An AC Electric Motor is a widely used device in industrial, commercial, and domestic applications. Its primary function is to convert electrical energ...

READ MORE

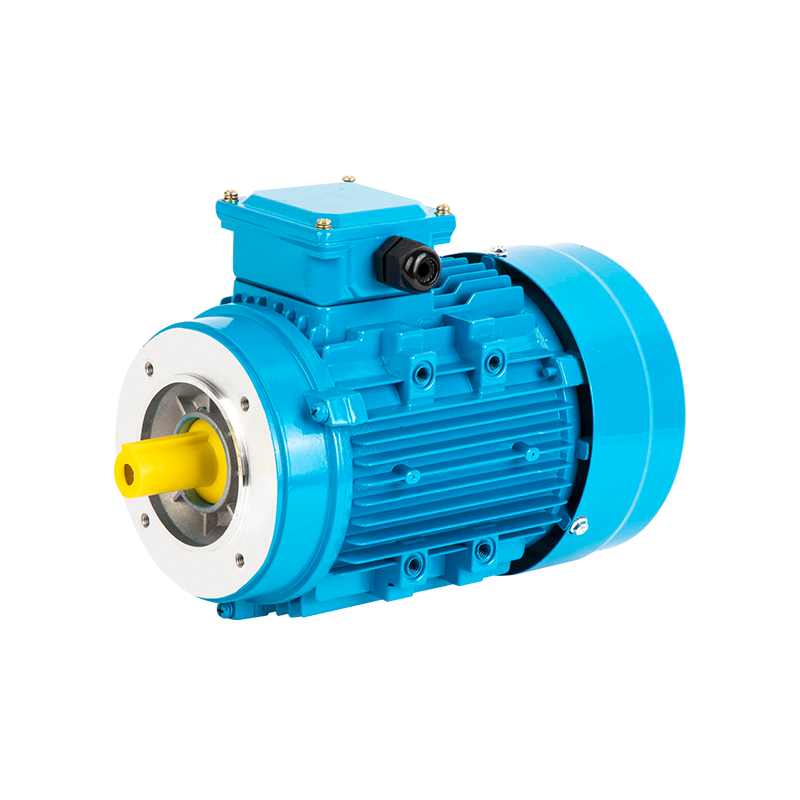

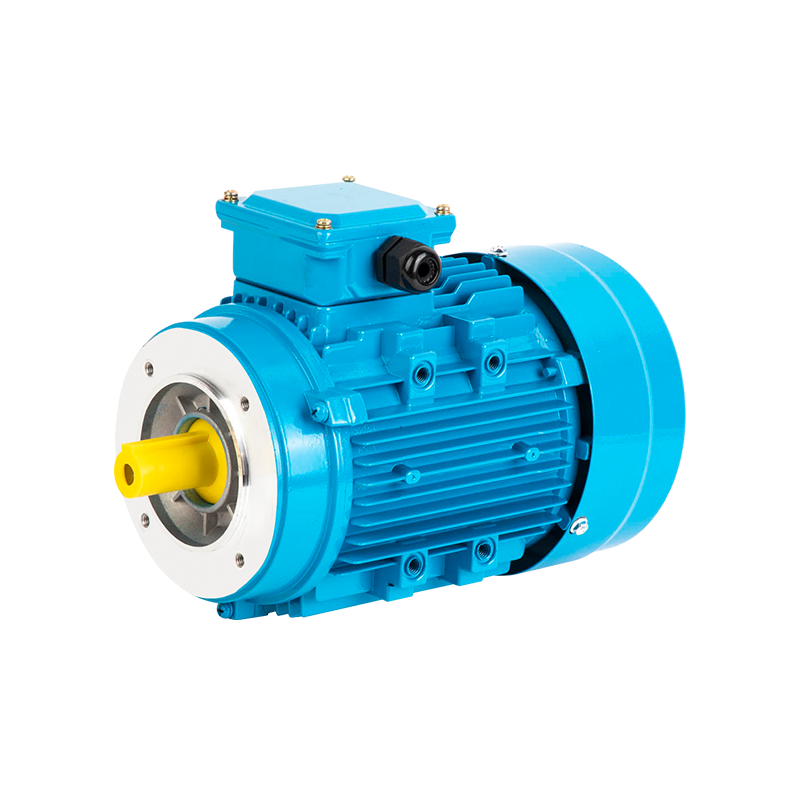

- Y2 Series Three-Phase Asynchronous Motor

- YE3 Series High Efficiency Three-Phase Asynchronous Motor

