Single phase AC motors are commonly used in homes, small industries, and light commercial applications. These motors operate on a single-phase alterna...

READ MORE

- Y2 Series Three-Phase Asynchronous Motor

- YE3 Series High Efficiency Three-Phase Asynchronous Motor

- YCL Series Double Value Capacitor Asynchronous Motor

- YL Series Double Value Capacitor Asynchronous Motor

- YY Series Capacitor Run Asynchronous Motor

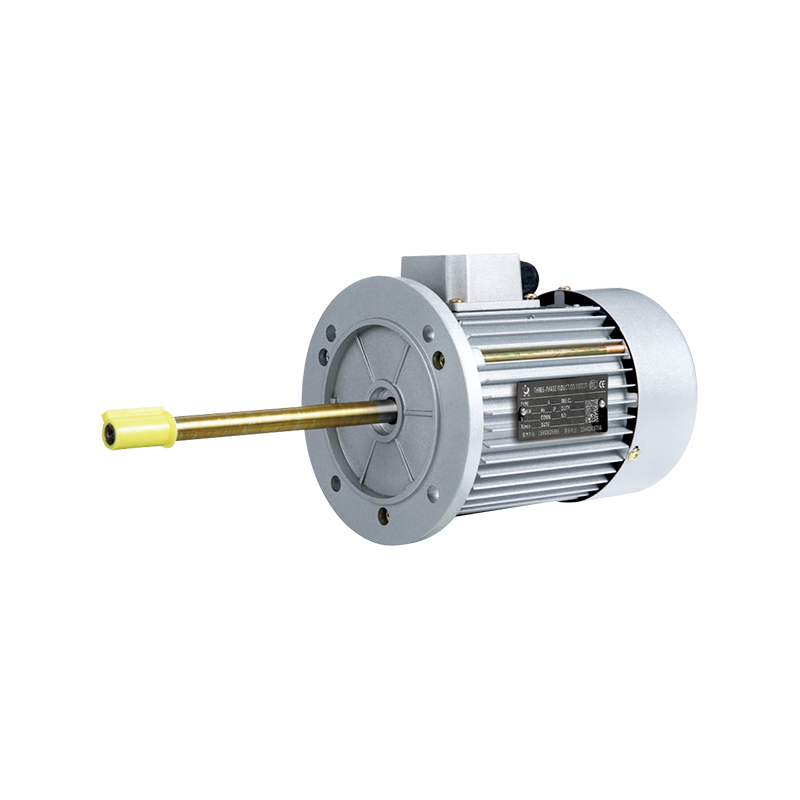

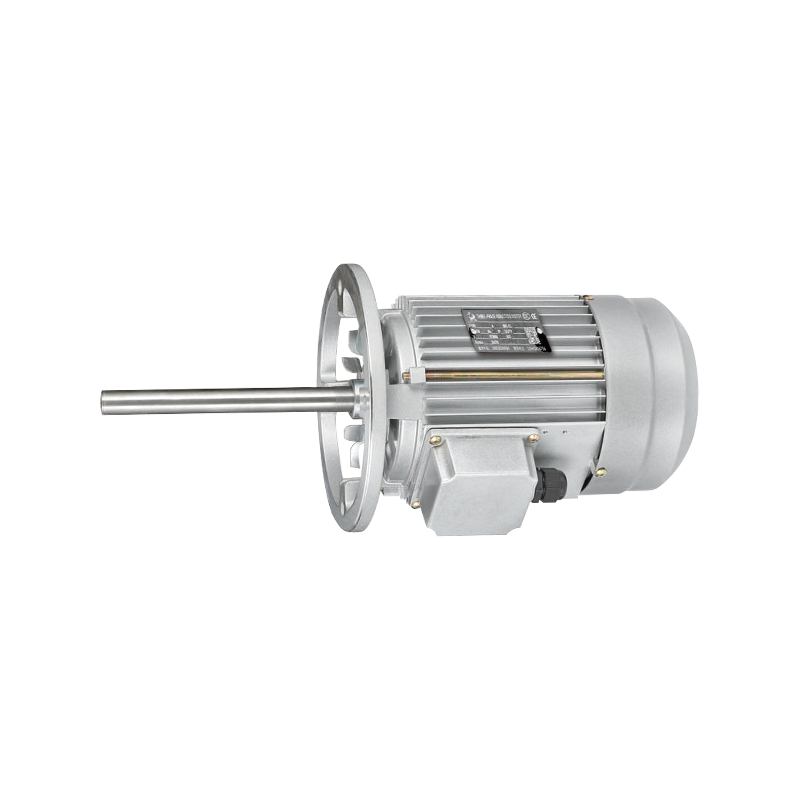

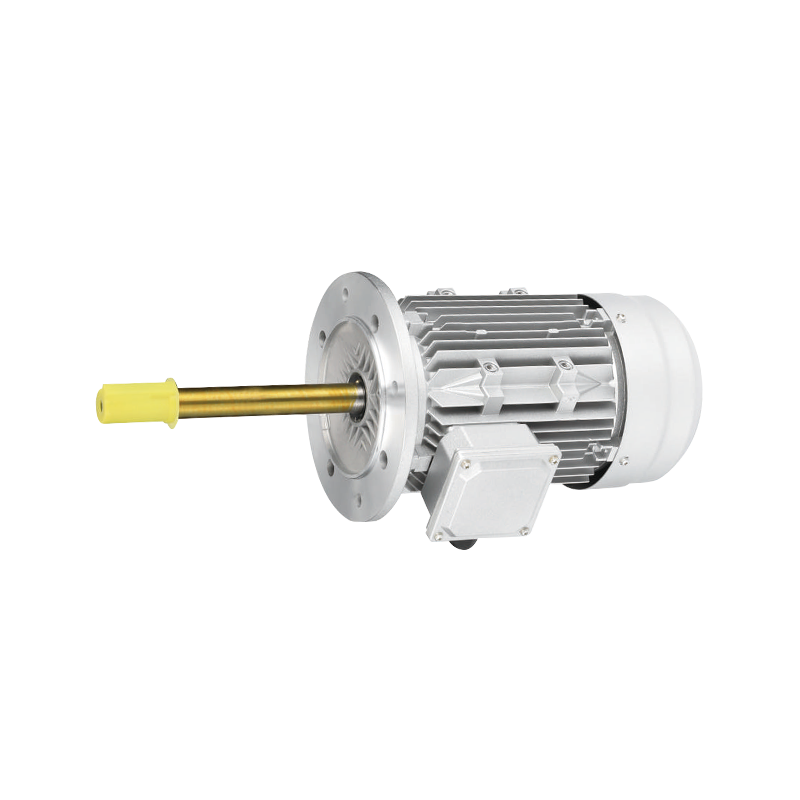

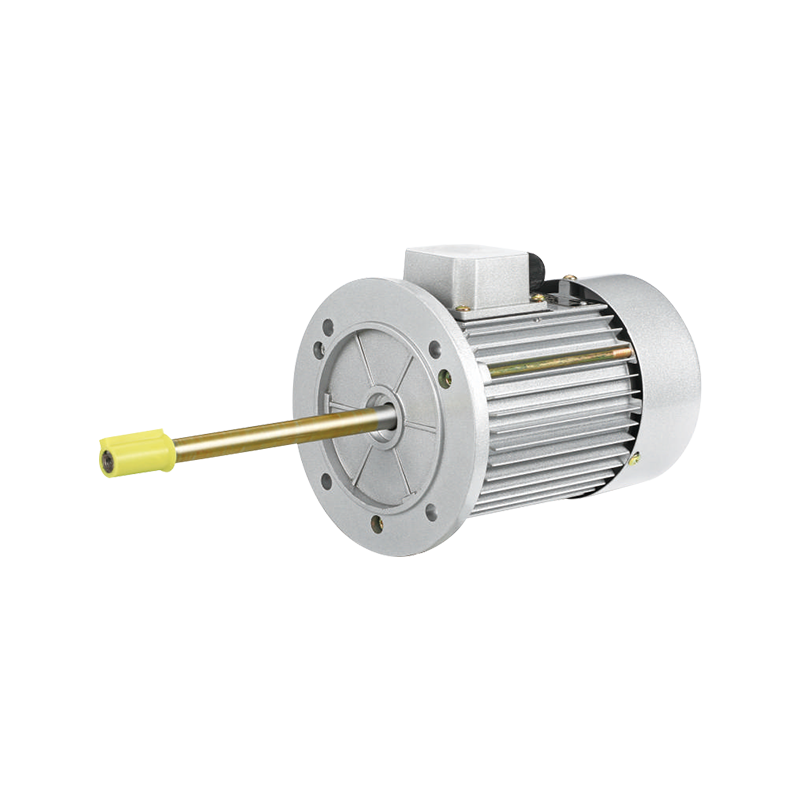

