Single phase AC motors are commonly used in homes, small industries, and light commercial applications. These motors operate on a single-phase alterna...

READ MORE

- Y2 Series Three-Phase Asynchronous Motor

- YE3 Series High Efficiency Three-Phase Asynchronous Motor

- YCL Series Double Value Capacitor Asynchronous Motor

- YL Series Double Value Capacitor Asynchronous Motor

- YY Series Capacitor Run Asynchronous Motor

- Customized Long Shaft Motor

- YE4 Series High Efficiency Three-Phase Asynchronous Motor

- Electric Vacuum Pump

- High Pressure Washer

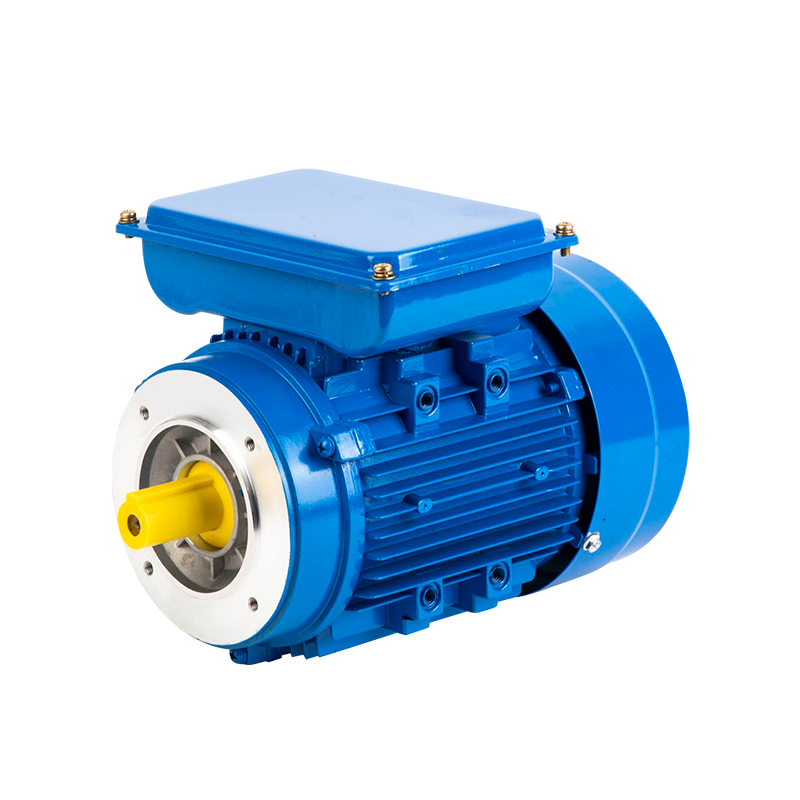

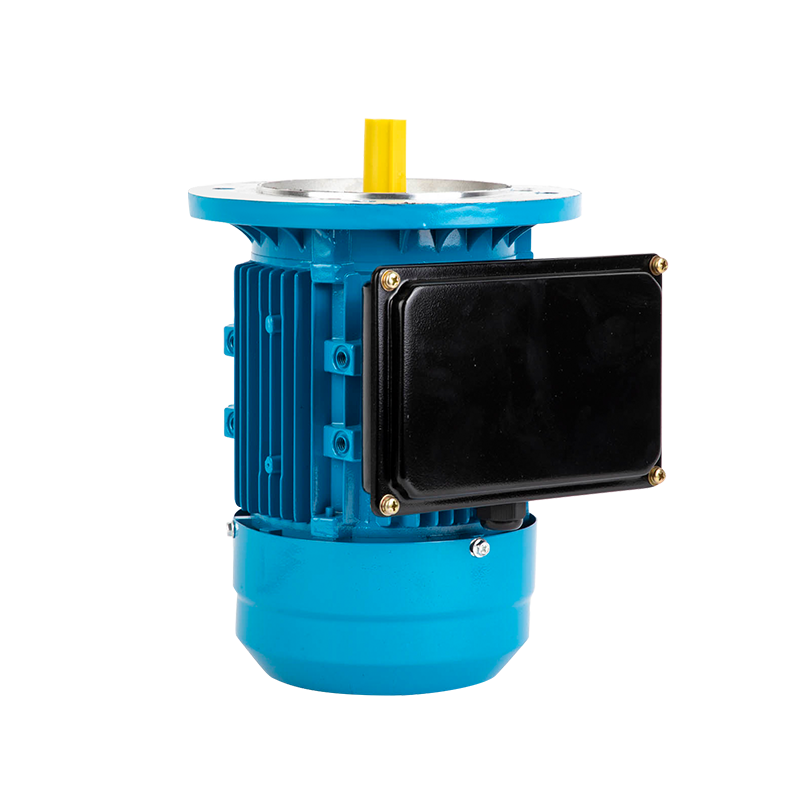

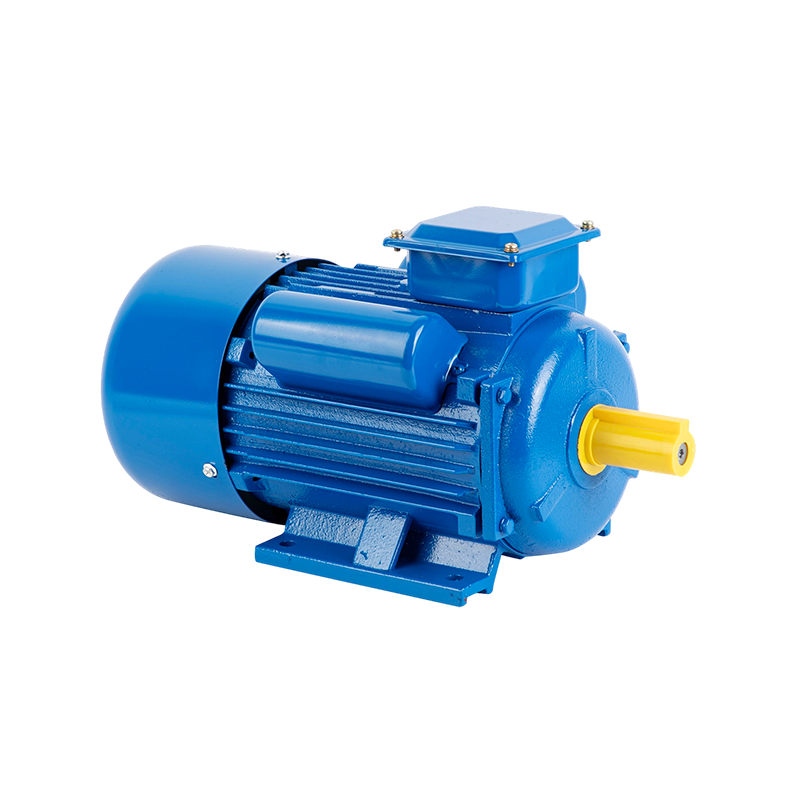

YE4 Series High Efficiency Motor Maker

The YE4 Series High Efficiency Three-Phase Asynchronous Motor is a next-generation industrial motor designed to meet—and exceed—international energy efficiency standards. As an IE4-class motor, it delivers outstanding energy-saving performance, making it an ideal choice for companies aiming to reduce operational costs and minimize environmental impact. This motor is suitable for driving a wide range of general-purpose machinery, such as compressors, fans, pumps, and other mechanical equipment. It is also widely used in industries including oil, chemical processing, pharmaceuticals, and mining.

Built for durability and high performance, the YE4 motor features a well-balanced design with low noise, minimal vibration, and thermal stability. Its attractive and compact structure allows for easy installation and convenient operation, making it a dependable component for both new installations and system upgrades.

Designed for use in environments where the altitude does not exceed 1000 meters and the ambient temperature ranges from -15°C to +40°C, the YE4 motor ensures consistent performance across varying seasonal conditions. Its enhanced efficiency and robust construction make it a smart and sustainable choice for long-term industrial applications.

