Single phase AC motors are commonly used in homes, small industries, and light commercial applications. These motors operate on a single-phase alterna...

READ MORE

- Y2 Series Three-Phase Asynchronous Motor

- YE3 Series High Efficiency Three-Phase Asynchronous Motor

- YCL Series Double Value Capacitor Asynchronous Motor

- YL Series Double Value Capacitor Asynchronous Motor

- YY Series Capacitor Run Asynchronous Motor

- Customized Long Shaft Motor

- YE4 Series High Efficiency Three-Phase Asynchronous Motor

- Electric Vacuum Pump

- High Pressure Washer

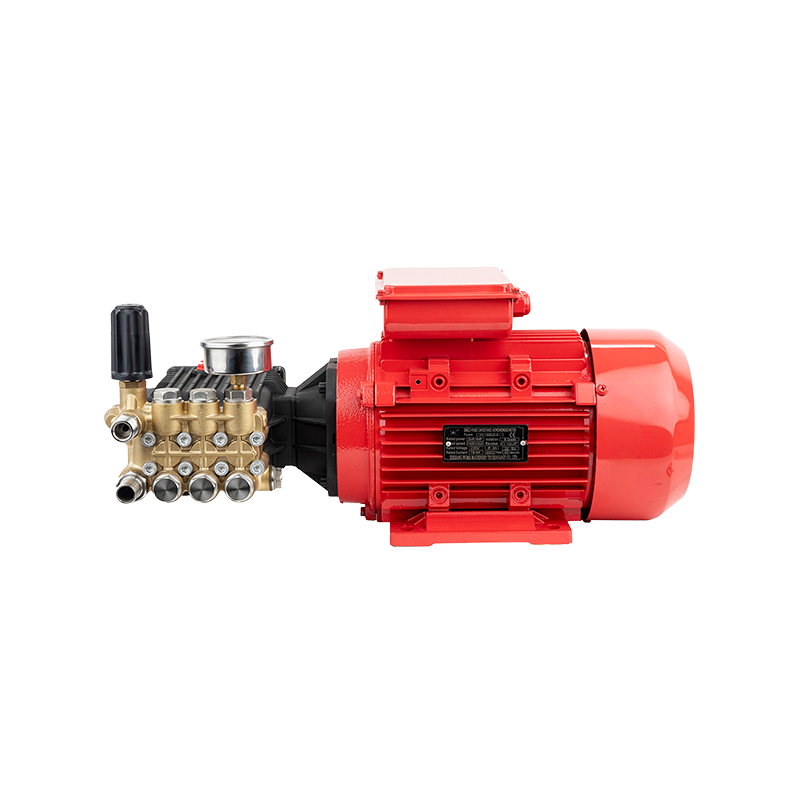

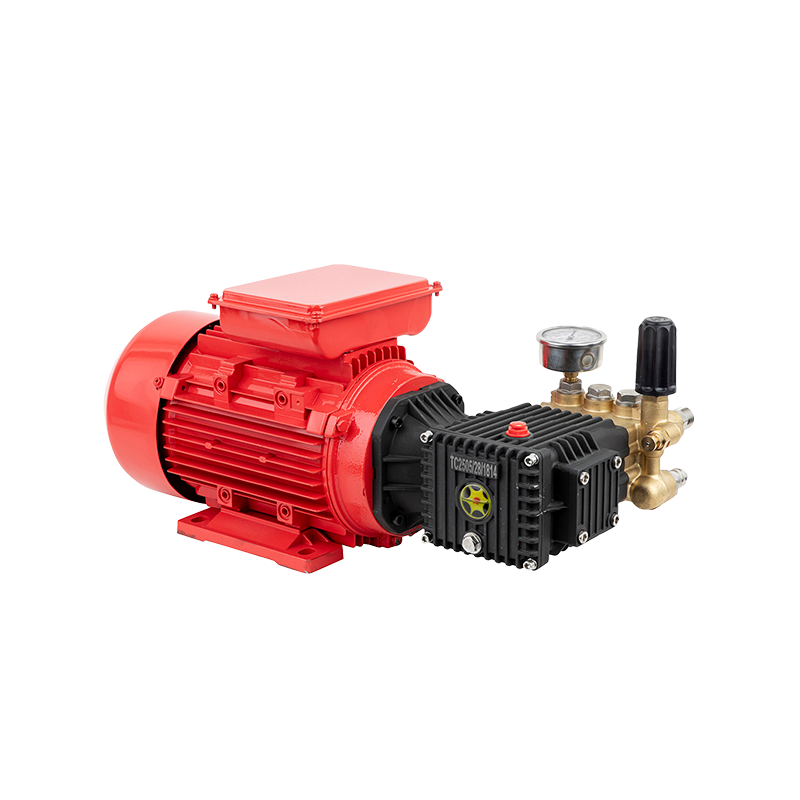

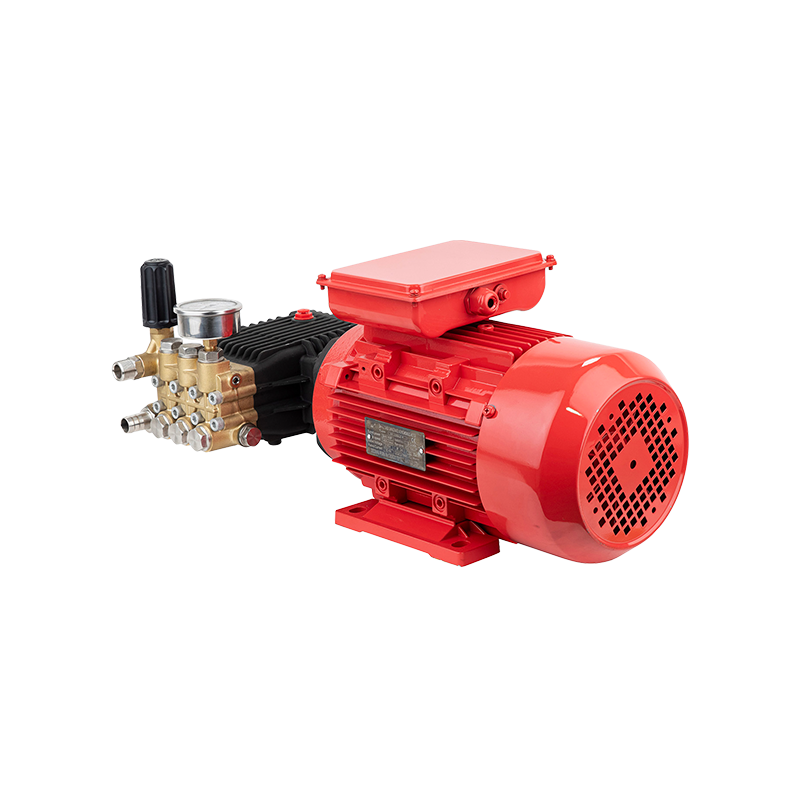

High Pressure Washer Motor Supplier

High pressure washers can be classified based on their functionality, design, and adaptability to various cleaning needs. This versatile high pressure washer is a powerful cleaning tool designed for both residential and industrial applications. It effectively removes dirt, grime, and stubborn stains from surfaces such as home siding, driveways, vehicles, patio furniture, and industrial machinery.

Engineered with a self-developed all-copper pump head and a high-performance motor, this washer ensures reliable performance under tough conditions. The durable stainless steel shell enhances longevity, while the IPX5 waterproof rating ensures safe outdoor operation. A key feature is its dual water source capability—users can connect the washer directly to a faucet or draw water via suction from a bucket, enabling flexible use in various environments, including locations without a pressurized water supply.