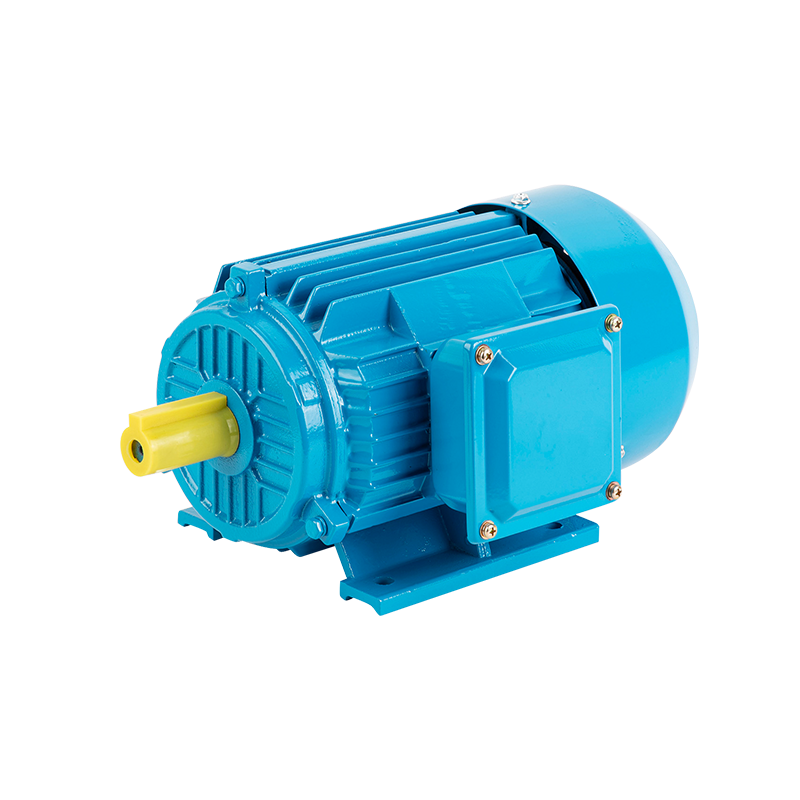

- YCL Series Double Value Capacitor Asynchronous Motor

- YL Series Double Value Capacitor Asynchronous Motor

- YY Series Capacitor Run Asynchronous Motor

- Customized Long Shaft Motor

- YE4 Series High Efficiency Three-Phase Asynchronous Motor

- Electric Vacuum Pump

- High Pressure Washer

Single Phase AC Motor

