Single phase AC motors are commonly used in homes, small industries, and light commercial applications. These motors operate on a single-phase alterna...

READ MORE

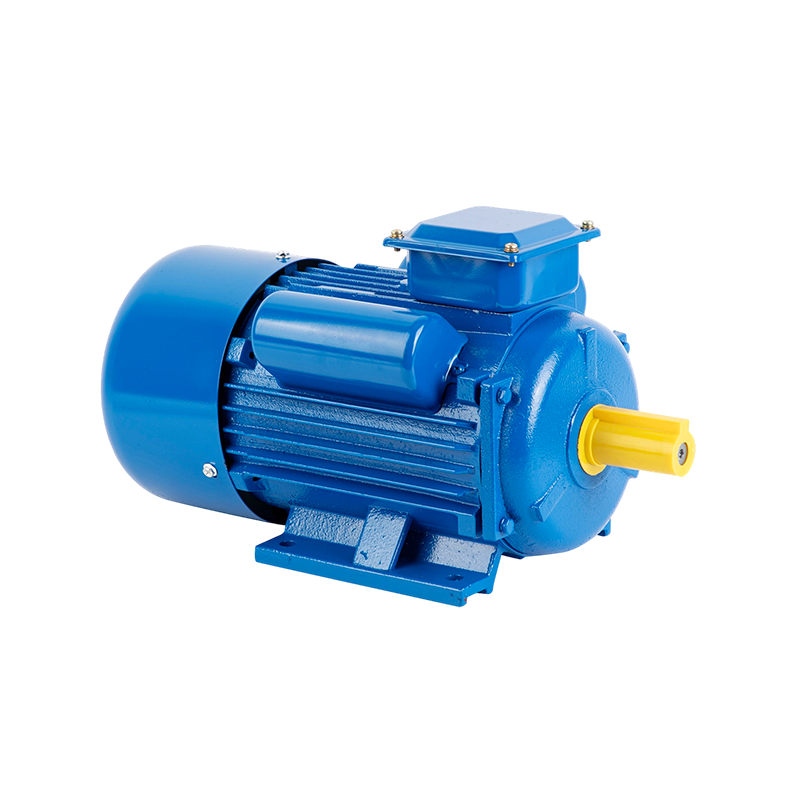

- Y2 Series Three-Phase Asynchronous Motor

- YE3 Series High Efficiency Three-Phase Asynchronous Motor

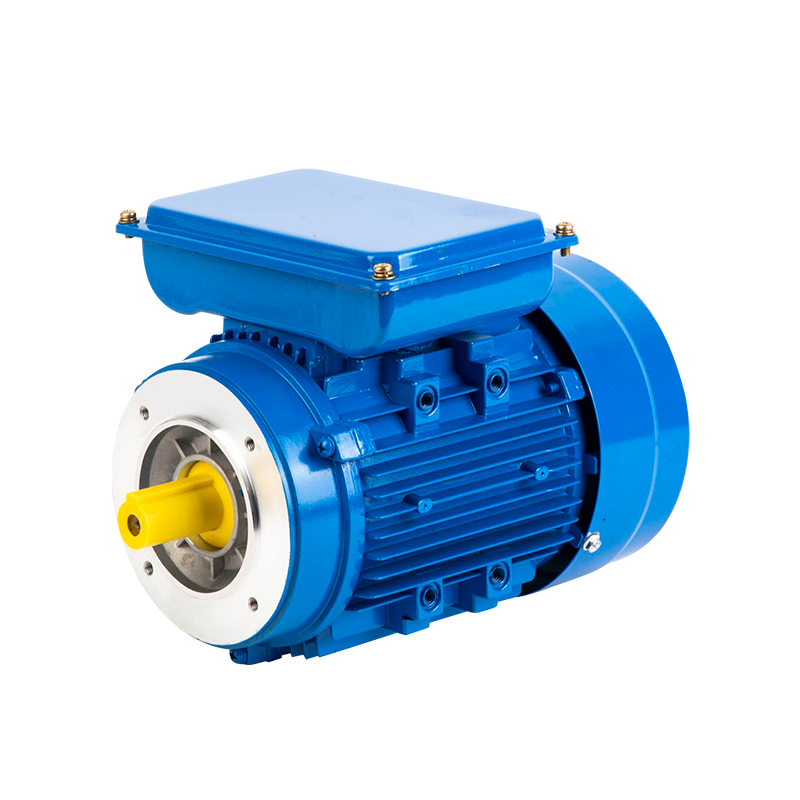

- YCL Series Double Value Capacitor Asynchronous Motor

- YL Series Double Value Capacitor Asynchronous Motor

- YY Series Capacitor Run Asynchronous Motor

- Customized Long Shaft Motor

- YE4 Series High Efficiency Three-Phase Asynchronous Motor

- Electric Vacuum Pump

- High Pressure Washer

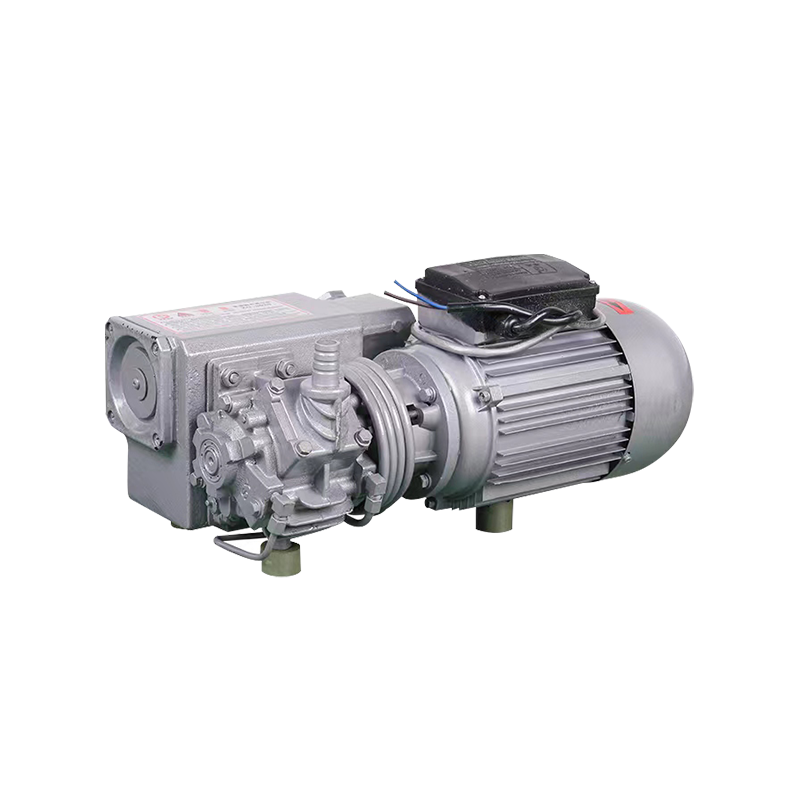

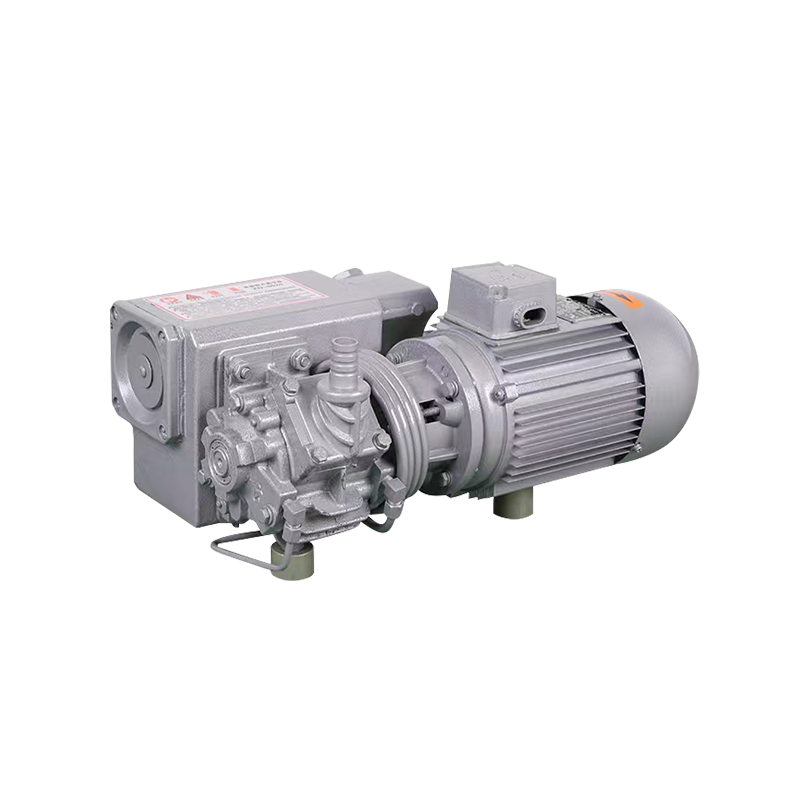

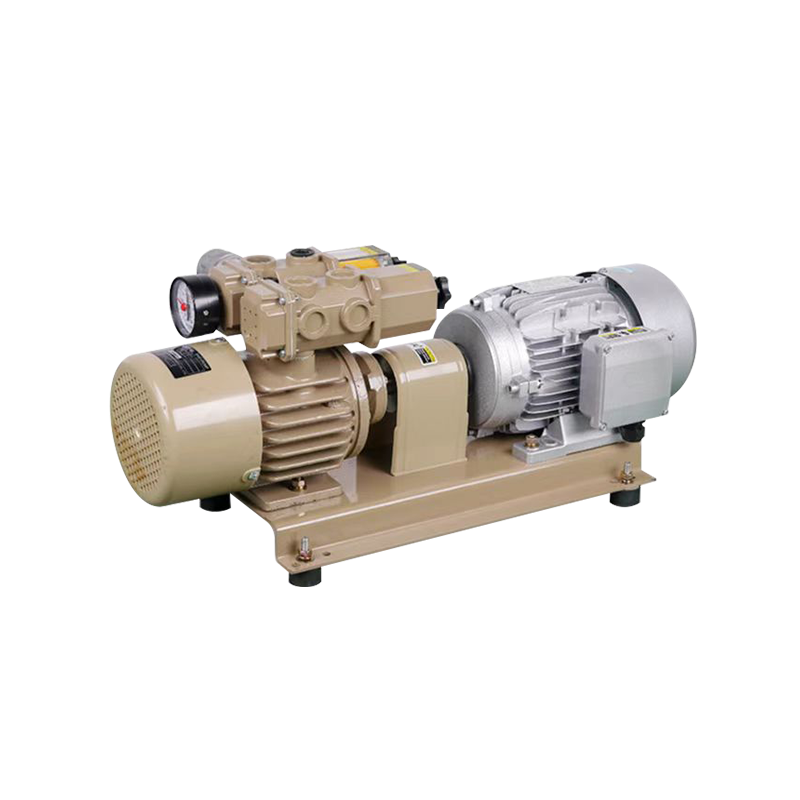

Industrial Electric Vacuum Pump Factory