Equipped with multiple nozzles at different spray angles, this washer offers customizable pressure settings to suit specific tasks. The visualized adjustable pressure control ensures precise output, while the advanced Total Stop System (TSS) automatically shuts off the pump when the trigger is not engaged, conserving energy and prolonging the unit’s lifespan.

Get Your Free Quote Now!

-

-

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When standard motors do n...

READ MORE -

Three-phase AC motors are widely used in industrial machinery, manufacturing lines, pumps, and HVAC systems. Selecting a reliable Three Phase AC Moto...

READ MORE -

AC electric motors are widely used in industries ranging from manufacturing to HVAC systems and household appliances. To ensure reliability and effic...

READ MORE

High Pressure Washer: An Essential Cleaning Solution

The High Pressure Washer has become an indispensable tool across industrial, commercial, and residential sectors. Its main advantage lies in its ability to generate strong water jets that effectively remove dirt, grease, mold, and debris from a wide range of surfaces. Unlike traditional cleaning methods that rely heavily on chemicals or manual scrubbing, a high pressure washer leverages mechanical force, saving both time and resources.

From a manufacturer's perspective, the high pressure washer is designed with durability, portability, and efficiency in mind. The build typically includes a robust steel frame, corrosion-resistant water pathways, and user-friendly controls. Industrial-grade versions are often customized with higher flow rates and stronger motors, ensuring they can handle continuous heavy-duty tasks such as factory floor cleaning, fleet washing, or construction site maintenance.