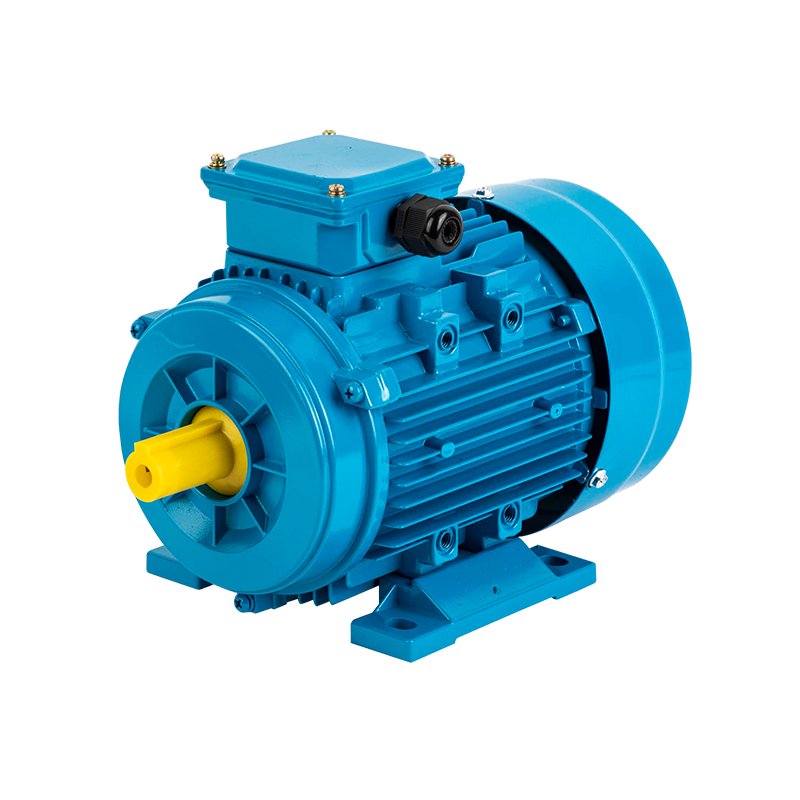

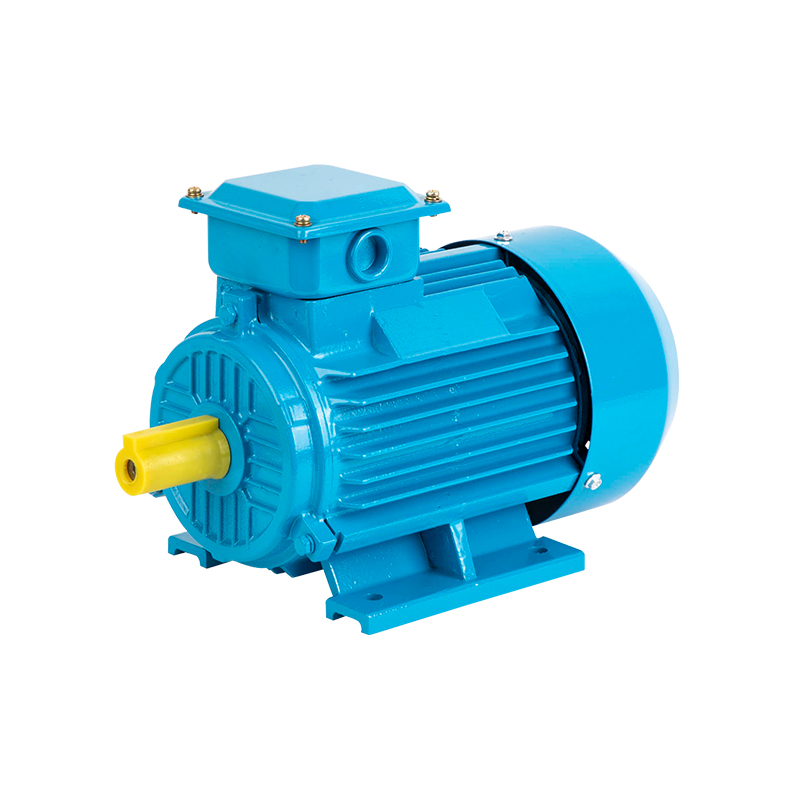

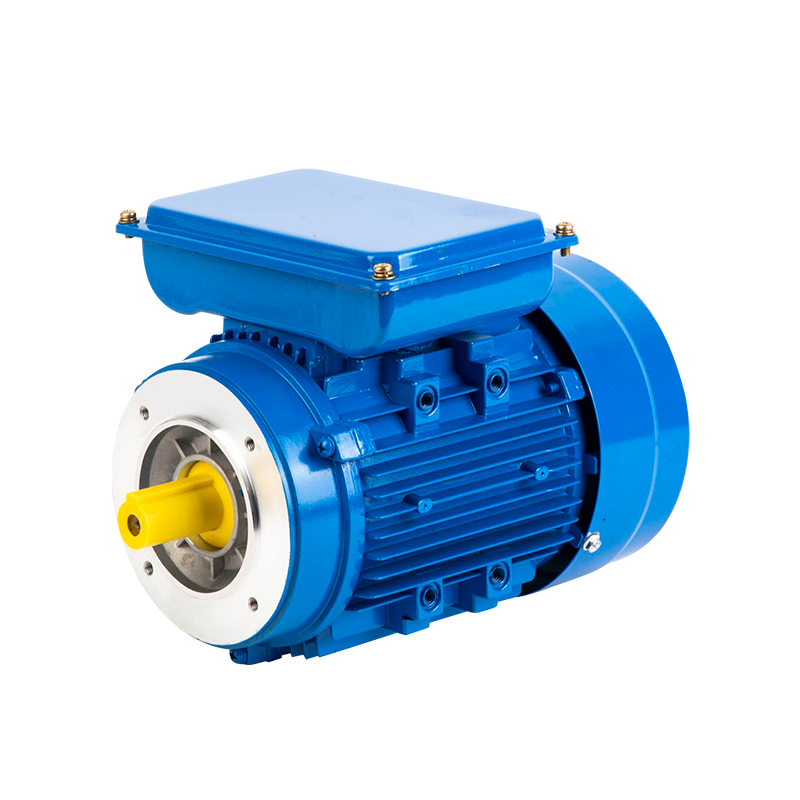

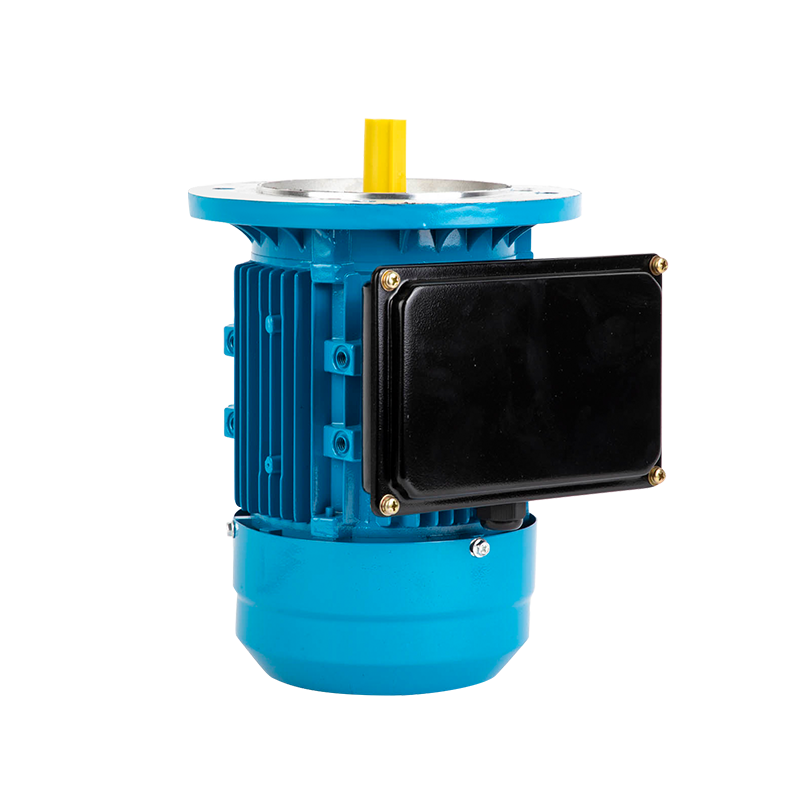

Three-phase electric motors are an essential component in a wide range of industrial, commercial, and residential applications. Renowned for their reliability, efficiency, and robustness, these motors are designed to provide continuous power for demanding machinery and equipment. Whether you're powering a conveyor belt, pump, or compressor, the Three Phase Electric Motor is engineered to deliver consistent performance over long periods, making it an ideal choice for industries that rely on constant and heavy-duty motor operation.