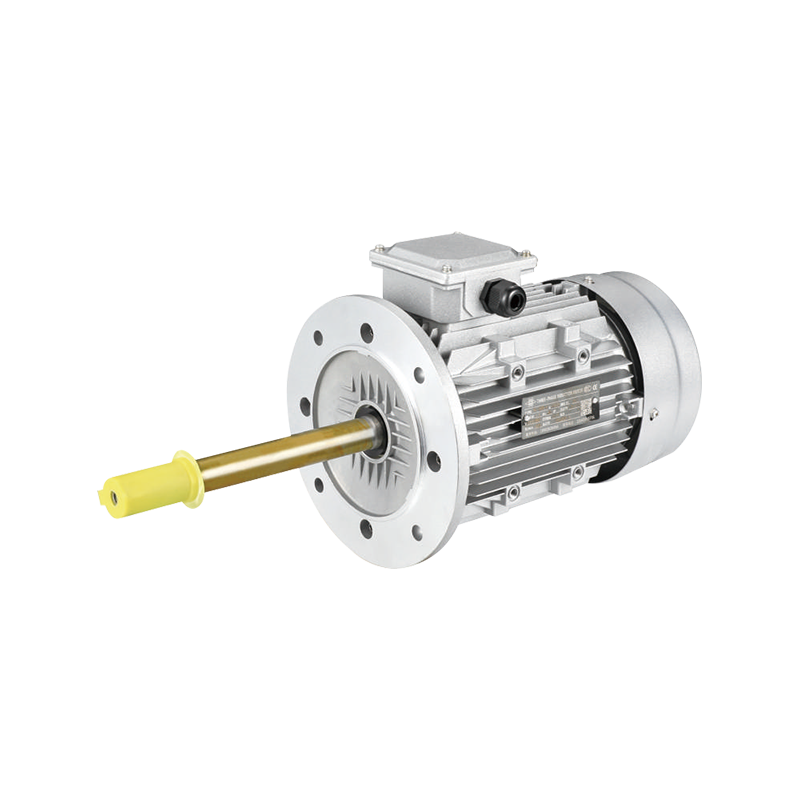

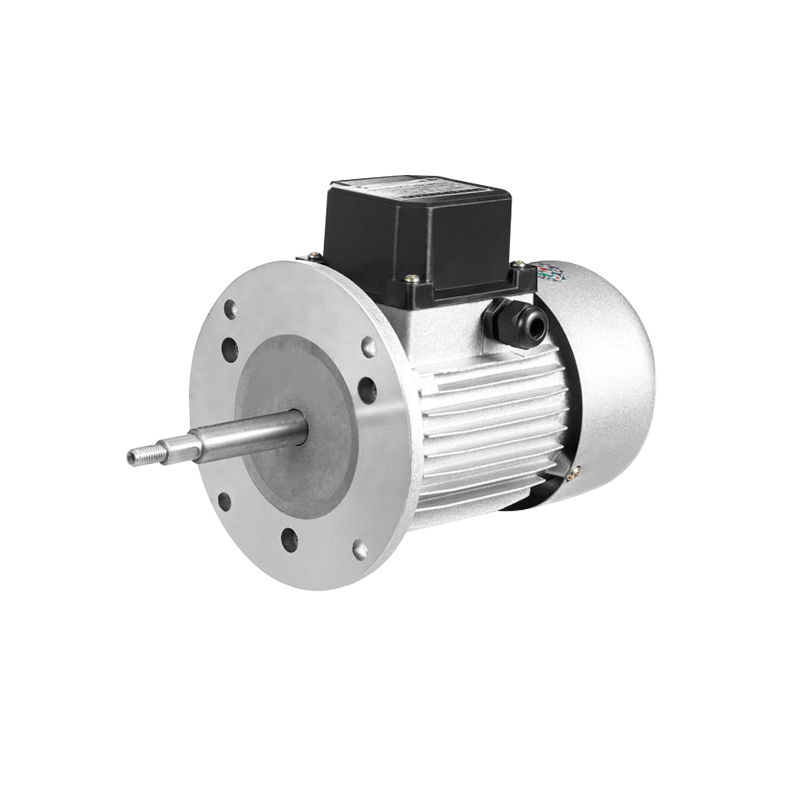

- Customized Long Shaft Motor

- YE4 Series High Efficiency Three-Phase Asynchronous Motor

- Electric Vacuum Pump

- High Pressure Washer

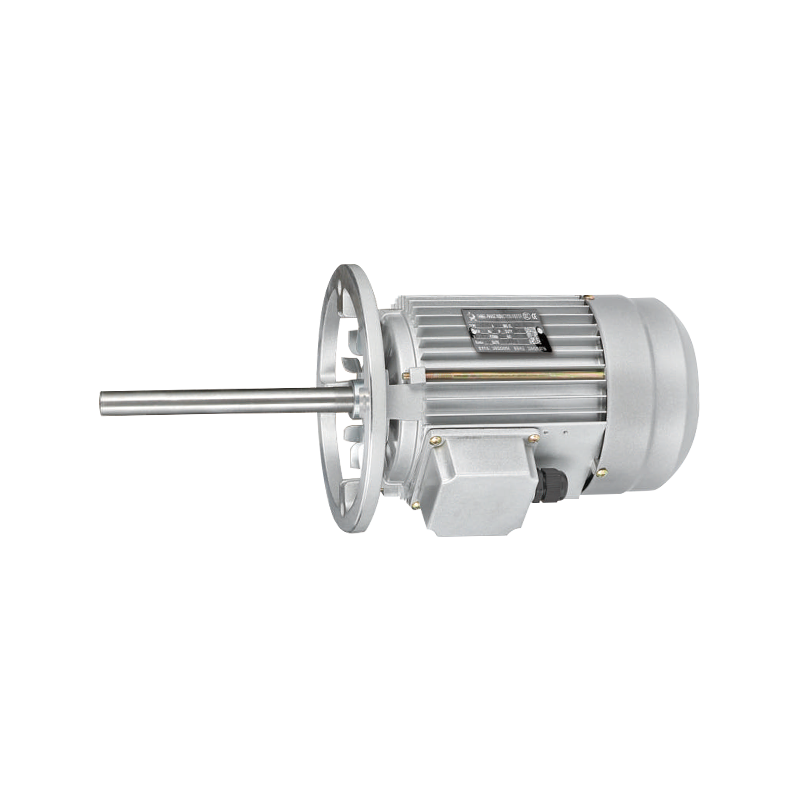

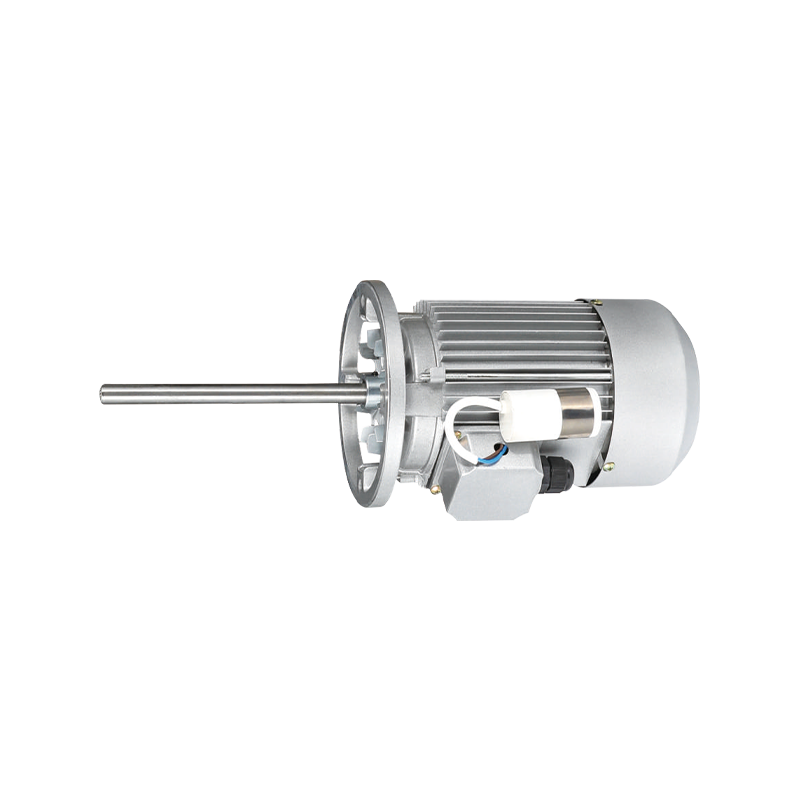

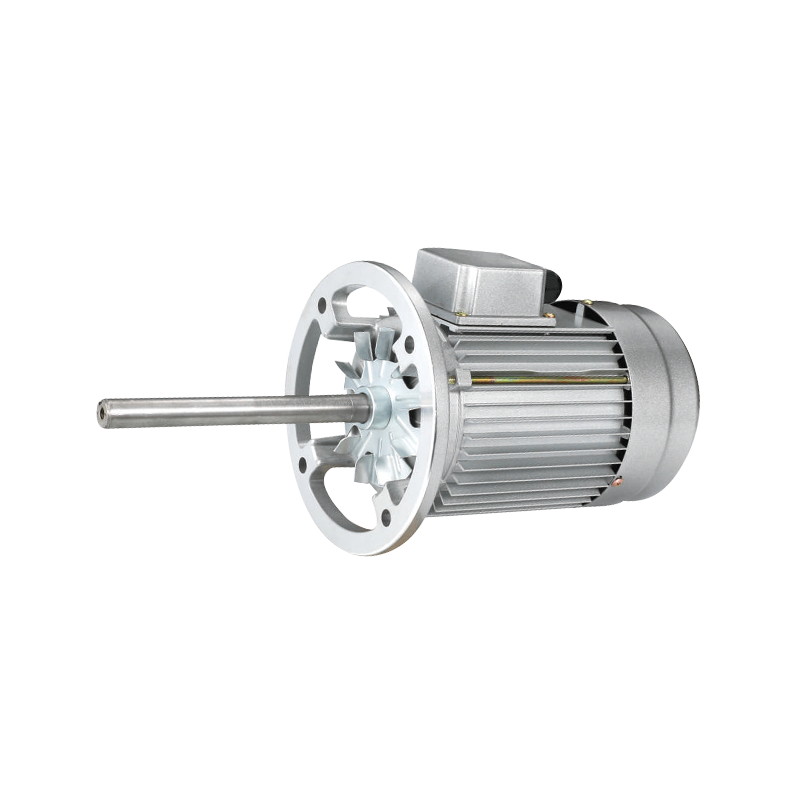

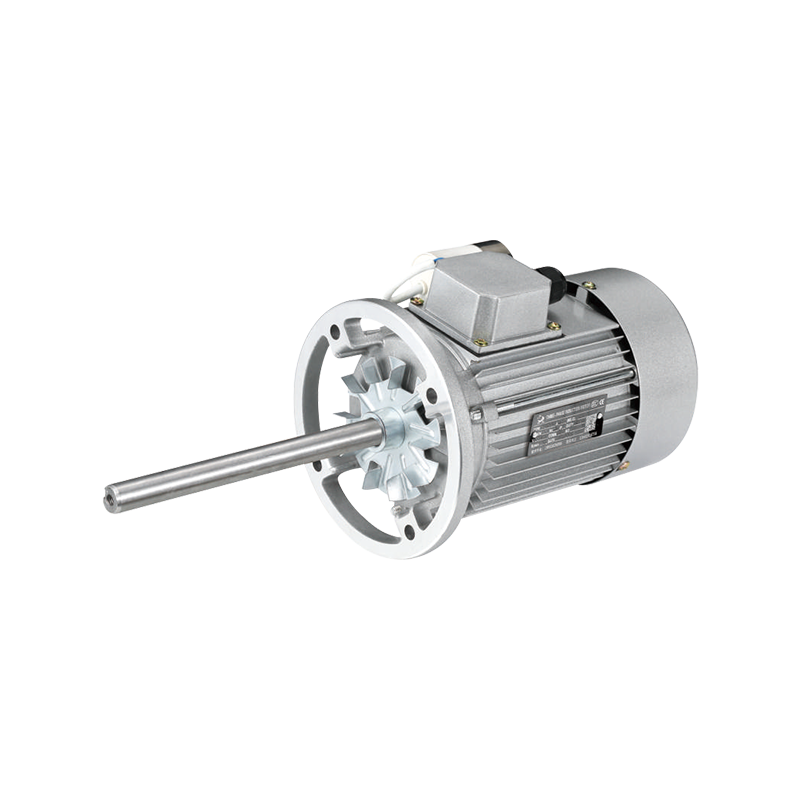

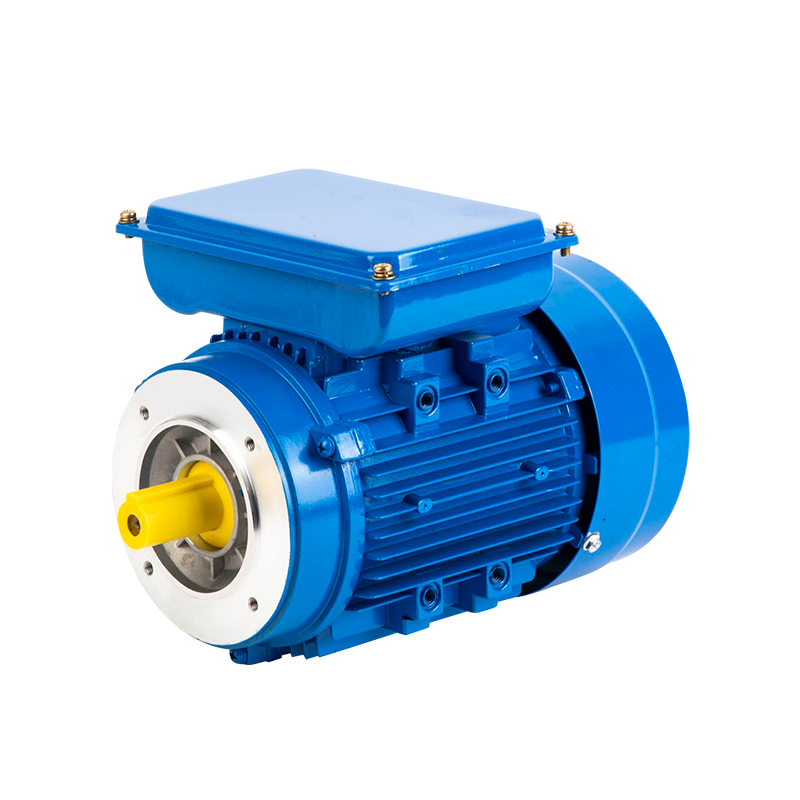

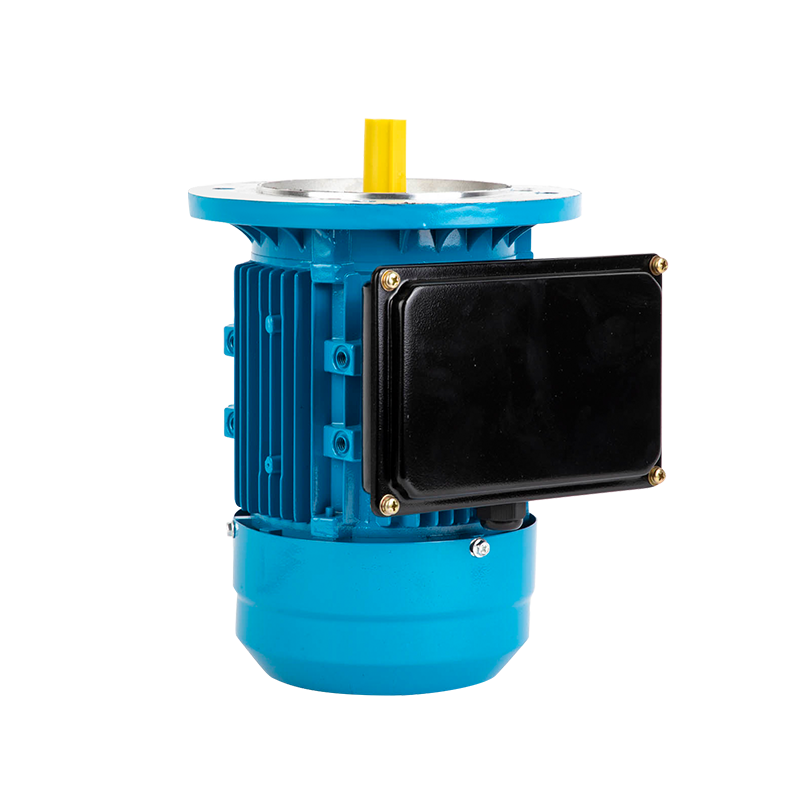

China Motor With Long Shaft

The Customized Long Shaft Motor is a specially engineered solution tailored for unique industrial applications