The Electric Vacuum Pump offers a cutting-edge, oil-free vacuum solution designed to meet the stringent requirements of modern industrial and cleanroom applications. Utilizing advanced dry screw and rotary vane technologies, this pump provides reliable, high-performance vacuum generation without the contamination risks associated with oil-lubricated systems. Certified to ISO 8573-1 Class 0, it is ideal for critical processes such as medical sterilization, electronic coating, and precision packaging, where absolute cleanliness and air purity are essential.

Engineered for durability and efficiency, the pump features carbon-fiber-coated internal components and ceramic rotors with a 50,000-hour lifespan, significantly reducing downtime and maintenance costs. Its oil-free design not only extends operational life but also eliminates the need for oil changes, disposal, and the associated environmental concerns.

With over 40% higher energy efficiency compared to traditional oil-lubricated vacuum pumps, the Electric Vacuum Pump delivers substantial savings in long-term energy consumption—making it a sustainable and cost-effective solution for continuous-duty operations.

Whether used in cleanrooms, hospitals, electronics manufacturing, or food packaging lines, the Electric Vacuum Pump provides quiet, low-maintenance, and eco-friendly vacuum performance—setting a new standard for safety, reliability, and operational efficiency in high-demand environments.

Get Your Free Quote Now!

-

-

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When standard motors do n...

READ MORE -

Three-phase AC motors are widely used in industrial machinery, manufacturing lines, pumps, and HVAC systems. Selecting a reliable Three Phase AC Moto...