Efficient Power Delivery

One of the primary advantages of the Three Phase Electric Motor is its ability to provide efficient power delivery. Unlike single-phase motors, which rely on a single current, three-phase motors utilize three separate currents that are offset by 120 degrees. This results in a smooth, balanced, and uninterrupted power flow, reducing vibrations and ensuring that the motor operates more efficiently. With lower power loss and higher torque output, these motors are able to handle heavy loads and operate for longer periods without overheating, making them suitable for everything from industrial machinery to HVAC systems.

Versatility Across Industries

Three-phase electric motors are used in a broad spectrum of industries. In manufacturing, these motors power equipment such as pumps, fans, compressors, and conveyors. They are also integral to HVAC systems, where they drive the compressors and air handlers that regulate heating, ventilation, and air conditioning. In the agricultural sector, three-phase electric motors are often used to operate irrigation systems, feed conveyors, and grain mills. Additionally, in the mining and construction industries, these motors are used to power heavy equipment such as crushers, drills, and lifts.

The versatility of Three Phase Electric Motors also extends to commercial settings, where they are commonly found in elevators, escalators, and refrigeration units. These motors can be customized in terms of speed, power rating, and voltage to meet the specific requirements of different applications. Whether you're designing a custom industrial setup or upgrading existing equipment, the Three Phase Electric Motor is an choice for providing consistent and reliable performance.

Durability and Longevity

Durability is one of the standout features of the Three Phase Electric Motor. Built to withstand the rigors of industrial environments, these motors are designed with high-quality materials to ensure long service life. With proper maintenance, a well-built three-phase motor can operate for decades without the need for major repairs or replacements. This reliability is crucial for reducing downtime in manufacturing plants or commercial facilities, where equipment failure can to costly interruptions.

The robust construction of these motors also means they are able to handle operating conditions. Whether exposed to high temperatures, moisture, or dust, Three Phase Electric Motors are built to perform reliably in tough environments. Their rugged design minimizes wear and tear, ensuring a longer lifespan and reducing the need for frequent maintenance.

Energy Efficiency and Cost Savings

Energy efficiency is a key consideration for businesses looking to reduce operational costs. The Three Phase Electric Motor is known for its energy-efficient design, which helps lower electricity consumption. Since three-phase motors are more efficient than their single-phase counterparts, they reduce the amount of energy wasted during operation. This can result in significant cost savings over time, especially for industries with high energy demands.

Furthermore, the higher efficiency of these motors contributes to a reduction in overall carbon footprint. By consuming less energy, businesses can reduce their environmental impact, aligning with global efforts to minimize energy consumption and reduce greenhouse gas emissions. Whether you're focused on improving profitability or striving for sustainability, investing in energy-efficient Three Phase Electric Motors can be a smart business decision.

Ease of Maintenance and Serviceability

Maintenance is another key factor that makes the Three Phase Electric Motor a popular choice for industrial applications. With fewer parts subject to wear and tear, these motors require less frequent maintenance compared to other types of motors. In addition, their straightforward design makes them easy to service, with readily available replacement parts. Routine maintenance tasks such as lubrication, cleaning, and inspections are simple to perform, which helps extend the motor’s lifespan and ensure performance.

Get Your Free Quote Now!

-

-

Single phase AC motors are commonly used in homes, small industries, and light commercial applications. These motors operate on a single-phase alterna...

READ MORE -

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When standard motors do n...