that require extended shaft lengths and non-standard configurations. Designed to overcome the spatial limitations of traditional motors, these units offer customizable options—including shaft length, flange size, voltage, and mounting style—to meet specific operational requirements.

Constructed with high-strength alloy steel shafts and subjected to precision dynamic balancing, these motors ensure smooth, stable, and vibration-free operation even during long-distance torque transmission. This makes them particularly well-suited for textile machinery, food processing lines, and other equipment where standard motor dimensions are inadequate.

Ideal for applications involving remote or offset mechanical drives, the Customized Long Shaft Motor delivers reliable performance in compact installations without sacrificing power or durability. The extended shaft design helps eliminate the need for intermediate couplings or additional transmission components, thereby reducing system complexity, improving alignment accuracy, and minimizing maintenance requirements.

Whether addressing design constraints, specialized equipment configurations, or specific functional needs, the Customized Long Shaft Motor offers a powerful combination of flexibility, precision, and high-performance operation.

Get Your Free Quote Now!

-

-

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When standard motors do n...

READ MORE -

Three-phase AC motors are widely used in industrial machinery, manufacturing lines, pumps, and HVAC systems. Selecting a reliable Three Phase AC Moto...

READ MORE -

AC electric motors are widely used in industries ranging from manufacturing to HVAC systems and household appliances. To ensure reliability and effic...

READ MORE

What Makes a Customized Long Shaft Motor Unique?

A Customized Long Shaft Motor is designed to meet specific industrial needs where standard motors cannot fit or perform adequately. By extending the motor shaft length, these motors can connect directly to specialized equipment such as pumps, conveyors, mixers, or extruders without additional couplings or adapters. From a manufacturer's perspective, offering customization ensures that clients receive a motor tailored to their precise operational requirements, improving efficiency, reducing installation complexity, and minimizing maintenance issues.

How Does a Motor With Long Shaft Improve Industrial Efficiency?

Long shaft motors allow for direct transmission of mechanical power to equipment, reducing energy losses that typically occur with intermediate gears or pulleys. This direct drive capability ensures smoother operation and consistent torque delivery. Industries such as water treatment, chemical processing, and large-scale manufacturing benefit from these motors because they provide reliable performance under continuous operation. With a properly designed long shaft, vibration and misalignment issues are minimized, prolonging both the motor's lifespan and the connected machinery.