High Pressure Washer Motor: The Heart of the System

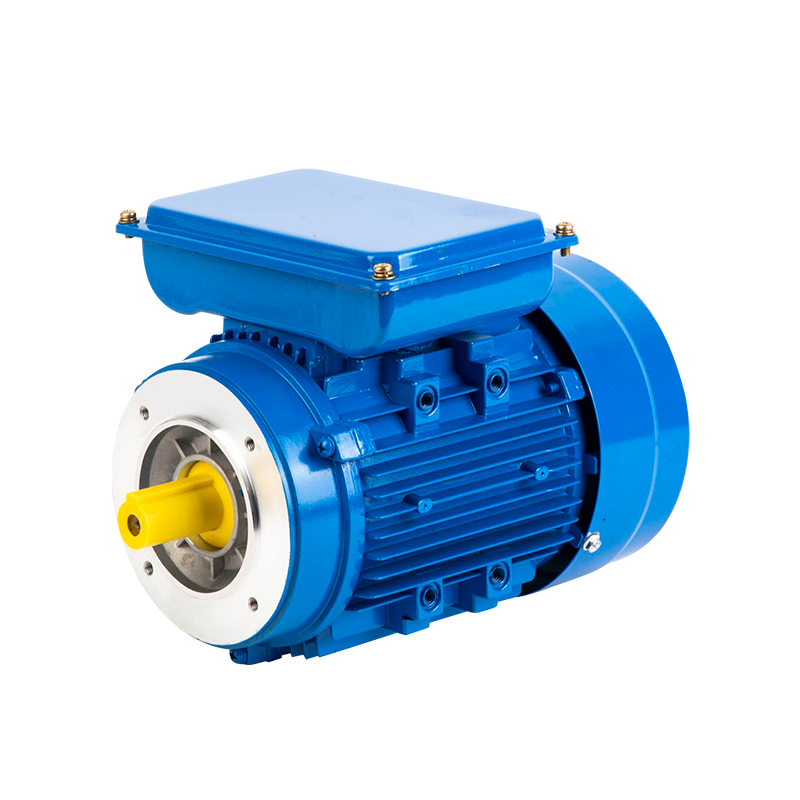

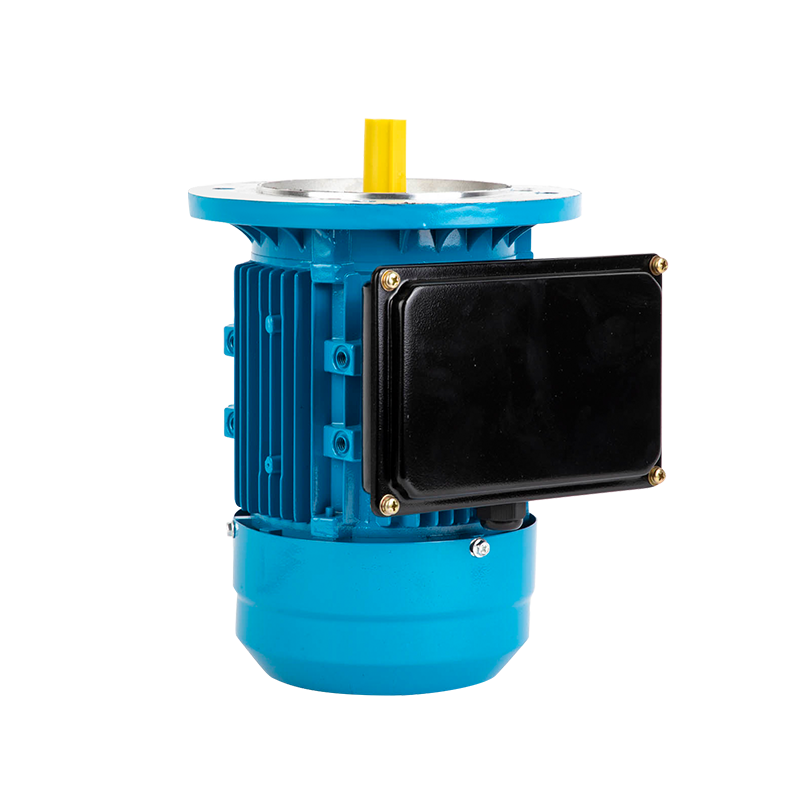

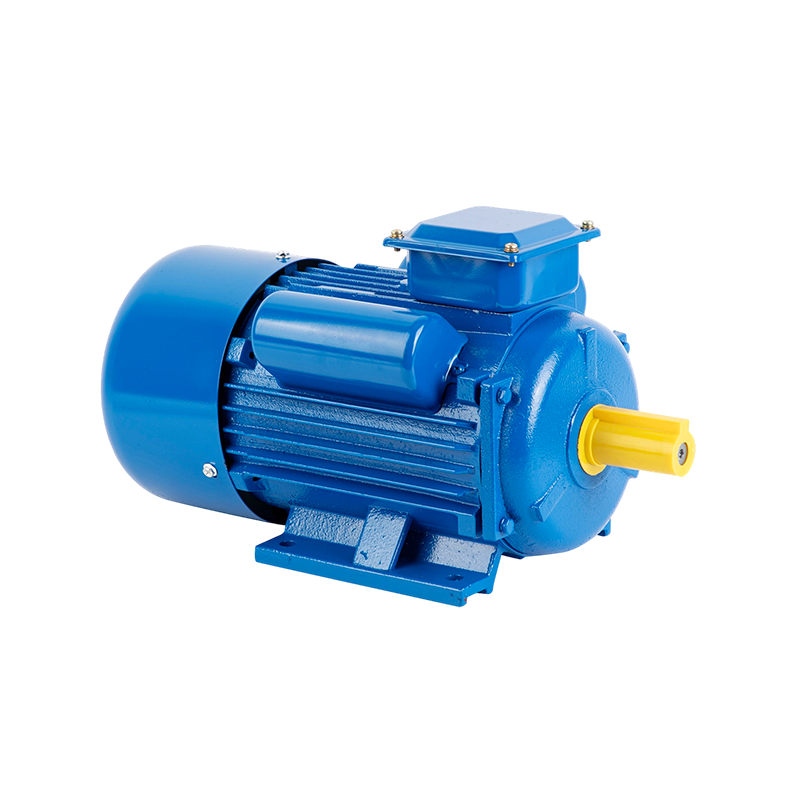

At the core of every high pressure washer is the High Pressure Washer Motor, which directly influences performance, reliability, and efficiency. Motors are available in both single-phase and three-phase configurations, allowing flexibility for residential or industrial use.

Electric motors are highly valued for their quiet operation, low emissions, and suitability for indoor environments.

Industrial motors are designed with overload protection, insulation systems, and energy-efficient winding to ensure long-term stability.

Manufacturers highlight that a high-quality high pressure washer motor not only improves water pressure consistency but also reduces energy waste, directly lowering operational costs. Advanced models often integrate thermal protection to safeguard against overheating, which is especially important for industries where the washer operates continuously.

High Pressure Washer Pump: Delivering Consistent Power

The High Pressure Washer Pump is the component that transforms motor energy into pressurized water flow. It is often regarded as critical mechanical part of the system. Manufacturers typically use brass, stainless steel, or ceramic pistons to ensure resistance against wear, corrosion, and high temperatures.

Key advantages of modern washer pumps include:

- High efficiency – delivering good water flow at reduced energy consumption.

- Durability – designed to withstand long operating hours without significant maintenance.

- Flexibility – available in direct-drive or belt-drive designs to suit different applications.

Industrial users rely on high pressure washer pumps for precision cleaning in sectors such as food processing, automotive manufacturing, and heavy equipment maintenance. The ability to maintain constant high pressure ensures a consistent cleaning standard, critical for industries that demand hygienic or contamination-free environments.

