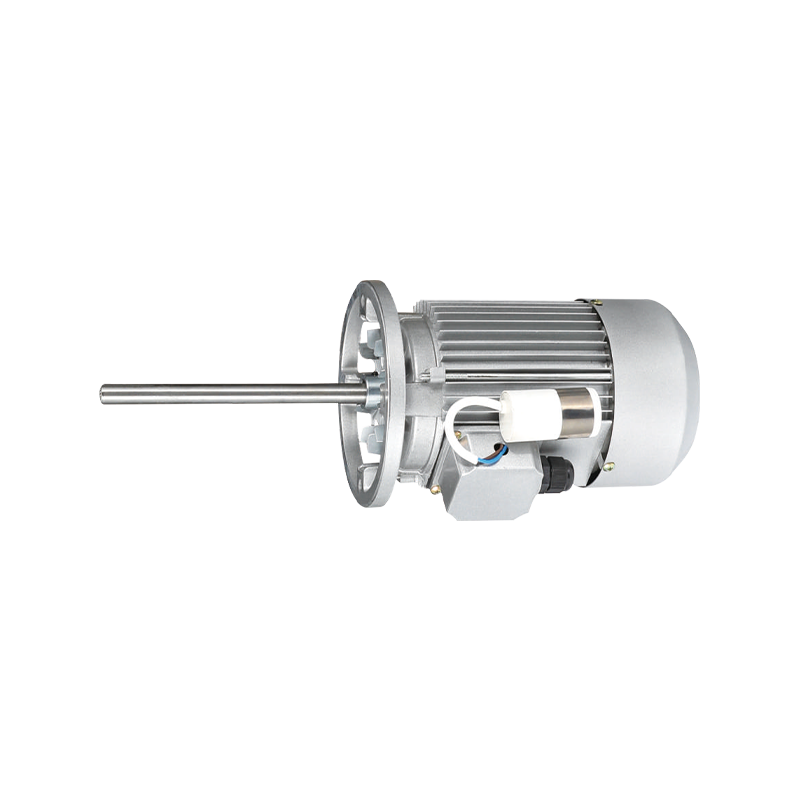

OEM Custom Electric Motors are widely used across multiple industries. In industrial machinery, they drive conveyors, pumps, and compressors with specific torque and speed requirements. In automotive and robotics applications, customized motors can match unique power and size constraints.

Even in household appliances such as washing machines, fans, or kitchen devices, OEM motors are designed to fit the device's form factor and meet regulatory standards for safety and efficiency. Customization ensures seamless integration into the client's product while maintaining consistent performance.

Quality Control and Compliance

Manufacturers producing OEM Custom Electric Motors typically follow strict quality control procedures. Testing includes electrical safety checks, performance validation, and durability assessments. Compliance with international standards and certifications, such as CE or UL, may also be part of the manufacturing process, particularly for export markets.

These measures help clients trust that their custom motors meet both functional and safety requirements, reducing the risk of failures in the field.

Benefits of Custom Solutions

Choosing an OEM Custom Electric Motor offers several advantages. It ensures that the motor is fully compatible with the client's product design, reduces installation challenges, and can improve operational efficiency. Custom motors also allow businesses to differentiate their products, as the motor can be tailored to specific performance, size, or noise requirements.

Moreover, working closely with the manufacturer enables technical support throughout the design, prototyping, and production stages, helping clients achieve reliable results.

An OEM Custom Electric Motor provides a practical solution for projects that require tailored performance and integration. By focusing on customization, precision manufacturing, and quality control, manufacturers help clients meet their unique operational needs. Understanding the benefits, applications, and production processes of custom electric motors allows buyers to select solutions that enhance efficiency, compatibility, and reliability across a wide range of industries.