READ MORE -

Three-phase AC motors are widely used in industrial machinery, manufacturing lines, pumps, and HVAC systems. Selecting a reliable Three Phase AC Moto...

READ MORE

1. What are the main advantages of a Three Phase AC Motor compared to other motor types?

As a manufacturing factory specializing in electric motors, we often recommend the Three Phase AC Motor for industrial applications where consistent performance and high efficiency are required. This motor design provides smoother torque, less vibration, and greater power output compared to single-phase motors. From our production perspective, the Three Phase AC Motor also allows for a more compact structure, reduced copper usage per kilowatt of power, and improved energy efficiency. For factories, this translates to lower operational costs and higher reliability. In heavy-duty machinery, conveyors, compressors, and pumps, the durability and longevity of the three-phase design make it choice for customers seeking robust solutions.

2. When should customers choose a Single Phase AC Motor?

The Single Phase AC Motor is widely used in applications where power demand is relatively lower or where only single-phase electricity supply is available. As a manufacturer, we design and produce these motors to cater to residential, light commercial, and small-scale industrial needs. Typical applications include fans, small pumps, household appliances, and portable machinery. From the factory standpoint, Single Phase AC Motors are valued for their simpler wiring, lower initial investment, and ease of installation. While they do not match the power efficiency of three-phase designs, our engineering team ensures that the performance is optimized for cost-sensitive applications, providing a balance of affordability and reliability.

3. How is a Vacuum Pump Motor different from general-purpose AC motors?

The Vacuum Pump Motor is a specialized design that supports vacuum generation systems used in industries such as medical equipment, laboratory devices, packaging, and semiconductor manufacturing. Unlike general-purpose motors, our Vacuum Pump Motors are engineered with precise tolerances, high heat resistance, and long operation stability under continuous load. From a manufacturer's perspective, we place emphasis on tight integration between the motor and pump system to achieve low noise, reduced vibration, and enhanced vacuum efficiency. Additionally, the motor's insulation and lubrication systems are optimized to withstand demanding conditions, ensuring reliable performance in critical applications where downtime is not acceptable.

4. What factors should customers consider when choosing between a Three Phase AC Motor and a Single Phase AC Motor?

From our factory experience, the key factors include power requirements, availability of electrical supply, cost considerations, and the intended application. Three Phase AC Motors are ideal for high-power machinery such as industrial fans, compressors, and conveyor systems. On the other hand, Single Phase AC Motors are practical where only household or light commercial power supplies are available. We advise customers to also consider long-term operating costs: while the Single Phase AC Motor is cheaper initially, the Three Phase AC Motor often provides higher energy efficiency and reduced maintenance costs over time. Our production team tailors both motor types with customer-specific requirements, ensuring good performance for each unique scenario.

5. Why do manufacturing factories focus on quality testing for Vacuum Pump Motors?

In our production line, Vacuum Pump Motors undergo rigorous quality testing because their performance directly impacts sensitive processes. A small deviation in motor efficiency or stability could cause insufficient vacuum levels, which in turn affects product quality in industries like electronics or pharmaceuticals. As a responsible manufacturer, we conduct endurance tests, vibration analysis, insulation resistance checks, and thermal performance evaluations. This ensures that every Vacuum Pump Motor shipped from our facility meets international standards. By focusing on precision and durability, we provide our global clients with motors they can rely on for uninterrupted operations.

6. How does a manufacturer ensure customization options for AC motors?

Many of our customers require motors with specific voltages, shaft designs, mounting types, or protective enclosures. Our factory specializes in customizing Three Phase AC Motors, Single Phase AC Motors, and Vacuum Pump Motors according to client specifications. For example, a customer in the HVAC industry may need compact Single Phase AC Motors with thermal protection, while a packaging machinery company may request high-speed Vacuum Pump Motors with low noise levels. By leveraging advanced CNC machining, automated winding systems, and strict quality inspection, we ensure each customized motor meets both performance expectations and safety standards.