Applications Across Industries

- Automotive sector: Cleaning engines, undercarriages, and paint preparation.

- Construction industry: Removing cement, mud, and dust from heavy equipment.

- Agriculture: Washing tractors, storage tanks, and barns.

- Food and beverage: Maintaining hygiene in processing plants.

- Residential use: Driveway cleaning, façade washing, and garden equipment maintenance.

The combination of a high pressure washer motor and a high pressure washer pump ensures reliable performance in each of these scenarios, making the system adaptable for both small-scale and industrial-scale cleaning tasks.

Manufacturer's Advantages

From a manufacturing standpoint, offering high pressure washers with advanced motors and pumps allows differentiation in a competitive market. Manufacturers emphasize:

- Customization: Options for pressure levels, motor power, and pump material.

- Energy efficiency: Incorporation of high-efficiency electric motors that meet international energy standards.

- Durability: Use of industrial-grade components ensures reduced downtime.

- Support services: Providing OEM/ODM services, technical consultation, and spare part availability builds trust with wholesale buyers.

Future Trends and Buyer Considerations

As industries push toward sustainability, demand for high pressure washers with energy-efficient motors and pumps is growing. Buyers increasingly prioritize machines that reduce water usage while delivering high cleaning power. Smart monitoring features, such as digital pressure displays and automatic shut-off systems, are also becoming more popular.

Wholesale buyers are advised to consider:

- Motor efficiency to lower long-term energy costs.

- Pump material quality for resistance to wear and chemicals.

- Maintenance support to minimize downtime.

- Manufacturer reliability for long-term supply chain security.