Get Your Free Quote Now!

-

-

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When standard motors do n...

READ MORE -

Three-phase AC motors are widely used in industrial machinery, manufacturing lines, pumps, and HVAC systems. Selecting a reliable Three Phase AC Moto...

READ MORE -

AC electric motors are widely used in industries ranging from manufacturing to HVAC systems and household appliances. To ensure reliability and effic...

READ MORE

1. What is a Customized Long Shaft Motor?

A Customized Long Shaft Motor is a specialized electric motor designed with an extended shaft length beyond standard dimensions. This longer shaft enables the motor to drive equipment located farther from the mounting point or to integrate seamlessly into compact machinery where direct coupling is essential. By offering custom shaft lengths, diameters, and materials, manufacturers can adapt the motor to fit pumps, mixers, blowers, conveyors, or even precision equipment. For buyers, the value lies in the flexibility. a motor with a long shaft reduces the need for additional couplings or transmission parts, lowering overall costs while ensuring higher efficiency.

2. Why choose a Motor With Long Shaft over a standard motor?

A Motor With Long Shaft offers unique operational advantages:

- Direct Drive Capability. Longer shafts make it easier to connect the motor directly to fans, impellers, or blades without additional adapters.

- Reduced Vibration. Fewer transmission parts mean less imbalance and smoother performance.

- Space Efficiency. Ideal for tight spaces where an extended shaft eliminates the need for extra mechanical components.

- Customization. Buyers can specify shaft extensions, grooves, keyways, or stainless-steel finishes to suit demanding industrial environments.

These benefits explain why long shaft designs are popular among OEMs and bulk equipment integrators in HVAC, food processing, agriculture, and marine industries.

3. What industries use a Long Shaft Engine?

A Long Shaft Engine finds wide application across industries where durability and reliability are critical:

- Water Pumps and Submersible Units. The extended shaft design allows the motor to remain above water while the pump impeller operates below.

- Mixing and Agitation Systems. Long shaft motors are good for stirring chemicals, paints, or food products in deep tanks.

- Ventilation and Blower Units. Extended shafts provide direct drive for fans, improving airflow efficiency.

- Marine and Offshore Equipment. Long shaft engines withstand harsh conditions while delivering torque for propellers or hydraulic pumps.

For wholesalers, this means a broad customer base and repeat demand in multiple verticals.

4. Can a Customized Long Shaft Motor handle heavy-duty workloads?

Yes. Modern Customized Long Shaft Motors are built using premium bearings, reinforced housings, and precision balancing techniques. These features allow them to handle continuous duty (S1 rating) and withstand high radial or axial loads. Many models also include IP55 or IP65 protection ratings, ensuring performance even in dusty or wet environments. This robustness makes them a reliable choice for buyers looking for bulk procurement in construction, manufacturing, and energy sectors.

5. How do buyers benefit from ordering long shaft motors in bulk?

Wholesale procurement of Motors With Long Shaft offers several advantages:

- Cost Savings. Bulk orders reduce per-unit manufacturing and shipping costs.

- Consistent Supply. A steady inventory ensures uninterrupted production for OEMs and distributors.

- Customization at Scale. Manufacturers can deliver shaft modifications, coatings, and special mounting types more efficiently in large batches.

- Branding Opportunities. OEM buyers can request customized labeling, packaging, and specifications to build their own product lines.

This makes long shaft motors an attractive option for distributors and integrators seeking competitive pricing and differentiation in the marketplace.

6. What customization options are available for a Long Shaft Engine?

Manufacturers typically provide:

- Shaft Length & Diameter Adjustments

- Keyway, Thread, or Hollow Shaft Designs

- Material Choices (steel, stainless steel, coated shafts)

- Voltage & Frequency Adaptability (50Hz/60Hz, global use)

- Mounting Configurations (B3, B5, B35, flange or foot mounted)

- Special Surface Treatments to resist corrosion in marine or chemical environments.

These customization options ensure that every Long Shaft Engine fits the exact needs of the application.