What Materials and Designs Ensure Durability?

From a manufacturing perspective, durability is a top priority. Long shaft motors are typically constructed with high-grade steel for the shaft and robust cast iron or aluminum for the housing. Precision bearings and advanced insulation systems are used to ensure stability during extended operations. Thermal protection features prevent overheating, while anti-corrosion coatings and robust sealing options make the motors suitable for harsh environments, including high humidity, dust, or exposure to chemicals.

Which Applications Benefit Most From Long Shaft Engines?

Industries with specialized mechanical layouts often require long shaft engines. For instance:

| Industry | Application | Advantage of Long Shaft Motor |

| Water Treatment | Large pumps | Direct connection, reduced energy loss |

| Manufacturing | Conveyor systems | Smooth torque transmission, less vibration |

| Food Processing | Mixers and blenders | Compact integration with machines, hygienic sealing options |

| Chemical Plants | Agitators | High reliability under corrosive or high-temperature environments |

By understanding the unique requirements of each application, manufacturers can recommend motors with the appropriate shaft length, torque rating, and mounting configuration.

How Can Customized Options Enhance Performance?

Customization options allow clients to specify parameters such as shaft diameter, shaft length, flange type, insulation class, and cooling method. For example, a motor can be adapted with a longer or reinforced shaft to drive multiple devices simultaneously or operate under heavy load conditions. Additionally, manufacturers can provide motors with specialized coatings for marine environments, high-temperature insulation for ovens or kilns, or vibration-dampening features for sensitive equipment. These tailored solutions not only optimize motor performance but also increase operational safety and reduce downtime.

Why Choose a Manufacturer-Driven Approach?

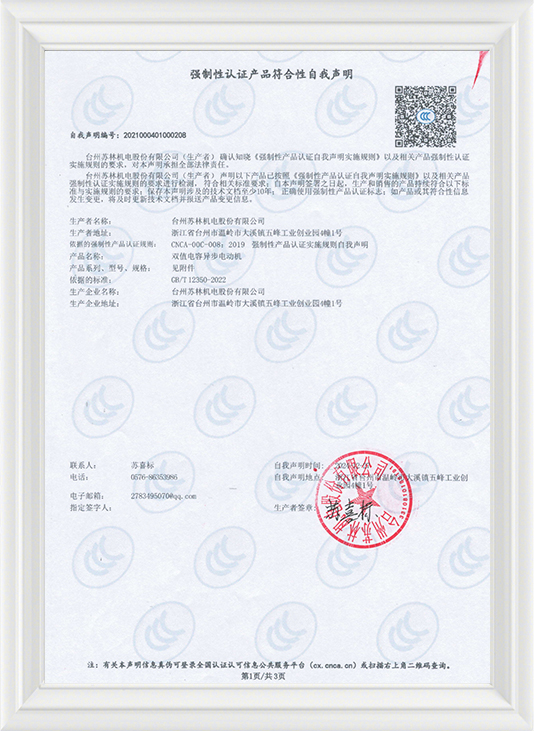

Working directly with a manufacturer ensures access to expert engineering support, rigorous quality control, and the ability to iterate designs based on real-world requirements. Manufacturers can perform precise testing, such as vibration analysis, thermal endurance tests, and torque validation, ensuring the long shaft motor meets both performance and safety standards. Furthermore, factory-level customization reduces delivery times and allows for flexible production to meet urgent project needs.

How Does a Long Shaft Motor Simplify Maintenance?

Long shaft motors reduce the need for additional mechanical couplings, which are common points of wear and alignment issues. This direct-drive approach simplifies maintenance schedules, lowers spare part requirements, and improves overall system reliability. For industrial operators, this means fewer shutdowns, lower operational costs, and improved productivity over the motor's lifecycle.

Customized Long Shaft Motors provide a balance of flexibility, durability, and efficiency for specialized industrial applications. By leveraging manufacturing expertise, businesses can ensure motors are tailored to their exact requirements, improving performance and reducing long-term costs. From water treatment plants to large-scale manufacturing operations, long shaft motors represent a practical and reliable solution for direct mechanical power transmission.