READ MORE -

AC electric motors are widely used in industries ranging from manufacturing to HVAC systems and household appliances. To ensure reliability and effic...

READ MORE

Electric Vacuum Pump in Modern Industries

The Electric Vacuum Pump has become a critical component across multiple industrial sectors due to its ability to generate consistent negative pressure while maintaining high operational efficiency. Unlike traditional mechanical pumps that rely solely on engine-driven mechanisms, electric vacuum pumps are powered independently, making them highly reliable and flexible in various applications. This independence ensures stable vacuum performance even under conditions where mechanical energy is limited, such as in modern energy-efficient systems.

From the perspective of a manufacturer, one of notable advantages of an electric vacuum pump is its precise control of vacuum pressure. By integrating advanced electronics, these pumps can be programmed to deliver consistent suction, reducing energy waste and ensuring longer product life. This is especially valuable in industries where stability and reliability directly affect production quality.

Industrial Electric Vacuum Pump: Built for Demanding Applications

The Industrial Electric Vacuum Pump is specifically engineered for heavy-duty use in factories, processing plants, and laboratories. These pumps are designed to handle continuous operation, high workloads, and demanding environments. Manufacturers emphasize durability by using high-quality materials such as corrosion-resistant alloys and advanced sealing technology. This ensures the pump can withstand exposure to chemicals, dust, and high operational temperatures without compromising performance.

Applications of the industrial electric vacuum pump include:

- Food and beverage packaging: ensuring air-tight sealing and extending shelf life.

- Pharmaceutical production: supporting sterile environments and precise fluid transfer.

- Electronics manufacturing: removing air pockets in semiconductor processes.

- Plastic and molding industries: aiding in air extraction to improve surface finish and structural integrity.

For buyers considering wholesale orders, manufacturers highlight the value of bulk procurement as it reduces downtime across multiple production lines while offering cost advantages.

High-Efficiency Electric Vacuum Pump: Energy-Saving Solution

One of the latest advancements is the High-Efficiency Electric Vacuum Pump, designed to minimize power consumption while improving output. These pumps utilize advanced motor technology, optimized rotor design, and intelligent control systems to reduce energy waste significantly. Compared to conventional models, high-efficiency pumps can cut energy usage by 20–40%, a factor that directly reduces operational costs for industries with round-the-clock requirements.

Another key feature is low noise and vibration performance. This makes high-efficiency electric vacuum pumps ideal for industries that demand a quiet working environment, such as laboratories, hospitals, or electronics assembly plants. Additionally, the optimized airflow and heat management systems ensure a longer life cycle, further reducing maintenance costs for end-users.

Advantages from a Manufacturer's Perspective

- Customization Options: Manufacturers offer tailor-made solutions, including variations in motor power, shaft length, and vacuum capacity, allowing buyers to choose pumps that precisely fit their production needs.

- Quality Assurance: Rigorous testing and adherence to international standards (such as ISO and CE certifications) ensure reliability.

- Scalability: Whether a buyer needs small units for laboratory use or large-scale systems for industrial plants, manufacturers provide scalable solutions.

- After-Sales Support: Technical support, training, and spare parts availability are crucial advantages that top manufacturers emphasize to attract long-term partnerships.

Industry Outlook and Buyer Considerations

The global demand for electric vacuum pumps is rising due to automation trends, stricter energy efficiency regulations, and the growing need for clean production processes. Industrial buyers are increasingly prioritizing high-efficiency electric vacuum pumps to meet sustainability goals while reducing operational expenses.

When purchasing, buyers should consider:

- Application environment (temperature, chemical exposure, operation cycles).

- Energy-saving potential of high-efficiency models.

- Maintenance and spare parts availability to minimize downtime.

- Manufacturer reliability for long-term cooperation.

The Electric Vacuum Pump, Industrial Electric Vacuum Pump, and High-Efficiency Electric Vacuum Pump represent modern engineering solutions that balance performance, durability, and energy efficiency. From packaging and pharmaceuticals to electronics and plastics, these pumps are redefining operational standards across industries. Manufacturers continue to innovate by offering customizable, energy-efficient, and reliable solutions, making them the preferred choice for buyers seeking long-term value and high productivity.